-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

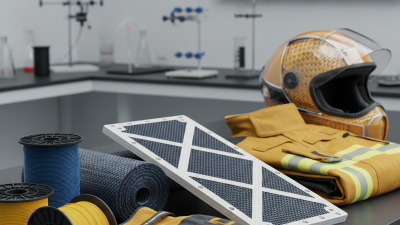

Aramid fiber products have revolutionized a multitude of industries thanks to their unique properties and exceptional performance. Derived from synthetic fibers, aramid materials, such as Kevlar and Nomex, are renowned for their high strength-to-weight ratio, outstanding thermal stability, and remarkable resistance to abrasion and chemicals. These attributes make aramid fibers a preferred choice in applications where durability and reliability are paramount, ranging from aerospace and automotive to protective clothing and sports equipment.

In this exploration of aramid fiber products, we’ll delve into the benefits that these advanced materials offer. Their ability to endure extreme conditions, provide safety, and maintain structural integrity under stress sets them apart from conventional fibers. Additionally, we will examine the diverse applications of aramid fiber products, highlighting how they improve performance and safety across various sectors.

From personal protective gear to sophisticated military equipment, the versatility of aramid fibers continues to expand, underscoring their importance in modern material science. Through a detailed understanding of their benefits, uses, and applications, readers will gain valuable insights into why aramid fiber products are at the forefront of innovative solutions in today’s market.

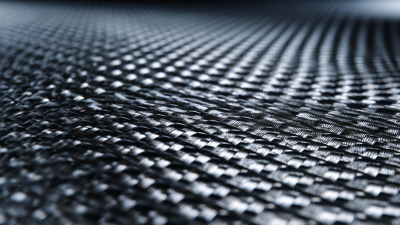

Aramid fibers, known for their exceptional strength and heat resistance, are synthetic fibers widely used in various industries. These fibers are made from a type of polyamide, offering high tensile strength and thermal stability, making them ideal for applications requiring durability and performance. The molecular structure of aramid fibers consists of long chains of repeating units, which contribute to their remarkable properties, including low flammability and resistance to chemicals. Commonly utilized in aerospace, automotive, and military applications, these fibers play a crucial role in enhancing safety and reducing weight in critical components.

**Tips:** When selecting aramid fiber products for specific applications, consider the environment in which they will be used. For instance, in high-temperature settings, ensure the fiber can maintain its integrity. Additionally, pairing aramid fibers with other materials can enhance overall performance, leading to innovative solutions in various engineering challenges.

Moreover, aramid fibers are also popular in personal protective equipment, such as body armor and gloves. Their unique qualities not only provide resistance against cuts and abrasions but also offer essential protection against heat and flames. Industries focusing on safety gear often rely on aramid fibers to ensure that their products meet the highest standards of protection while maintaining comfort and flexibility for the wearer.

Aramid fiber products are increasingly recognized for their numerous benefits across diverse industries, particularly in sectors that demand robust and high-performance materials. According to the Global Aramid Fiber Market Size report, the market is projected to grow from $5.01 billion in 2025 to $10.21 billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.3%. This growth is driven by the fibers' exceptional strength, lightweight properties, and resistance to heat and chemicals, making them ideal for applications in aerospace, automotive, military, and industrial sectors.

The advantages of aramid fibers extend beyond their mechanical properties. They contribute significantly to safety and efficiency in various applications, such as bulletproof vests, fire-resistant clothing, and insulation materials. The high-performance fibers market as a whole is projected to expand from $18.6 billion in 2025 to $40.2 billion by 2035, highlighting a growing inclination toward materials that enhance performance while reducing weight. This trend underscores the vital role aramid fiber products play in advancing innovation and sustainability in industries worldwide.

Aramid fibers, renowned for their exceptional strength and heat resistance, play a crucial role in the production of protective clothing and equipment. These synthetic fibers, often found in garments designed for firefighters, military personnel, and industrial workers, offer high levels of protection without sacrificing comfort. With their lightweight yet durable properties, aramid fibers provide an essential layer of defense against heat, flames, and even abrasions, making them ideal for environments where safety is paramount.

Beyond conventional protective clothing, aramid fibers are increasingly utilized in specialized applications such as ballistic vests and helmets. Their remarkable tensile strength allows for the effective absorption of impact forces, ensuring the safety of personnel in high-stakes situations. Additionally, aramid fibers are integrated into gloves and aprons used in manufacturing and construction, protecting workers from sharp objects and hazardous materials. The versatility and reliability of aramid fibers continue to enhance the effectiveness of protective gear, addressing the evolving demands of various industries while prioritizing user safety.

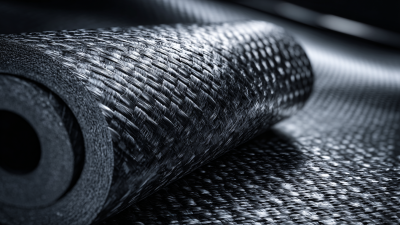

Aramid fiber composites have demonstrated significant advantages in the aerospace and automotive sectors due to their superior strength-to-weight ratio, thermal stability, and resistance to chemical and environmental degradation. In aerospace applications, for instance, using aramid fibers can reduce the weight of aircraft components by up to 30%, enabling greater fuel efficiency and enhanced performance. According to a report by Markets and Markets, the aerospace composite market is expected to reach $37.7 billion by 2025, with aramid fibers playing a crucial role in this growth.

In the automotive industry, aramid fibers are increasingly utilized in protective equipment, brake linings, and structural components. Their high impact resistance helps improve vehicle safety, and recent advancements have led to a 20% reduction in weight for certain automotive parts that incorporate aramid composites. This not only boosts fuel efficiency but also contributes to lower emissions. The global automotive composites market is projected to grow at a CAGR of 8.3% through 2026, highlighting the importance of advanced materials like aramid fibers.

Tips: When considering the use of aramid fiber composites in your projects, evaluate the specific mechanical properties needed for your application. Additionally, keep abreast of the latest industry reports to identify emerging trends and technologies that may enhance the performance and cost-effectiveness of aramid fiber products.

In recent years, the aramid fiber market has witnessed significant advancements, and emerging trends suggest a forward momentum that is expected to continue until 2025. According to a report by Grand View Research, the global aramid fiber market size was valued at approximately $4.63 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028. This increase is being driven by the rising demand for lightweight and strong materials across various sectors, including automotive, aerospace, and military applications, which are increasingly adopting aramid fibers for their superior strength-to-weight ratio and thermal stability.

Innovations in aramid fiber production methods are likely to play a pivotal role in shaping the market landscape. Advancements in manufacturing processes, such as the introduction of environmentally friendly production methods and the development of advanced composite materials, are expected to not only enhance the performance of aramid fibers but also reduce production costs. The Fibre Reinforced Composite Market Report projects that by 2025, the integration of nanotechnology into aramid fiber products will facilitate the creation of stronger and more durable materials, thereby broadening their application range and improving their competitiveness against traditional materials. As industries continue to look for sustainable and high-performance solutions, aramid fibers are poised to become increasingly integral in diverse applications spanning numerous domains.