-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

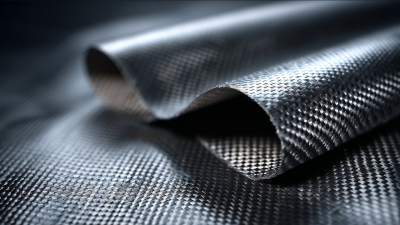

The introduction of aramid fabric into the aerospace and automotive industries marks a significant evolution in material science, driven by the need for lightweight, durable, and high-performance solutions. According to a market research report by Grand View Research, the global aramid fiber market size was valued at approximately $4.41 billion in 2020 and is expected to exhibit a compound annual growth rate (CAGR) of 9.4% from 2021 to 2028. This growth underscores the increasing adoption of aramid fabric in applications where strength and thermal stability are paramount.

Aramid fabric's unique properties—such as superior tensile strength, resistance to heat and chemicals, and lightweight characteristics—make it an ideal choice for aerospace components and automotive parts. The National Research Council reports that materials like aramid fabric can reduce aircraft weight by up to 30%, contributing to fuel efficiency and lower emissions, which is critical in an era where sustainability is at the forefront of industry innovation.

As we explore the top 10 applications of aramid fabric in these sectors, we will uncover how this remarkable material is not only enhancing performance but also shaping the future of transportation technology. From improved safety in automotive design to advanced aerospace engineering, aramid fabric consistently proves to be a game-changing influence across these dynamic industries.

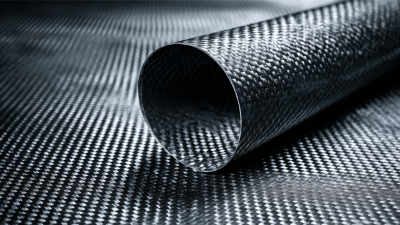

Aramid fabric, renowned for its exceptional strength and heat resistance, is revolutionizing the aerospace and automotive sectors. With properties that significantly outperform traditional materials, aramid is becoming a go-to choice for manufacturers aiming to enhance the durability and safety of their products. Its lightweight nature allows for improved fuel efficiency, while its high tensile strength enables the creation of components that withstand extreme conditions, making it a critical material in the design of aircraft and vehicles.

When considering aramid fabric for your designs, remember its unique properties can be leveraged in various ways. Tip: Use aramid composites in high-stress applications, such as aircraft fuselages or automotive frames, to take advantage of their low weight and high impact resistance. Additionally, consider layering aramid with other materials for enhanced performance, as this combination can lead to innovative solutions tailored to specific aerospace requirements.

Furthermore, the thermal stability of aramid fabric makes it suitable for applications involving high temperatures, such as engine components and heat shields. Tip: Implement aramid fabric in parts that require fire resistance to ensure safety and compliance with aviation standards. By integrating this advanced material into your design processes, you can push the boundaries of innovation and performance in aerospace engineering.

Aramid fabric, known for its exceptional strength-to-weight ratio and thermal resistance, is increasingly being adopted in the automotive industry. According to a report by MarketsandMarkets, the global aramid fiber market is projected to reach approximately $4.33 billion by 2026, growing at a CAGR of around 6.8%. This surge is attributed to the rising demand for lightweight materials that enhance fuel efficiency and performance in vehicles. Manufacturers are incorporating aramid fibers in various applications, including tire reinforcement, brake pads, and body panels, leading to significant advancements in automotive safety and durability.

Innovative applications of aramid fabric are particularly evident in the development of electric and hybrid vehicles, where weight reduction is crucial for enhancing battery efficiency. A study by the European Commission indicated that using lightweight materials like aramid can reduce vehicle weight by up to 20%, which directly translates to improved energy consumption. Additionally, aramid's inherent flame-retardant properties are proving beneficial in protective gear for automotive workers and interior components, ensuring safety without compromising on design or comfort. With the automotive sector continually evolving, the integration of aramid fabrics represents a transformative step towards sustainability and enhanced vehicle performance.

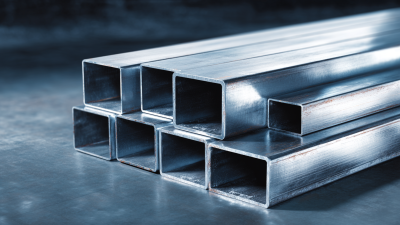

Aramid fabric has increasingly become a pivotal material in aerospace and automotive innovations, standing out when compared to traditional materials like aluminum and steel. The unique properties of aramid fibers, such as high tensile strength, lightweight nature, and resistance to heat and chemicals, provide significant advantages. For instance, aramid fabric's exceptional impact resistance improves safety in aerospace applications, while its lightweight characteristic enhances fuel efficiency in automotive designs. Traditional materials, while reliable, often add unnecessary weight that reduces performance and increases energy consumption.

Tips: When considering materials for aerospace projects, prioritize materials that offer both strength and weight advantages. This not only contributes to enhanced safety but can also lead to operational cost savings in the long run.

Moreover, in a comparative analysis, aramid fabrics demonstrate superior durability under extreme conditions compared to traditional options. They are less prone to corrosion and fatigue, leading to longer life cycles for components. This longevity reduces maintenance costs and downtime, a crucial factor in the aerospace industry where reliability is paramount. Shifting from traditional materials to aramid can indeed revolutionize the design and functionality of aircraft and vehicles alike.

Tips: Evaluate the lifecycle costs of aramid fabric versus traditional materials to understand the long-term economic benefits, particularly in high-performance applications.

The increasing demand for sustainable materials in aerospace and automotive industries has led to the rising popularity of aramid fabric. This advanced synthetic fiber not only offers superior strength and lightweight properties but also aligns with the industry's shift towards eco-friendly practices. As manufacturers seek to reduce their carbon footprint, aramid products are being developed through more sustainable processes, from sourcing raw materials to production.

Tips: When considering aramid fabric for your next project, look for manufacturers who prioritize recycled materials and sustainable practices. This can lead not only to environmental benefits but also to cost savings in the long run.

Another significant trend is the advancement in manufacturing techniques, such as 3D printing and automated processes, which are enhancing the efficiency of aramid fabric production. These innovations will enable companies to create more complex designs while minimizing waste. As technology progresses, we can expect further integration of smart fabrics that incorporate sensors and other digital elements, making aramid materials an even more compelling choice for future applications.

Tips: Stay informed about emerging technologies in aramid manufacturing; utilizing these innovations can give your products a competitive edge while contributing to sustainability efforts.

| Application Area | Key Benefits | Future Trends | Sustainability Efforts |

|---|---|---|---|

| Aerospace | High strength-to-weight ratio | Increased use of lightweight materials | Bio-based aramid fibers |

| Automotive | Enhanced durability and impact resistance | Integration with electric vehicle technologies | Recycling of aramid materials |

| Protective Gear | Lightweight yet highly protective | Smart textiles integration | Sourcing from renewable resources |

| Textiles | Abrasion resistance and longevity | Customization for specific applications | Closed-loop manufacturing processes |

Aramid fabric, known for its exceptional strength and durability, has become a cornerstone in both the aerospace and automotive sectors. In aerospace applications, leading companies like Boeing have successfully integrated aramid composites into their aircraft designs. For instance, the use of aramid in the production of lightweight yet robust aircraft components significantly reduces fuel consumption while enhancing performance. The incorporation of this material not only meets stringent safety standards but also contributes to the overall sustainability goals of the industry.

In the automotive realm, manufacturers such as BMW are harnessing the benefits of aramid fabric in their high-performance vehicles. The strategic use of aramid in tire reinforcement and body panels has optimized weight efficiency while maintaining high structural integrity. Case studies reveal that vehicles utilizing aramid composites show improved crashworthiness, offering enhanced safety for passengers. Moreover, the innovative use of aramid is paving the way for electric vehicles, ensuring they meet the demands of increased battery efficiency and range without compromising safety or performance. These successful implementations underline the transformative impact of aramid fabric in modern engineering.