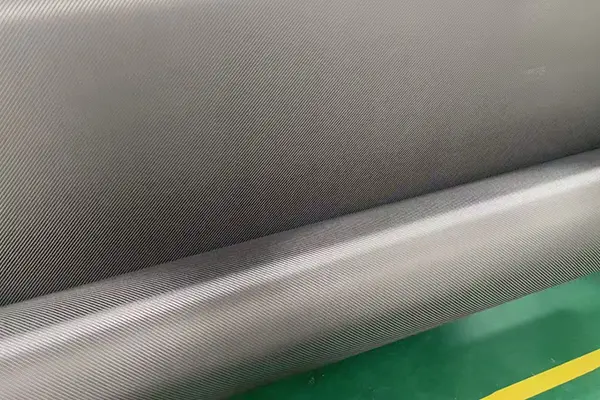

3K 12K Epoxy Resin Unidirectional Prepreg Carbon Fiber Cloth

Product Feature

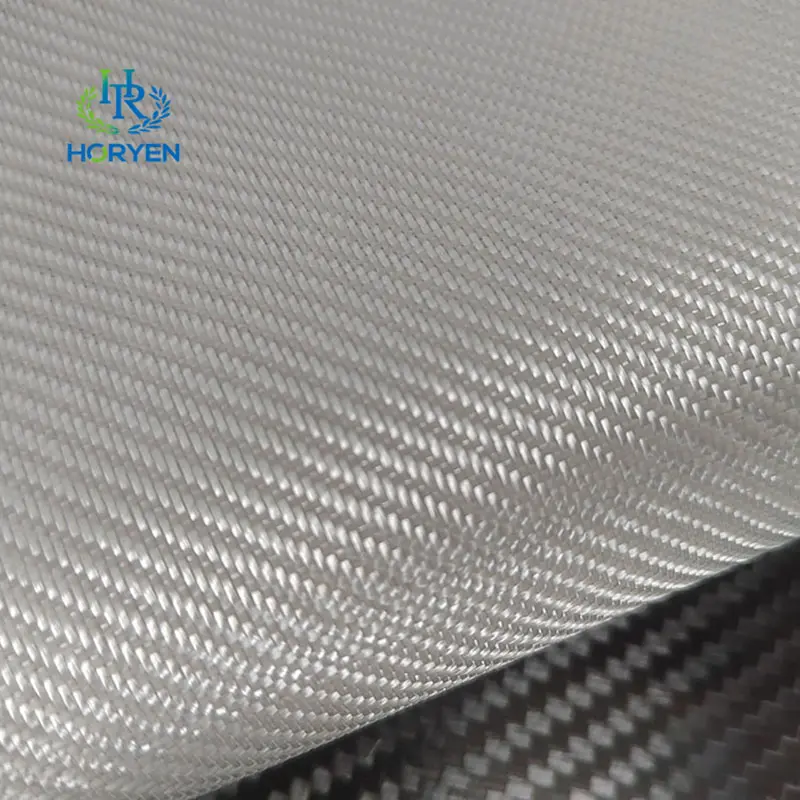

High strength and lightweight: Unidirectional prepreg carbon fiber cloth has very high strength and lightweight, which can reduce the overall weight of the structure while maintaining high strength.

Superior rigidity: Unidirectional prepreg carbon fiber cloth has strong rigidity and is suitable for applications that require high stiffness.

Anisotropic properties: The mechanical properties of unidirectional carbon fibers are superior in the fiber direction to the vertical direction, which can meet the mechanical performance requirements in specific directions.

Corrosion resistance: Carbon fiber has good resistance to chemicals, making it excellent in harsh environments.

Good fatigue performance: It has excellent fatigue performance and can maintain stable performance under repeated loading.

Design feasibility: By changing the direction and number of fiber layers, composite materials that meet specific mechanical performance requirements can be designed.

|

Product Information |

|

|

Product Type |

UD Prepreg Carbon Fiber Fabric |

|

Material |

Carbon fiber fabric and epoxy resin |

|

Weave style |

UD |

|

FAW |

Customized |

|

Thickness |

Customized |

|

Color |

Black |

|

Width |

100cm |

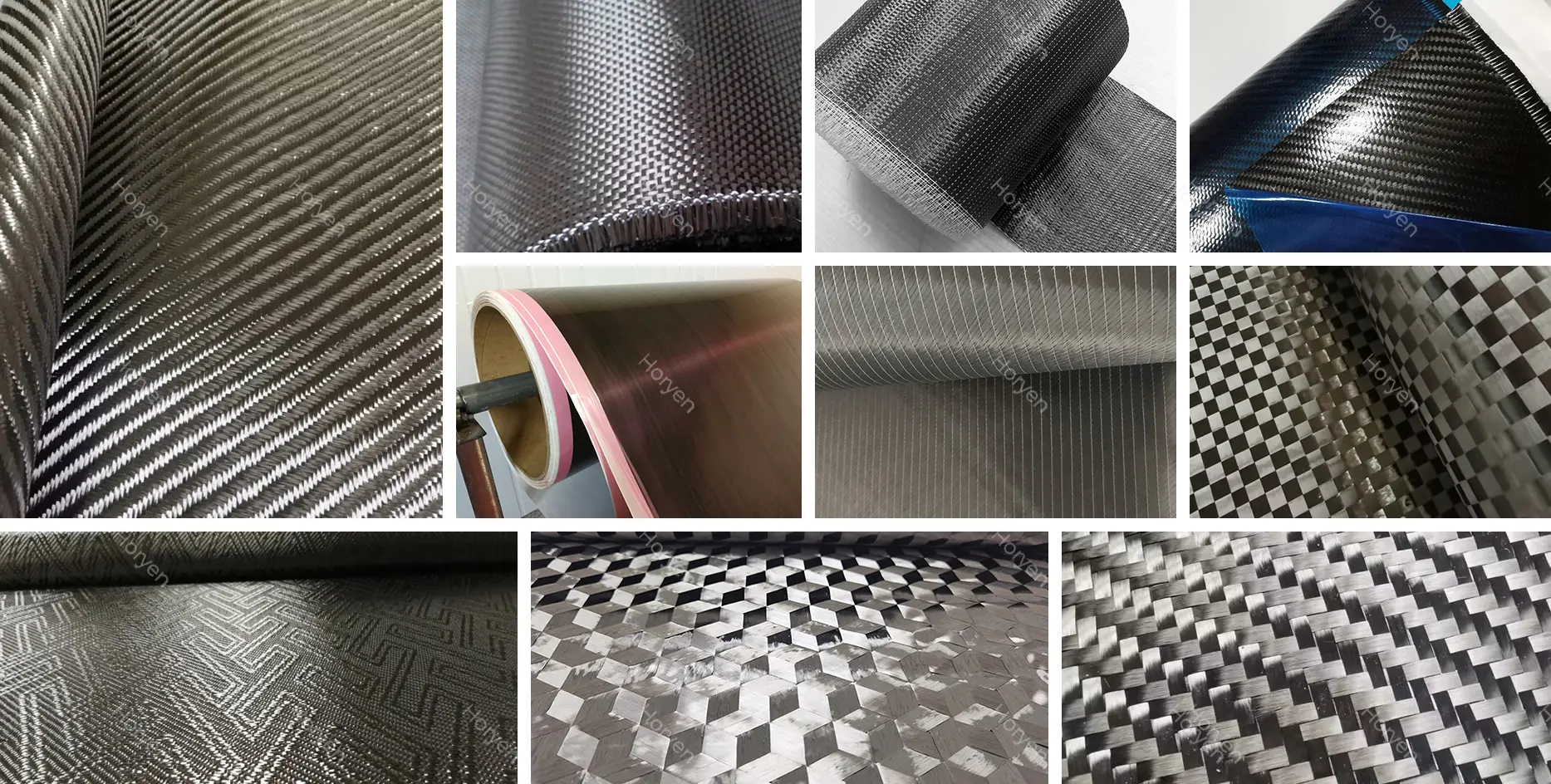

More Choice

Application Field

● Aerospace: Used for structural components such as aircraft, drones, spacecraft, etc., due to its lightweight and high-strength characteristics, it can reduce weight and improve fuel efficiency.

● Automotive manufacturing: Used for the body, chassis, and other components of high-performance racing and luxury cars to improve the overall performance and safety of the vehicle.

● Wind energy: applied in the manufacturing of wind turbine blades to improve the efficiency and service life of wind turbines.

● Sports equipment: such as golf clubs, tennis rackets, skis, etc., to improve the performance of sports equipment.

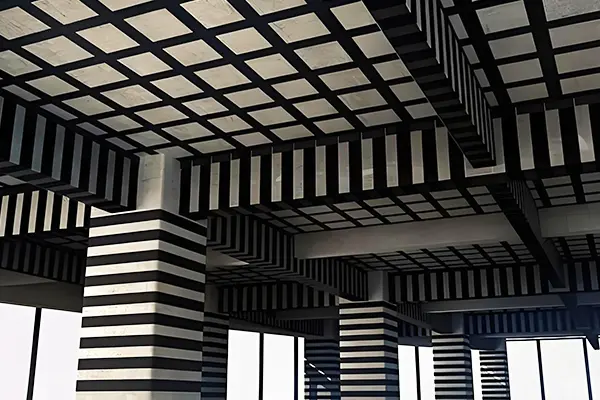

● Architecture and Civil Engineering: Used to reinforce structures, improve the seismic resistance and durability of buildings.

Preparation Process

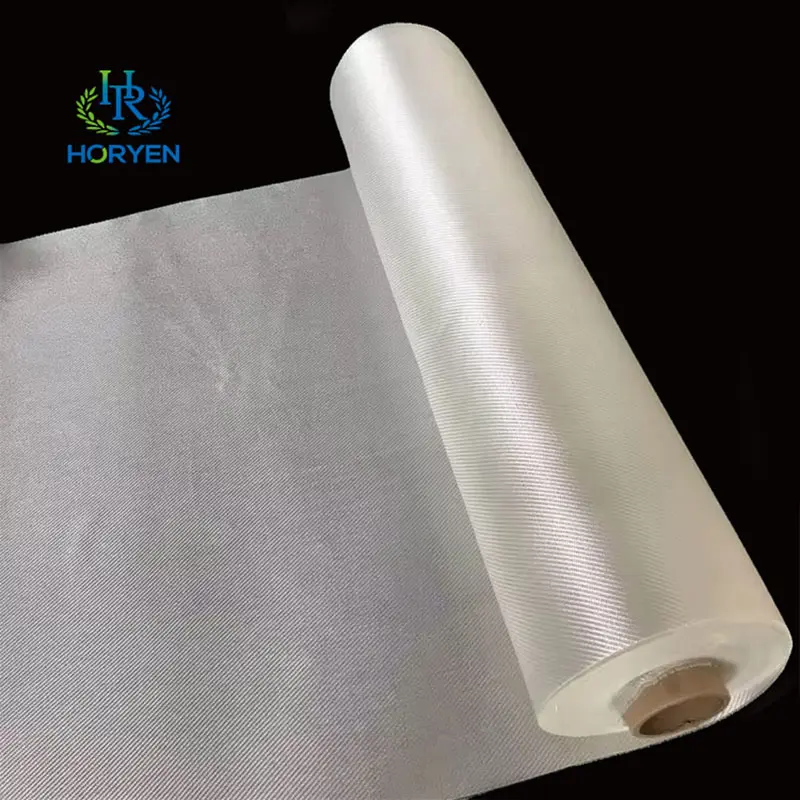

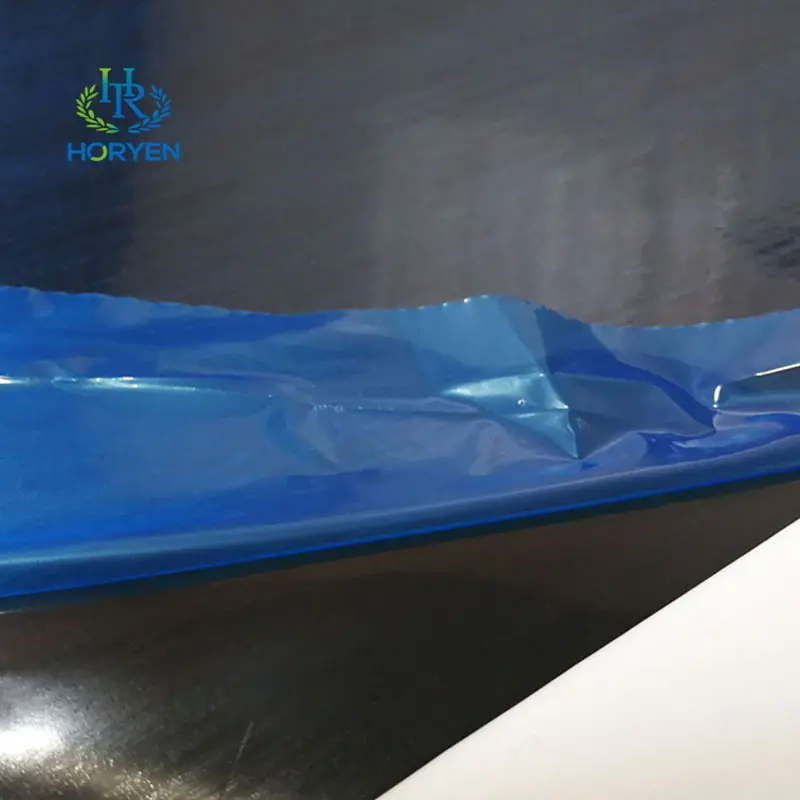

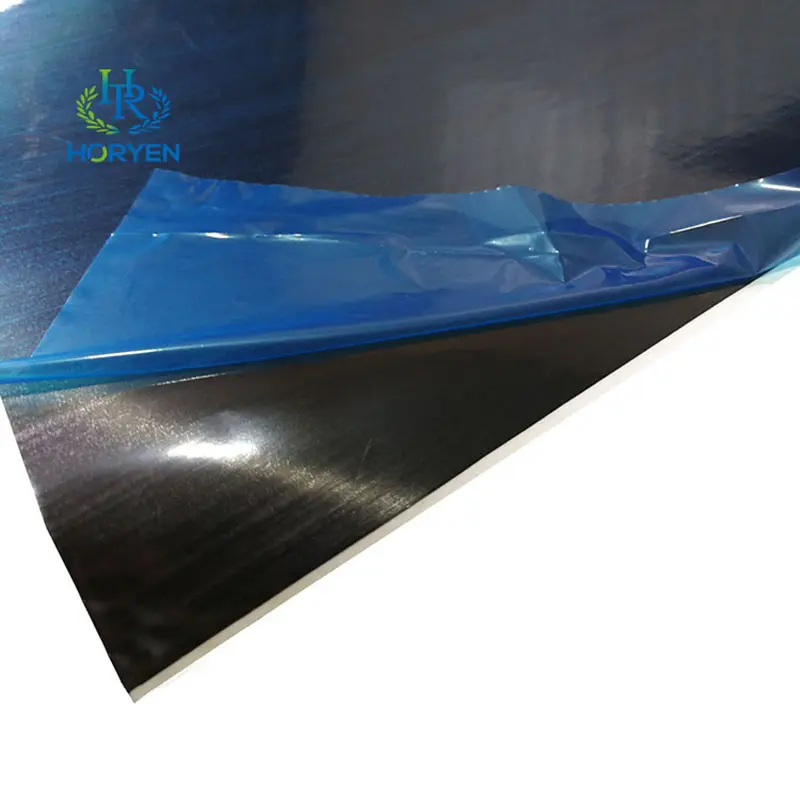

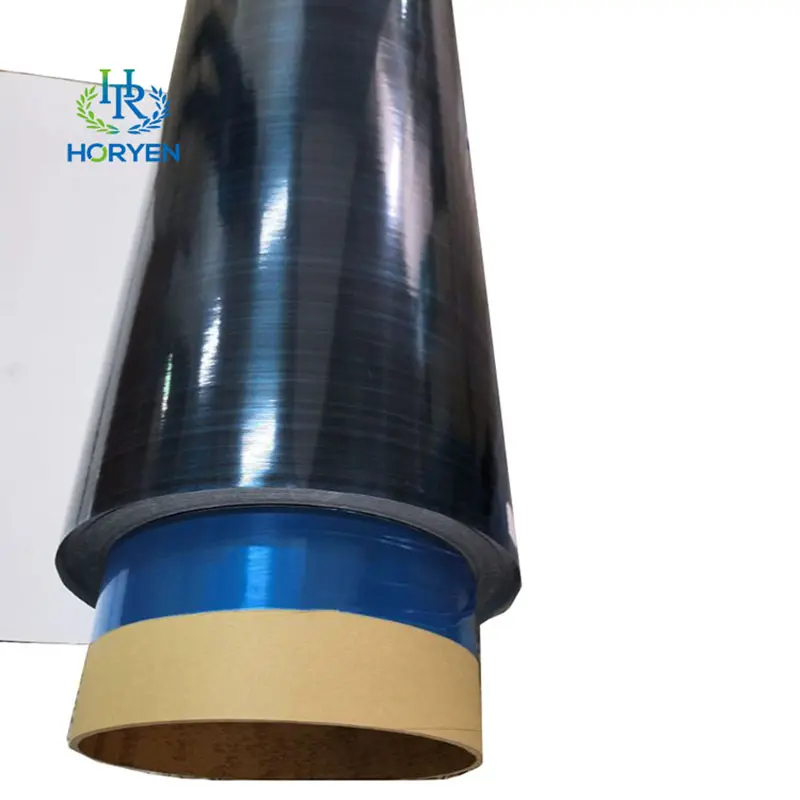

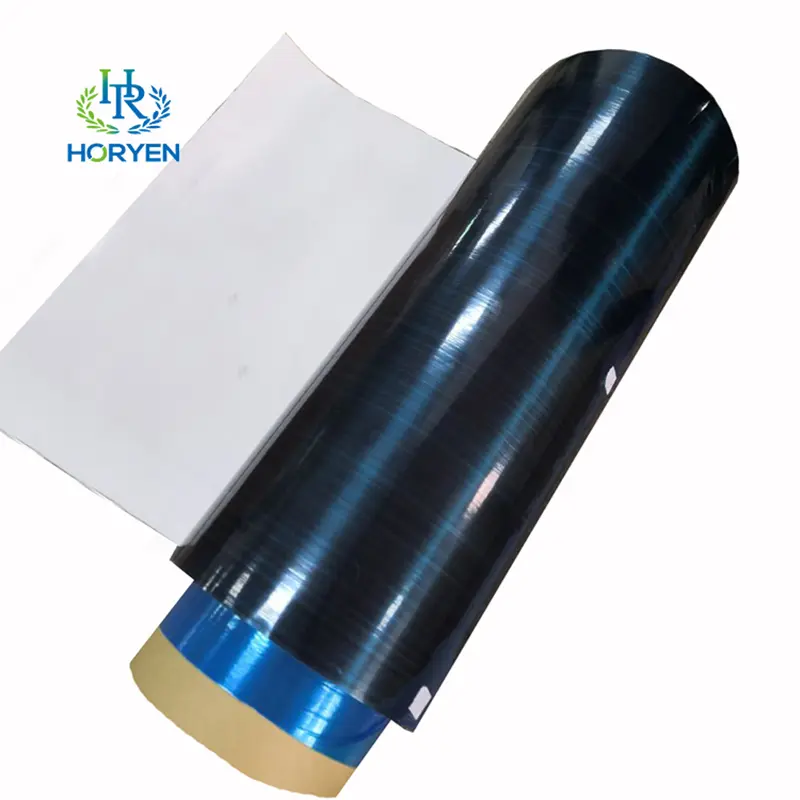

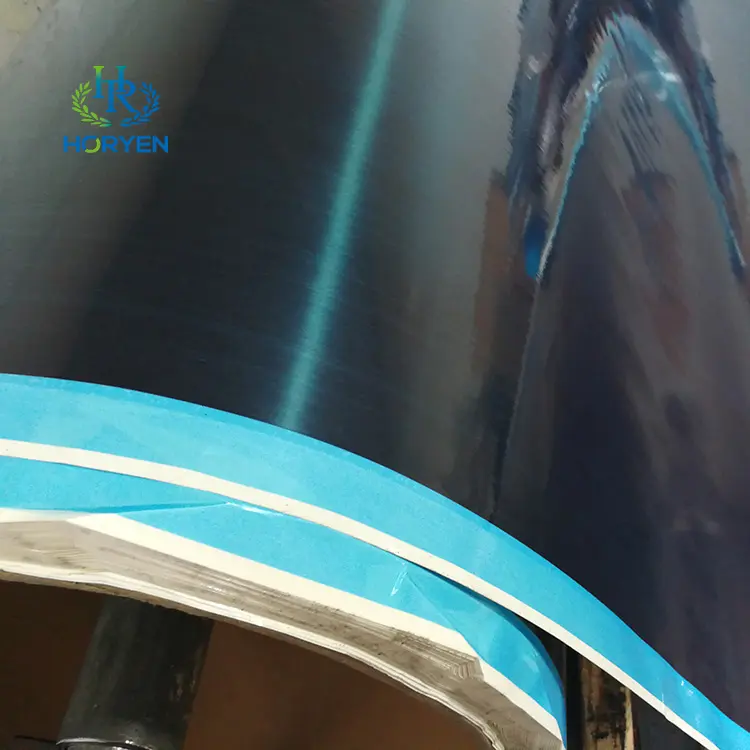

The preparation process of UD carbon fiber prepreg fabric mainly includes steps such as coating, hot pressing, cooling, coating, and winding. Firstly, carbon fiber yarn is mixed with materials such as epoxy resin, and then the mixture is uniformly coated on release paper through coating process. Then, it is subjected to hot pressing and cooling treatment, and finally rolled into a prepreg. The entire process requires strict control of temperature and pressure to ensure the quality and performance of the prepreg.

Why Choose Us?

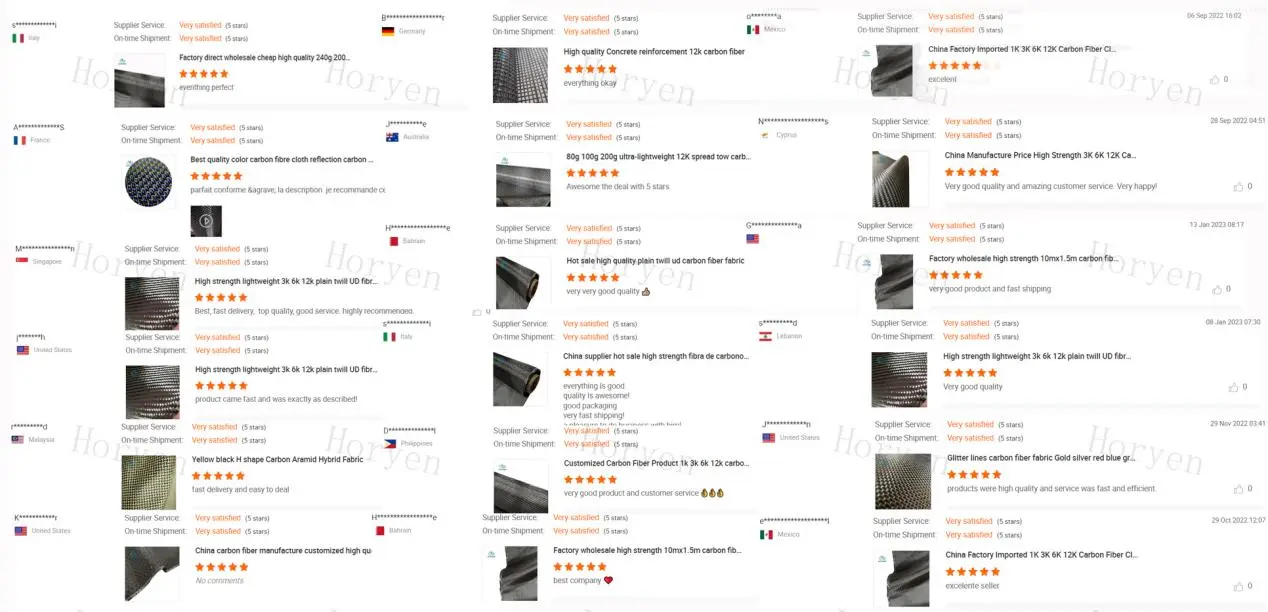

Buyer Review

Our Factory

Packing & Transportation

FAQ

Product Parameter

| Product Information | |||||

| Product Type | Carbon aramid Fiber Fabric | ||||

| Material | Carbon fiber and aramid fiber | ||||

| Fabric Type | Cloth | ||||

| Warp | 3k | ||||

| FAW | 200g/m2 | ||||

| Thickness | 0.25mm | ||||

| Color | Yellow | ||||

| Width | 100cm or customized | ||||