-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

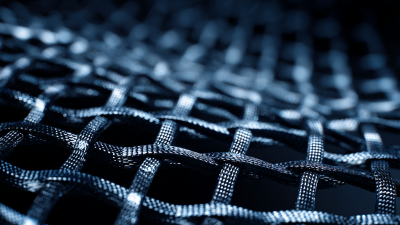

As the aerospace industry continually seeks innovative materials to enhance performance and reduce weight, "Carbon Fiber Tape" has emerged as a game-changer. According to a report by the Global Carbon Fiber Tape Market, the demand for carbon fiber composites in aerospace applications is projected to grow significantly, reaching over USD 1.5 billion by 2025. This growth is driven by the material's unique properties, such as tensile strength, fatigue resistance, and lightweight characteristics, making it ideal for aircraft parts and components. Additionally, studies indicate that the use of carbon fiber tape can lead to a weight reduction of up to 30% compared to traditional materials, translating into improved fuel efficiency and operational performance. As aerospace engineers increasingly leverage carbon fiber tape for various applications, understanding its advantages becomes essential in driving innovation and ensuring safety and efficiency in modern aviation.

Carbon fiber tape has emerged as a game-changer in aerospace engineering, offering a plethora of advantages that significantly enhance performance and efficiency. One of the most compelling benefits is its exceptional strength-to-weight ratio, which is about five times stronger than steel while being significantly lighter. According to a report by the Aerospace Industries Association, the use of carbon fiber composites can lead to weight reductions of up to 30% in aircraft structures, translating into improved fuel efficiency and reduced operating costs.

Additionally, carbon fiber tape exhibits remarkable resistance to fatigue and corrosion, which is critical in the harsh environments experienced during flight. A study conducted by the National Institute of Aerospace highlights that aircraft using carbon fiber components have a lifespan that can be 50% longer than those made with traditional materials. This durability not only enhances safety but also minimizes maintenance needs, allowing for more cost-effective operations over an aircraft's lifetime. The integration of carbon fiber tape into aerospace applications is rapidly transforming industry standards, underscoring the material's pivotal role in the future of aviation.

Carbon fiber tape has emerged as a game-changer in aerospace engineering, particularly due to its enhanced strength-to-weight ratio. This material offers significant advantages over traditional materials, allowing engineers to design aircraft that are both lighter and more robust. The lightweight nature of carbon fiber tape contributes to improved fuel efficiency and overall performance, which is increasingly critical in an industry where every ounce matters. As aircraft become more reliant on advanced materials to meet stringent regulations and performance expectations, carbon fiber tape plays a crucial role in delivering the necessary structural integrity without adding excessive weight.

In the automotive sector, the push for electric vehicles and adherence to stringent emission regulations further accentuate the benefits of using carbon fiber tape. The automotive industry is experiencing a paradigm shift towards lightweight vehicles as manufacturers seek to enhance energy efficiency and reduce carbon footprints. By integrating carbon fiber tape into various components, vehicles can achieve a superior strength-to-weight ratio, which is vital for improving acceleration, handling, and overall driving experience. As the market for carbon fiber composites continues to grow, driven by advancements in manufacturing techniques and increasing awareness of sustainability, the role of carbon fiber tape in both aerospace and automotive applications will undoubtedly expand, unlocking new possibilities for innovation and efficiency.

Carbon fiber tape has emerged as a game-changer in aerospace engineering, playing a crucial role in enhancing performance through its unique characteristics of durability and resistance. According to a report by the Markets and Markets research group, the aerospace carbon fiber market is projected to reach $5.2 billion by 2025, highlighting the growing dependence on these materials for high-performance applications. The lightweight yet robust nature of carbon fiber tape contributes significantly to weight reduction in aircraft, which translates to improved fuel efficiency and lower operational costs.

The superior resistance properties of carbon fiber tape also make it an ideal choice for aerospace applications, where exposure to extreme conditions is a norm. It exhibits exceptional tensile strength, with a strength-to-weight ratio five times that of steel, which is vital for structural components that must withstand high stresses. Furthermore, its resistance to corrosion and fatigue ensures longevity, reducing maintenance needs and enhancing aircraft reliability. According to the National Aeronautics and Space Administration (NASA), using carbon fiber materials can lead to a weight reduction of up to 30% in aircraft structures, underscoring its pivotal role in advancing aerospace technology.

Carbon fiber tape has emerged as a game-changer in the aerospace engineering sector, particularly when it comes to cost-effectiveness compared to traditional materials. As the industry constantly seeks ways to enhance performance while minimizing expenses, carbon fiber tape offers a unique balance of lightweight strength and durability. Unlike conventional materials such as aluminum or steel, carbon fiber tape significantly reduces the overall weight of aerospace components, leading to lower fuel consumption and increased efficiency in flight operations. This advantage is not just in performance but also translates into substantial long-term savings.

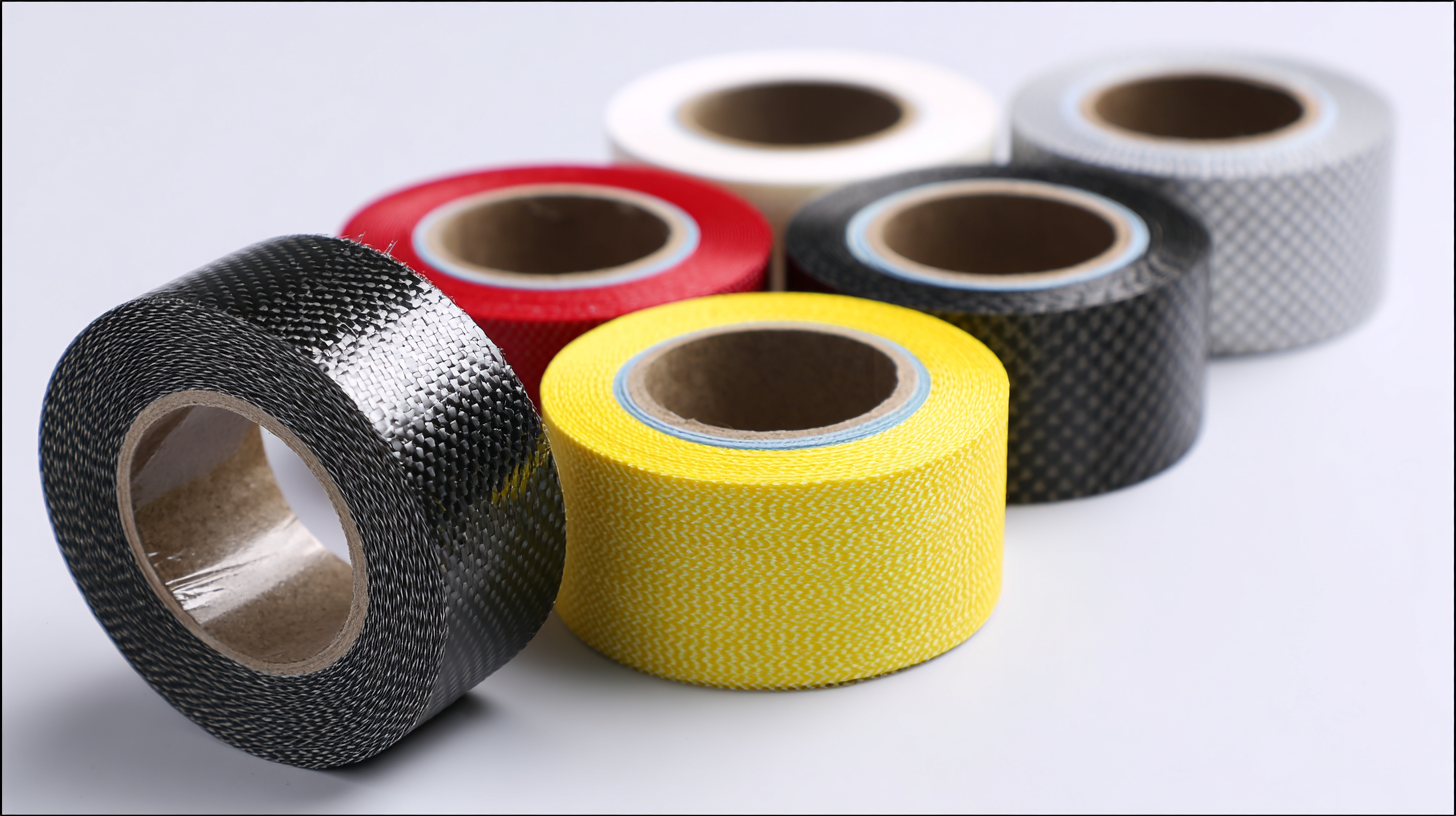

Moreover, the manufacturing process of carbon fiber tape is more streamlined and requires fewer materials, which contributes to reduced production costs. The tape is easier to handle and can be applied in various shapes and configurations, allowing engineers to minimize waste and optimize the use of resources. This adaptability means it can be tailored to specific applications in aerospace, reducing the need for multiple materials and complex assembly processes. As a result, aerospace companies are increasingly turning to carbon fiber tape not only for its performance benefits but also as a financially sound alternative to traditional construction materials.

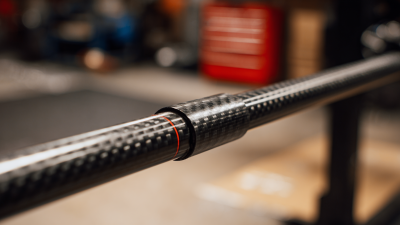

Carbon fiber tape is revolutionizing modern aircraft design with its incredible strength-to-weight ratio and versatility. Aerospace engineers are increasingly turning to this advanced material to optimize the structural integrity of aircraft components while significantly reducing overall weight. Its application extends to various parts of an aircraft, including wings, fuselage, and even interior elements, where weight reduction directly translates to fuel efficiency and better performance.

When considering carbon fiber tape for aircraft design, it is essential to follow a few tips for optimal results. First, ensure that you choose the right type of tape that suits the specific demands of your project, as different weaves and resin systems offer varying benefits. Second, pay attention to proper surface preparation and application techniques, as this will enhance adhesion and structural performance. Lastly, regular testing should be conducted to evaluate the integrity of carbon fiber-reinforced components, ensuring they meet safety regulations and performance standards.

Innovative uses of carbon fiber tape are not limited to structural applications; it is also finding its place in the aesthetics of aircraft interiors. Designers are using carbon fiber elements to create stylish yet functional spaces that maintain the lightweight benefits of the material. As the aerospace industry continues to evolve, carbon fiber tape is poised to remain at the forefront of innovative aircraft design.