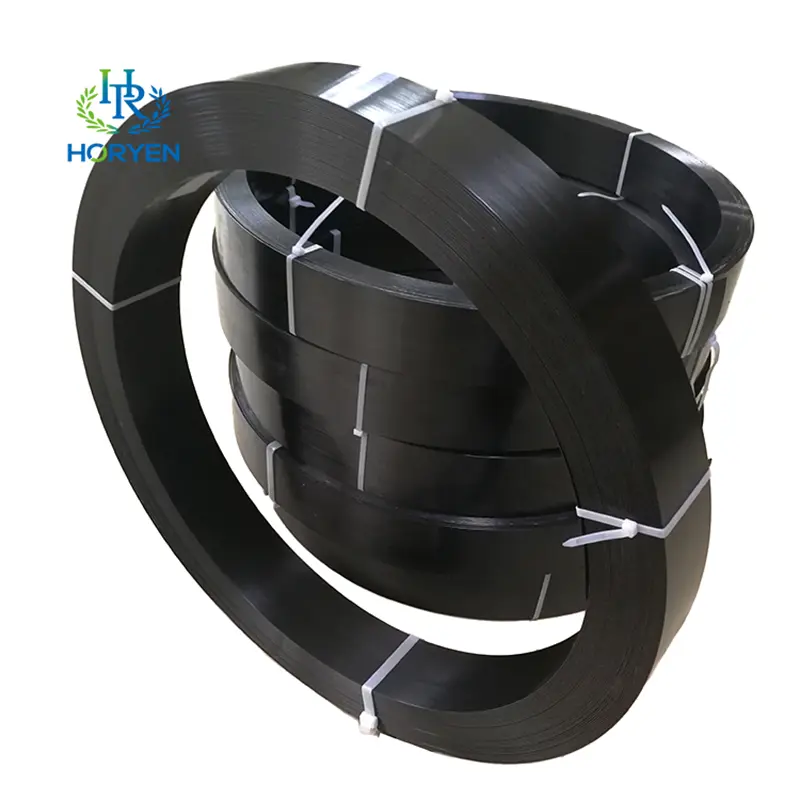

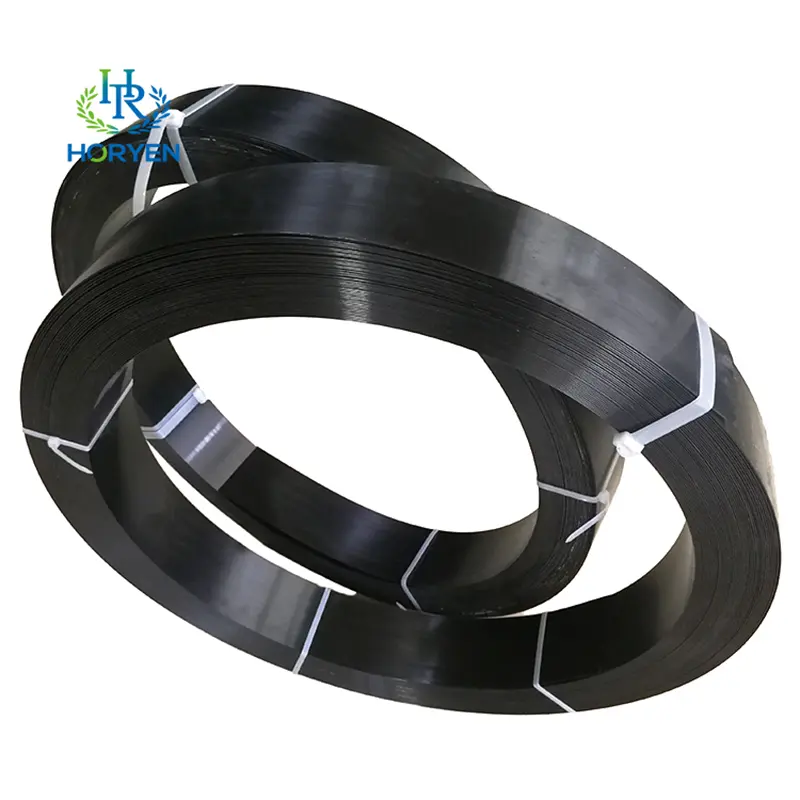

1.0mm 1.2mm 1.4mm Pultruded UD Carbon Fiber Plate

Product Feature

1. High strength and high efficiency

2. Light weight and good flexibility

3. Convenient construction

4. Good durability and corrosion resistance

|

Product Information |

|

|

Product Type |

Pultrusion carbon fiber plate |

|

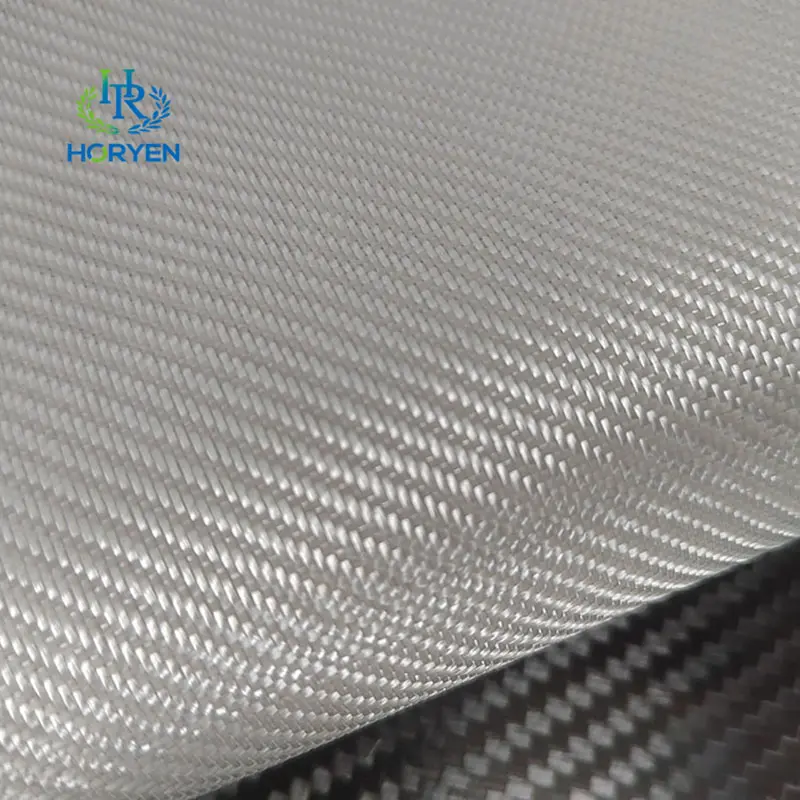

Material |

Carbon fiber yarn and epoxy resin |

|

Thickness |

1.0mm,1.2mm,1.4mm,2.0mm,3.0mm |

|

Width |

50mm,100mm,200mm... |

|

Application |

Building repair,construction,bridge reinforcement |

|

Tensile strength |

2000Mpa or 2400Mpa |

|

Modulus |

140Gpa or 160Gpa |

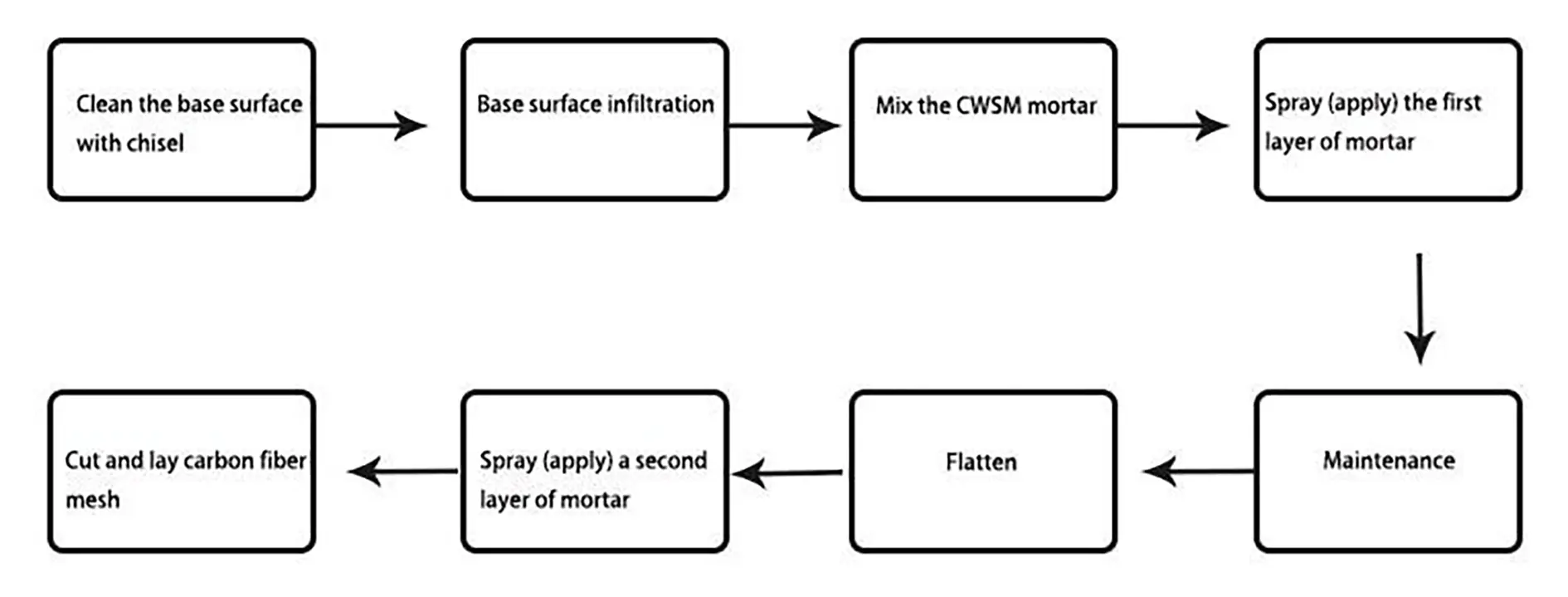

Construction Process

1. Concrete surface treatment.

2. Remove all dirt (dust, grease and surface covering) from the bonding surface of carbon fiber board by grinding or other methods until the solid base surface is exposed, and ensure the flatness of the base surface. After treatment, clean the surface with industrial vacuum cleaner or acetone.

3. Apply a layer of 4-5mm structural adhesive on the concrete base surface with a scraper, and then apply 1-2mm thick structural adhesive on the carbon plate.

4. Gently press and paste the carbon fiber board coated with bonding resin on the position to be pasted. Use rubber roller to compact evenly and stably along the fiber direction, so that the resin overflows from both sides to ensure compactness and no cavity. When multiple carbon fiber boards are pasted in parallel, the gap between the two boards shall not be less than 5mm.

5. Finally, remove the excess adhesive and clean the edge part (carbon fiber boardcan’t be rolled or dragged on the ground without a protective layer to avoid damage to the carbon fiber board surface).

More Choice

Application Field

Bending and shear reinforcement of concrete beams, reinforcement of concrete floors and Bridge Slabs, reinforcement of concrete,reinforcement of piers, piles and other columns, reinforcement of chimneys, tunnels, water pools, concrete pipes and so on. In addition, it is also widely used in the production of multi rotor UAV fuselage, such as traversing aircraft, aerial photography UAV and so on.

Why Choose Us?

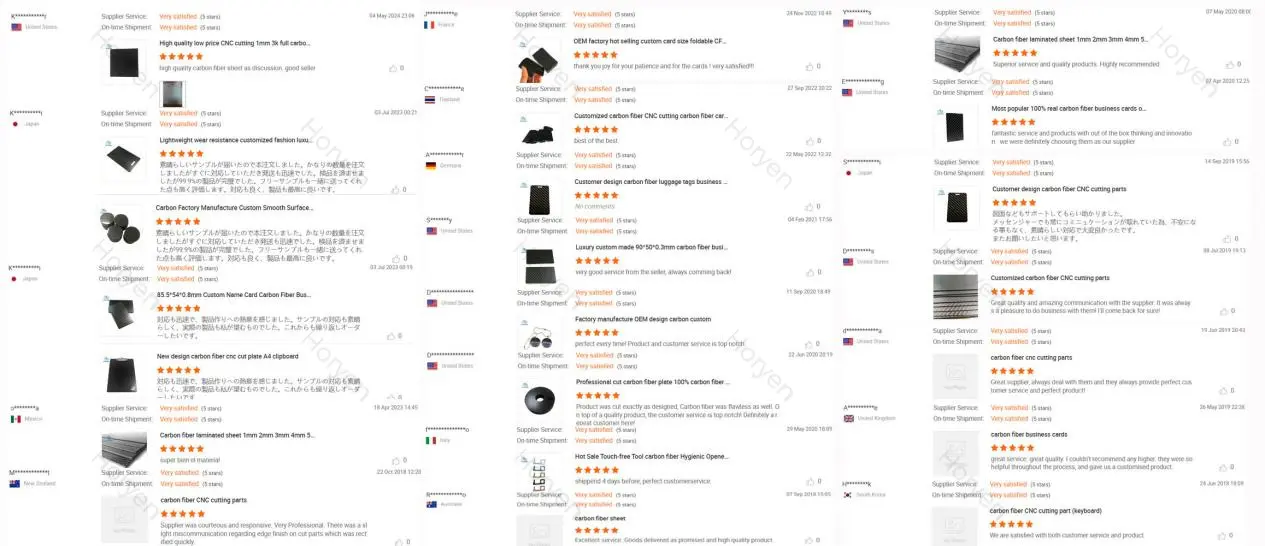

Buyer Review

Our Factory

Packing & Transportation

FAQ

Flow Chart