01

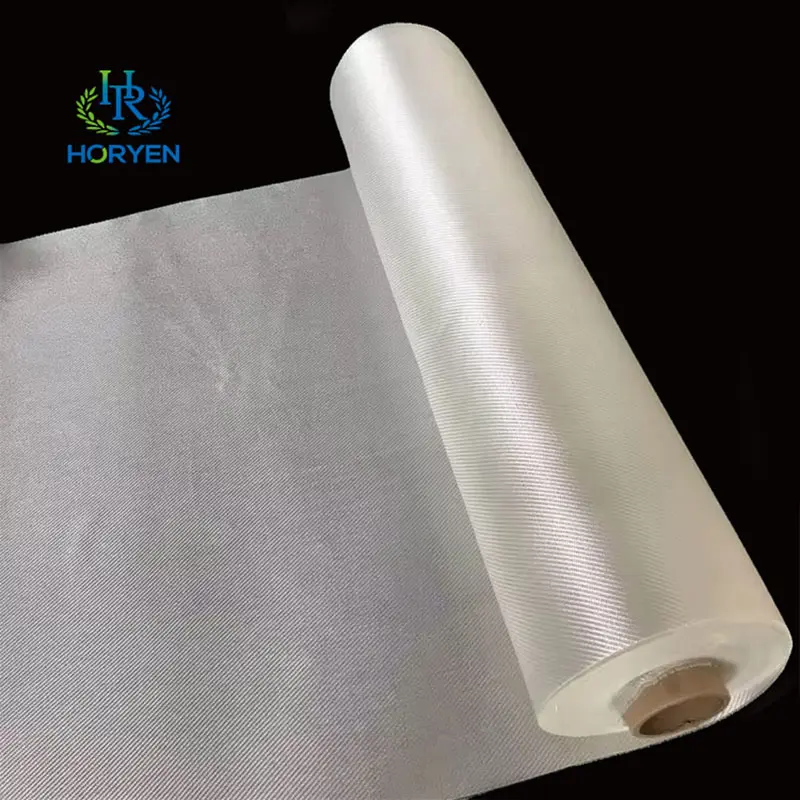

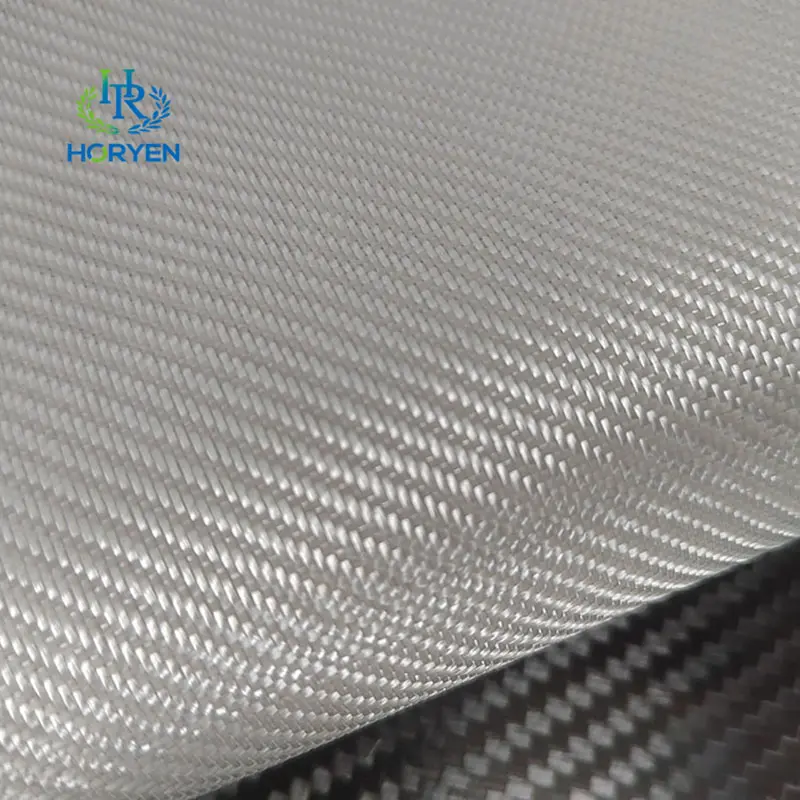

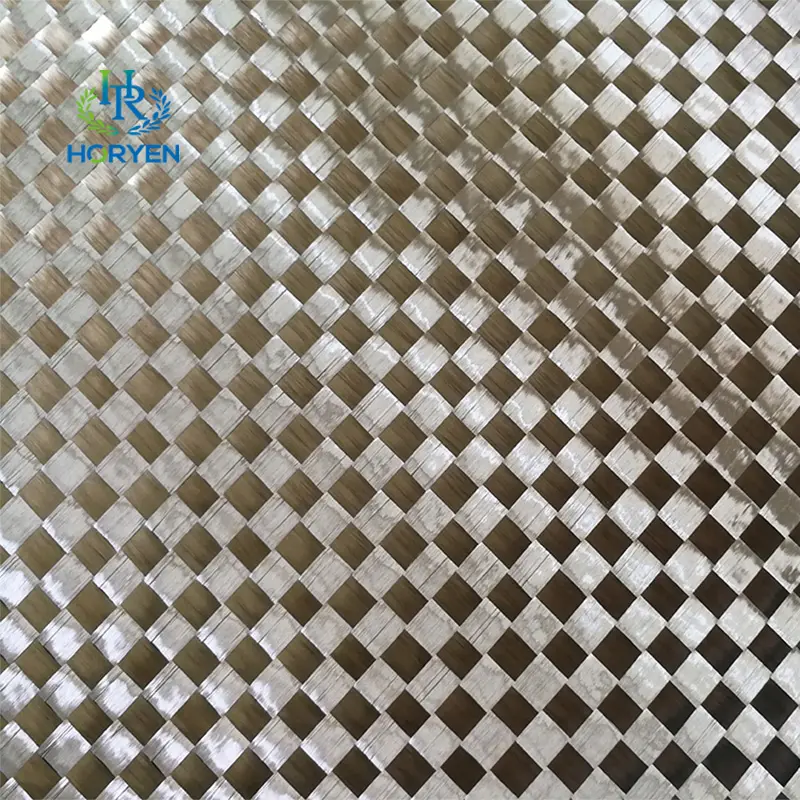

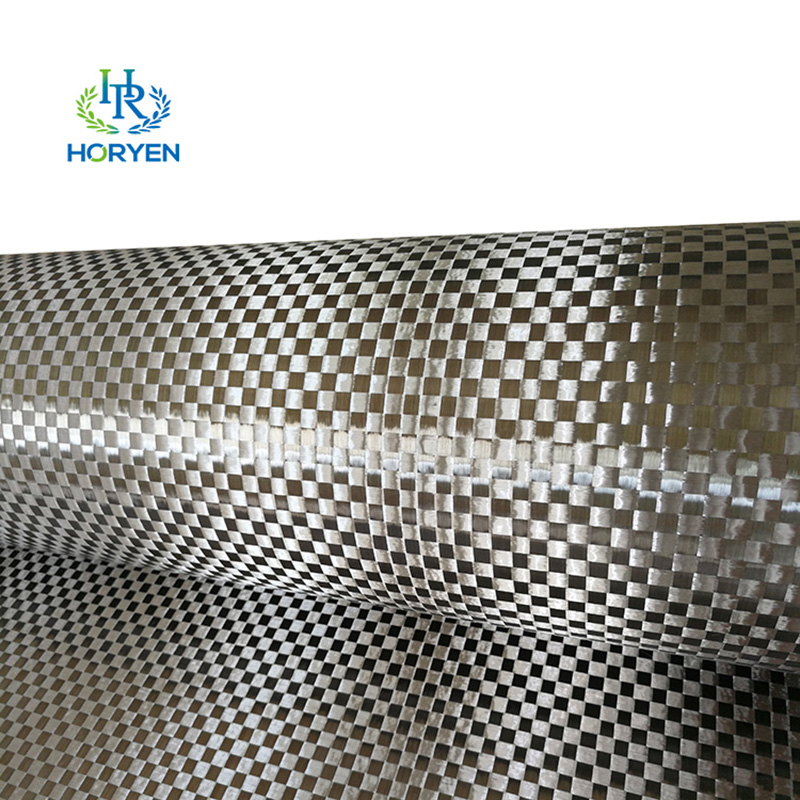

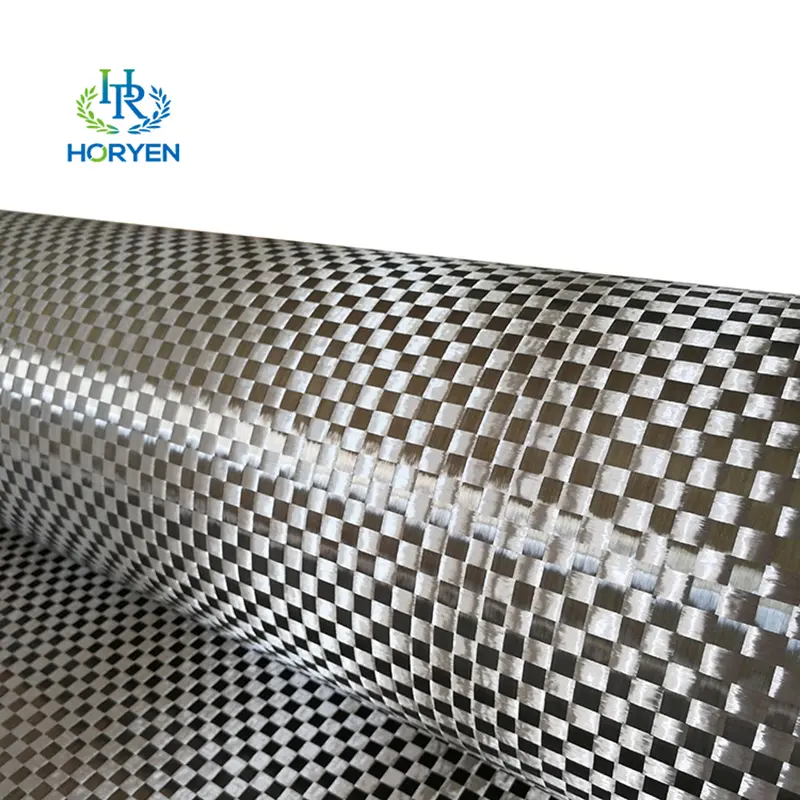

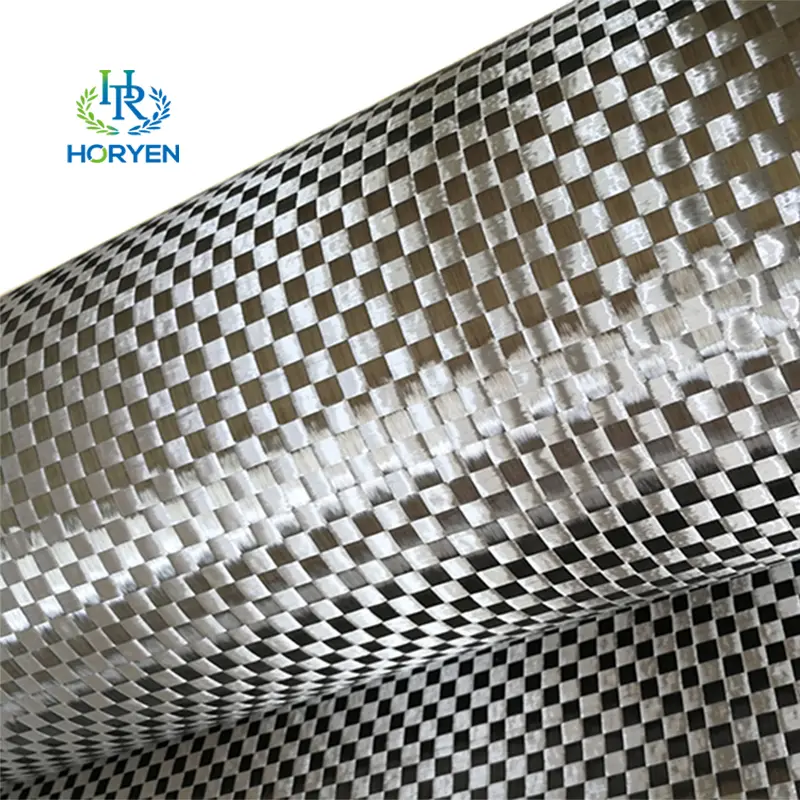

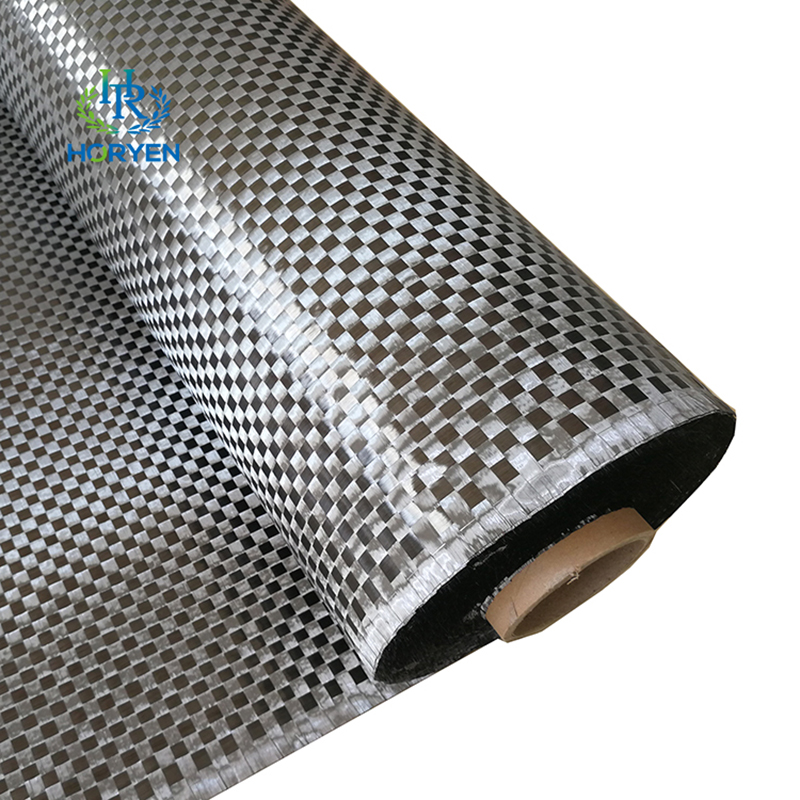

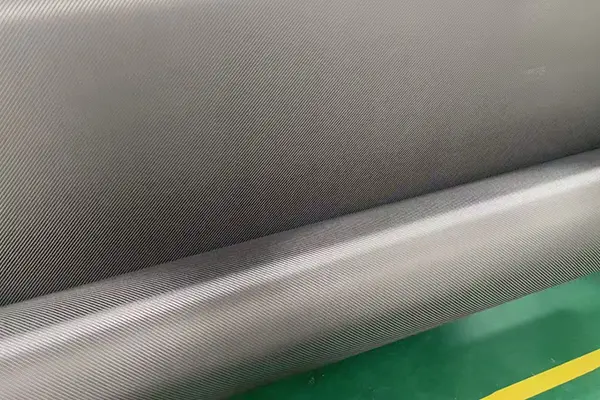

12K 200gsm Plain Spread Tow Carbon Fiber Cloth Roll

Product Feature

●Impact resistance and delamination resistance: The fiber layers are tightly bonded, reducing stress concentration points and effectively dispersing energy when impacted, thereby reducing the risk of delamination.

●Fatigue resistance: Low porosity and uniform structure delay crack propagation, extend the service life of materials under dynamic loads, and are suitable for high cycle working conditions such as wind blades and robotic arms.

●Dimensional stability: The low thermal expansion coefficient of carbon fiber itself combined with the uniform structure of the widened cloth makes the composite material deform less in temperature difference environments.

●Fatigue resistance: Low porosity and uniform structure delay crack propagation, extend the service life of materials under dynamic loads, and are suitable for high cycle working conditions such as wind blades and robotic arms.

●Dimensional stability: The low thermal expansion coefficient of carbon fiber itself combined with the uniform structure of the widened cloth makes the composite material deform less in temperature difference environments.

|

Product Information |

|

|

Product Type |

12k Spread Tow Carbon Fiber Fabric |

|

Material |

100% carbon fiber |

|

Fabric Type |

Cloth |

|

Warp |

12K |

|

FAW |

200gsm |

|

Color |

Black |

|

Width |

100cm |

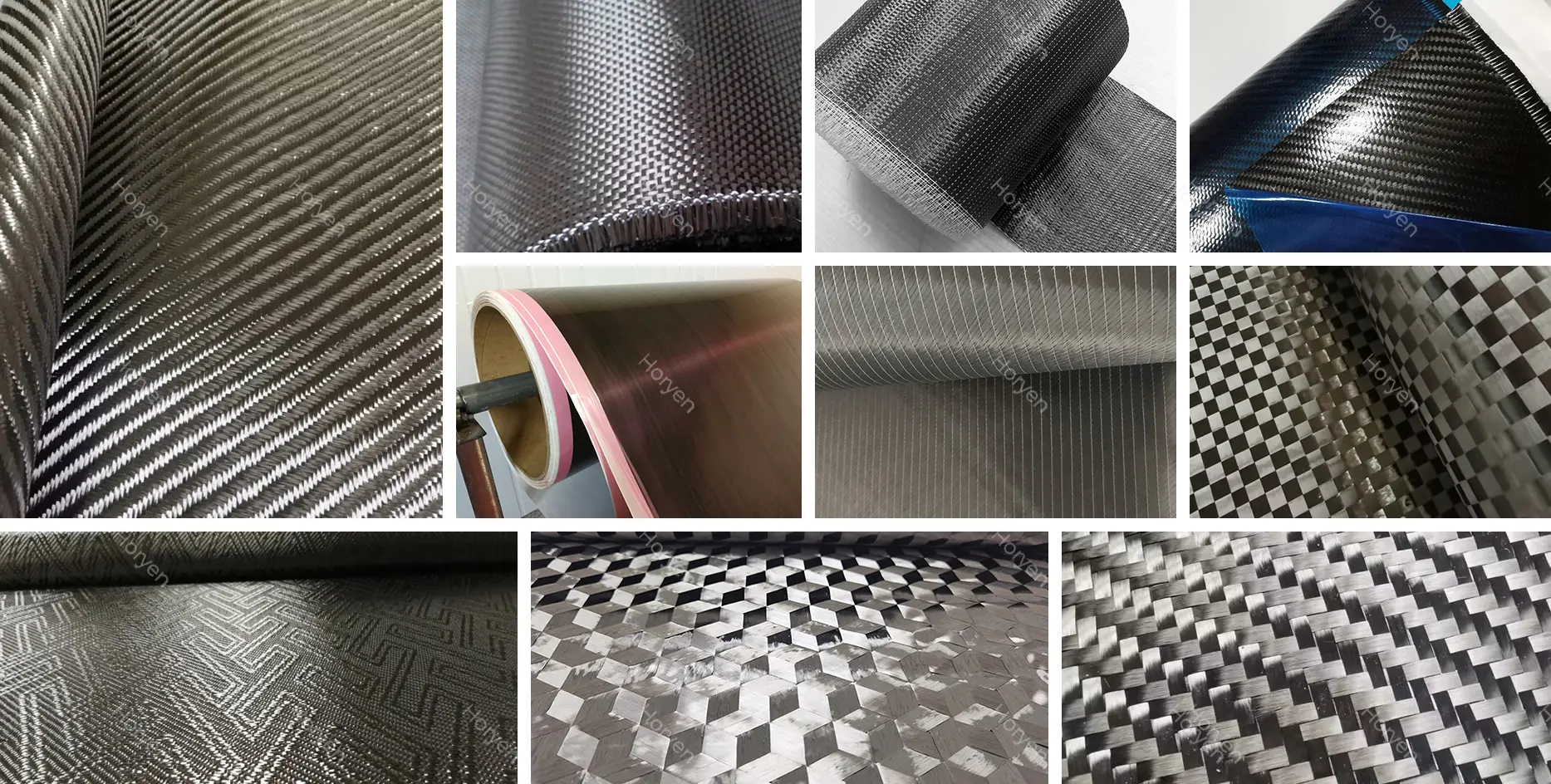

More Choice

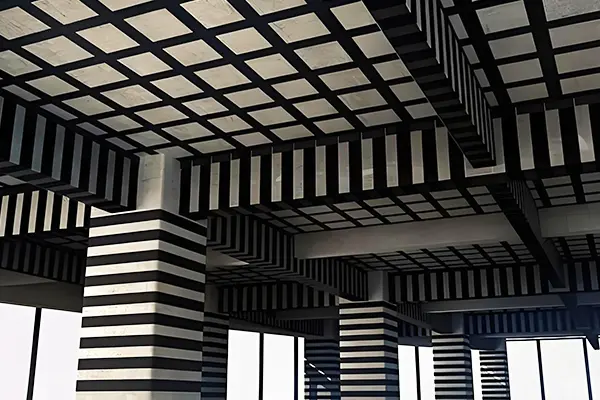

Application Field

Aircraft structural components:

★Wing skin: Utilizing the ultra-thin characteristics of widened fabric (single layer thickness of 0.02-0.1mm) and uniform fiber distribution, a lightweight and high-strength wing surface is manufactured to reduce flight resistance and improve fuel efficiency.

★Airframe frame and cabin walls: Through multi axial layered design (such as 0 °/± 45 ° combination), the impact resistance and fatigue resistance are optimized to meet the long-term dynamic load requirements of the aircraft.

★Satellite and rocket components: used for satellite mounts, fairings, etc., with their high specific stiffness and low thermal expansion coefficient, ensure dimensional stability in extreme temperature difference environments.

★Wing skin: Utilizing the ultra-thin characteristics of widened fabric (single layer thickness of 0.02-0.1mm) and uniform fiber distribution, a lightweight and high-strength wing surface is manufactured to reduce flight resistance and improve fuel efficiency.

★Airframe frame and cabin walls: Through multi axial layered design (such as 0 °/± 45 ° combination), the impact resistance and fatigue resistance are optimized to meet the long-term dynamic load requirements of the aircraft.

★Satellite and rocket components: used for satellite mounts, fairings, etc., with their high specific stiffness and low thermal expansion coefficient, ensure dimensional stability in extreme temperature difference environments.

UAV:

★The lightweight fuselage and rotor structure can extend the endurance time, while the high-strength characteristics ensure structural reliability during high-speed flight.

Why Choose Us?

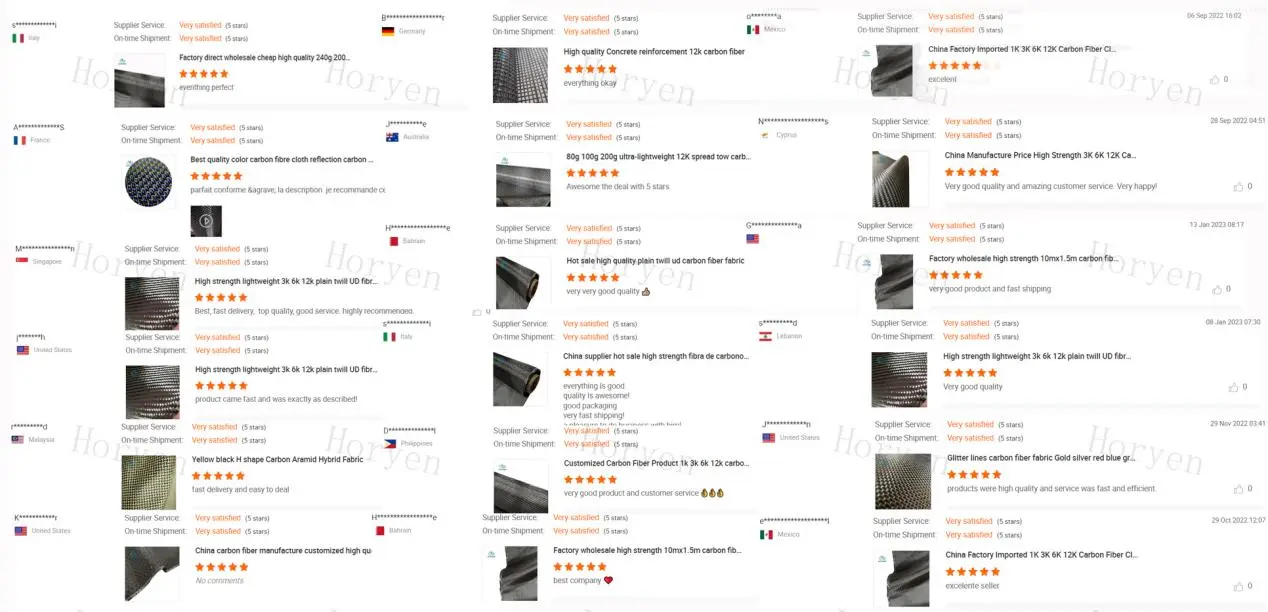

Buyer Review

Our Factory

Packing & Transportation

FAQ

Product Parameter

| Product Information | |||||

| Product Type | 3D Triaxial Spread Tow Fabric | ||||

| Material | 100% carbon fiber | ||||

| Fabric Type | Cloth | ||||

| Warp | Customized | ||||

| FAW | Customized | ||||

| Thickness | Customized | ||||

| Color | Black | ||||

| Width | Customized | ||||