-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Aramid fabric, a high-performance material, is becoming increasingly essential in various industries due to its remarkable properties. According to a recent report by MarketsandMarkets, the global aramid fiber market is projected to reach USD 5.10 billion by 2025, growing at a CAGR of 5.3%. This growth is attributed to the rising demand for lightweight, heat-resistant, and durable materials in sectors such as automotive, aerospace, and personal protective equipment.

Expert in the field, Dr. Jonathan Reed, highlights the importance of aramid fabric by stating, "The unique properties of aramid fibers contribute significantly to the performance of modern composites, making them indispensable in safety and high-stress applications." With its exceptional resistance to abrasion and extreme temperatures, aramid fabric finds applications ranging from bulletproof vests to reinforcing components in aircraft structures.

As industries evolve and the need for advanced materials increases, understanding the characteristics and uses of aramid fabric becomes crucial. This article will delve into the properties, manufacturing processes, and diverse applications of aramid fabric, providing insights into its vital role in enhancing safety and efficiency across multiple sectors.

Aramid fabric is a synthetic fiber noted for its high strength-to-weight ratio and exceptional resistance to heat and wear. This advanced material, primarily composed of aromatic polyamide, is engineered to deliver exceptional durability, making it a preferred choice in various industries. According to industry reports, the global aramid fiber market was valued at approximately $5 billion in 2020, with projections indicating a robust growth rate as demand surges in sectors such as aerospace, automotive, and protective clothing.

The unique composition of aramid fabric grants it outstanding properties, including resistance to flames, chemicals, and abrasion. Its lightweight nature, combined with high tensile strength, makes it ideal for applications ranging from military uniforms to high-performance sports gear. Notably, aramid fibers can withstand temperatures exceeding 200 degrees Celsius, a trait that positions them as a critical material in heat-resistant applications. With its increasing adoption in consumer electronics accessories, aramid fabric is becoming synonymous with stylish yet functional protection for devices, ensuring that modern technology can be both safeguarded and aesthetically pleasing.

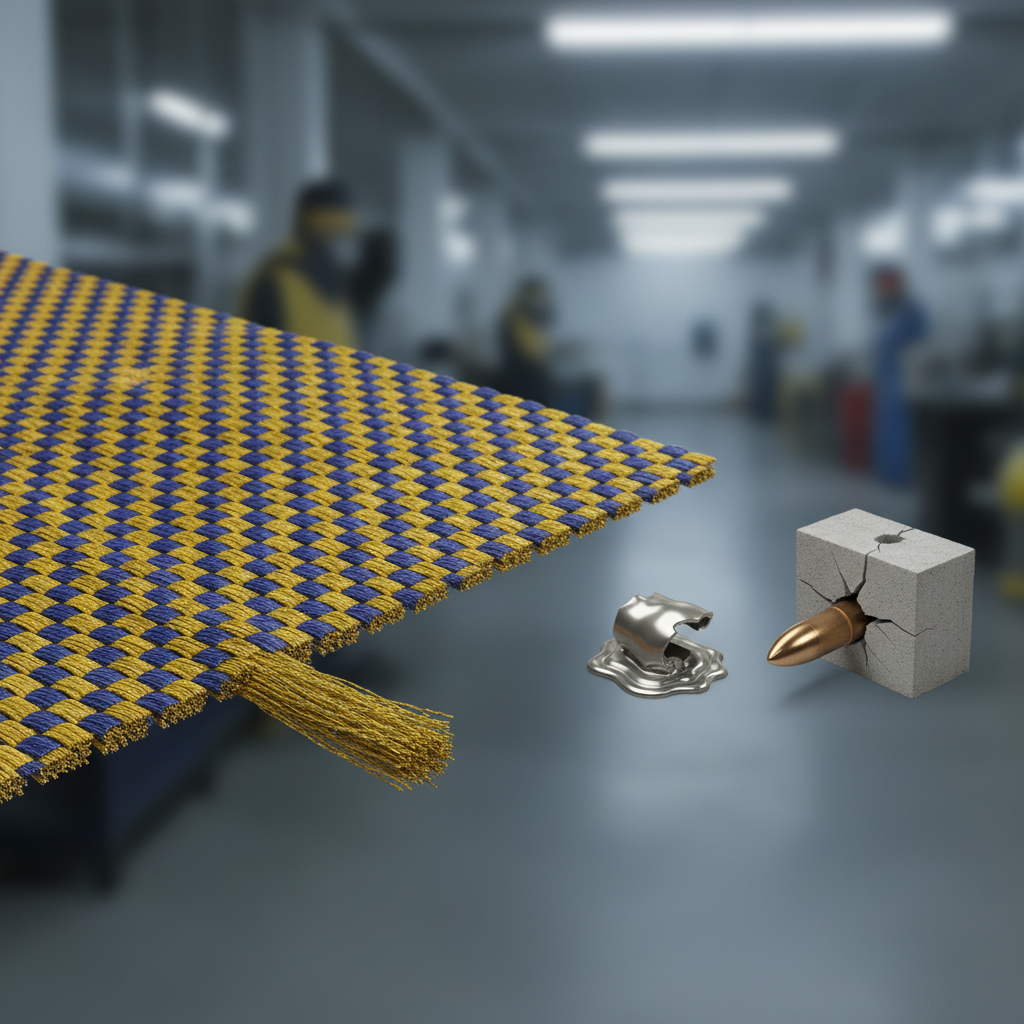

Aramid fabric, renowned for its remarkable properties, stands out in various industrial applications due to its exceptional strength and durability. Notably, aramid fibers, such as Kevlar and Nomex, exhibit tensile strengths that can reach up to 5 times that of steel while being significantly lighter. According to a report by the Technical Textile Markets, aramid fabric strength is approximately 3000 MPa, making it a top choice for protective apparel and aerospace components. The fabric's ability to withstand extreme conditions facilitates its use in environments where safety and performance are critical.

In addition to its impressive strength, aramid fabric demonstrates superior resistance to heat and flames. For instance, Nomex is widely utilized in firefighting gear due to its capability to withstand temperatures exceeding 370°C (700°F) without compromising its integrity. The International Fiber Journal highlights that the global aramid fiber market is expected to grow by 5.5% annually, driven largely by the textile's durability and resistance properties. This growth reflects the increasing demand for enhanced protective gear in industries from military applications to personal protective equipment, showcasing aramid fabric's vital role in advancing safety standards.

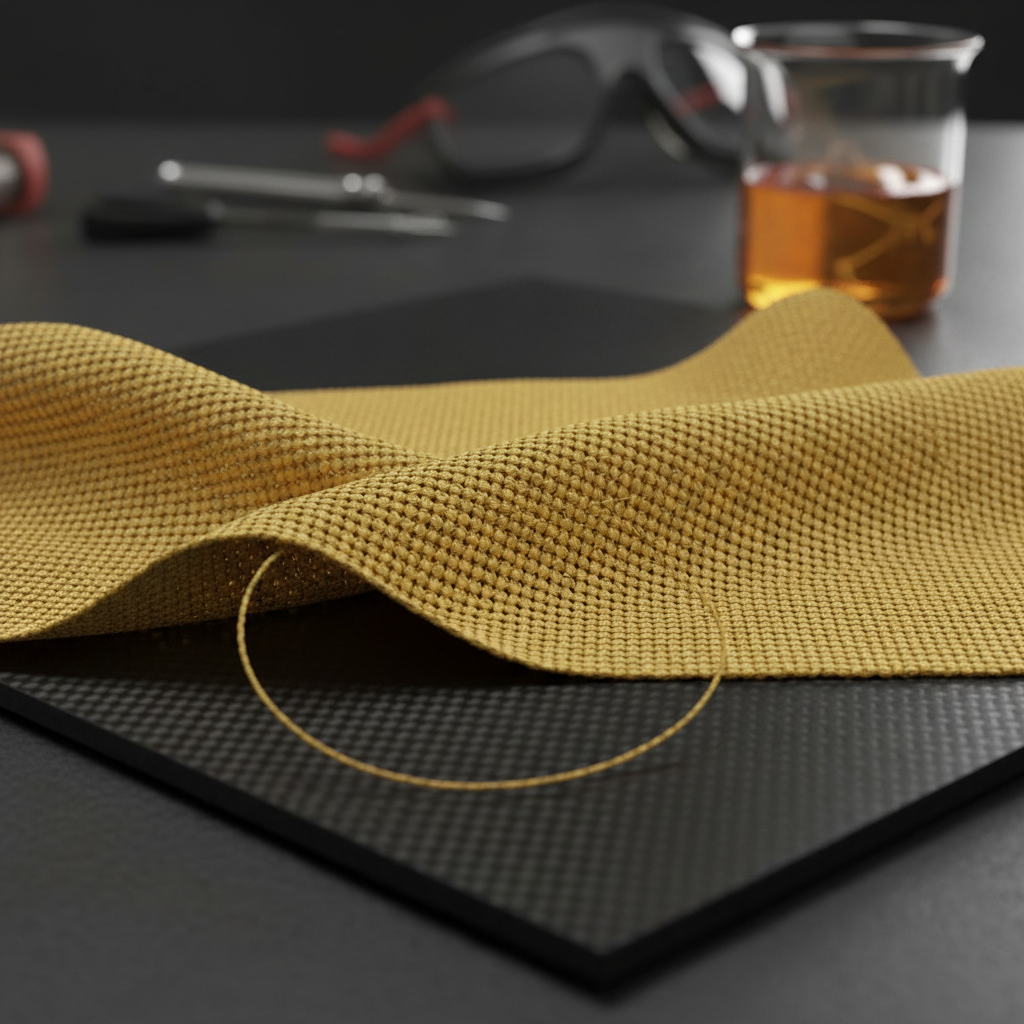

Aramid fabric, known for its exceptional strength and resistance to heat, plays a pivotal role in the aerospace and automotive industries. According to a report by MarketsandMarkets, the global aramid fiber market is expected to reach $5.25 billion by 2025, with aerospace and automotive applications being significant contributors to this growth. The lightweight yet durable nature of aramid fibers makes them ideal for use in aircraft components, such as fuselage structures and interior parts, where reducing weight without compromising safety is crucial.

In the automotive sector, aramid fabric is increasingly utilized in high-performance tires and brake systems. A study published by Grand View Research highlights that the automotive segment is projected to grow at a CAGR of over 6% from 2021 to 2028, driven by the demand for enhanced safety measures and fuel efficiency. Furthermore, aramid's unique thermal stability allows it to withstand extreme conditions, making it an essential material for electric vehicles, which frequently experience high thermal loads. With ongoing advancements in aramid technology, its applications in these industries are set to expand, reinforcing its significance as a material of choice for innovative engineering solutions.

| Property | Details | Applications |

|---|---|---|

| High Strength | Aramid fabrics are known for their exceptional strength-to-weight ratio, making them suitable for load-bearing applications. | Aerospace structural components, automotive body armor. |

| Heat Resistance | Can withstand high temperatures without degrading, ideal for high-heat environments. | Brake pads, thermal insulation in aerospace applications. |

| Chemical Resistance | Resistant to a wide range of chemicals, ensuring long-term durability. | Protective clothing, electrical insulation. |

| Lightweight | Significantly lighter than traditional materials while maintaining superior strength. | Aerospace fuselages, automotive components for weight reduction. |

| Impact Resistance | Excellent impact resistance, protecting against breakage or deformation. | Helmets, ballistic vests, composite materials in automotive. |

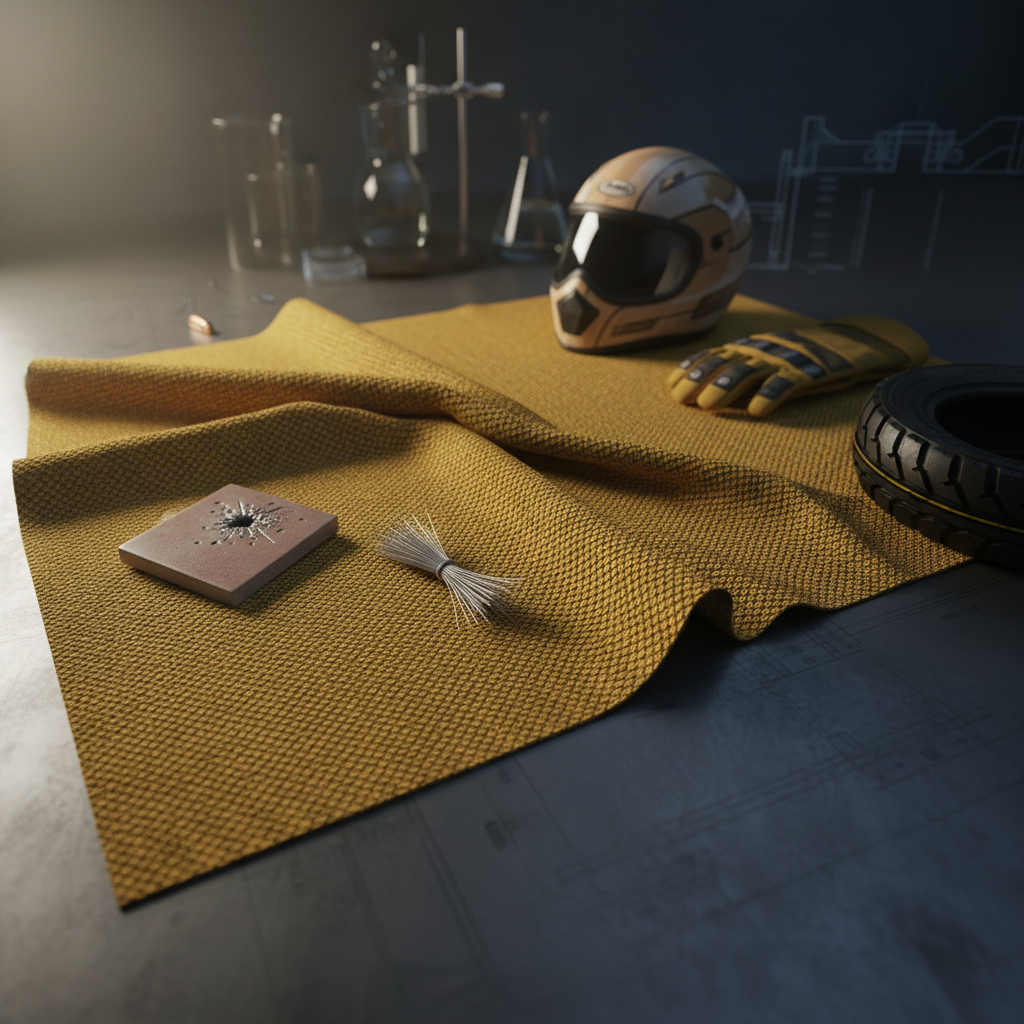

Aramid fabric, known for its exceptional strength and heat resistance, plays a crucial role in the development of personal protective equipment (PPE) and gear. This synthetic fiber, commonly found in products like Kevlar and Twaron, is designed to withstand high temperatures, abrasions, and impacts, making it an ideal choice for protective clothing and gear used by firefighters, law enforcement, and industrial workers. The unique molecular structure of aramid fibers increases their durability, providing wearers with enhanced safety in hazardous environments.

In addition to its protective qualities, aramid fabric is lightweight and flexible, allowing for ease of movement without compromising on safety. This is particularly important in applications such as tactical vests and helmets, where both comfort and protection are paramount. Furthermore, the fabric's resistance to chemicals and water adds an extra layer of safety, making it suitable for a wide range of environments, from military operations to emergency rescue missions. Overall, aramid fabric is an indispensable material in the realm of personal protective equipment, ensuring that individuals remain safe and efficient in potentially dangerous situations.

This bar chart illustrates the properties of Aramid Fabric, showcasing its impressive strength, resistance to abrasion and heat, as well as its chemical resistance. These attributes are crucial for its use in personal protective equipment and gear.

The evolution of aramid fabric technologies has been remarkable, and the future holds even greater promise. Innovations in production methods are enhancing the durability, heat resistance, and overall performance of aramid fibers. Companies are now exploring the integration of nanotechnology to improve the strength-to-weight ratio of aramid fabrics, potentially expanding their use in aerospace and automotive industries. Moreover, advancements in recycling methods aim to make aramid fabric production more sustainable, responding to increasing environmental concerns.

Tips: Consider choosing aramid fabric products that highlight eco-friendly manufacturing practices. This not only contributes to sustainability efforts but may also provide high-performance options that meet complex industry demands.

In addition to industrial applications, aramid fabrics are being incorporated into everyday products, such as protective clothing and sports gear, as manufacturers strive to make them more user-friendly and accessible. As research continues, aramid technology may lead to lighter and more adaptable fabrics, creating new applications in various fields, including smart textiles that can monitor health metrics or environmental conditions.

Tips: When selecting aramid fabric items, look for features that enhance comfort and breathability, as these factors are becoming increasingly important in user-oriented designs.