-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

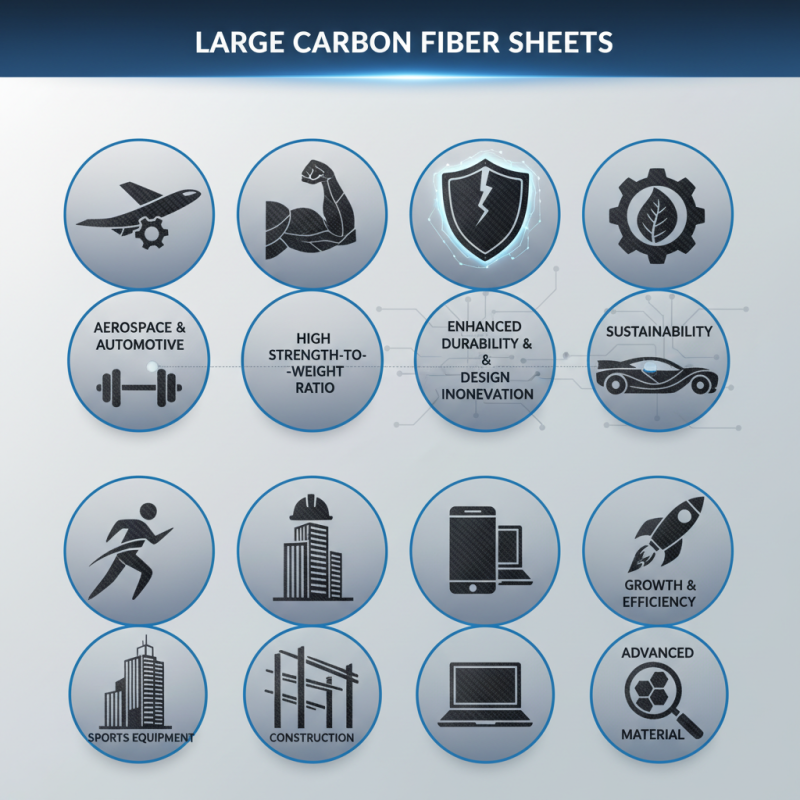

In recent years, the adoption of Large Carbon Fiber Sheets has revolutionized various industries, offering a higher level of performance and efficiency. The unique properties of carbon fiber, including its lightweight nature and impressive strength-to-weight ratio, make it an ideal material for applications ranging from aerospace to automotive engineering. By leveraging Large Carbon Fiber Sheets, manufacturers are not only enhancing the durability and longevity of their products but also driving innovation in designs that were previously unfeasible.

The versatility of Large Carbon Fiber Sheets extends beyond traditional uses, finding applications in sectors such as sports equipment, construction, and even consumer electronics. As industries strive for sustainability and improved functionality, the shift towards materials like carbon fiber becomes a strategic advantage. This article delves into the top ten benefits of utilizing Large Carbon Fiber Sheets, highlighting their transformative impact across different fields and showcasing why they are increasingly becoming a material of choice for engineers and designers alike. Through this exploration, we aim to provide insight into how this advanced material can foster growth and efficiency in various applications.

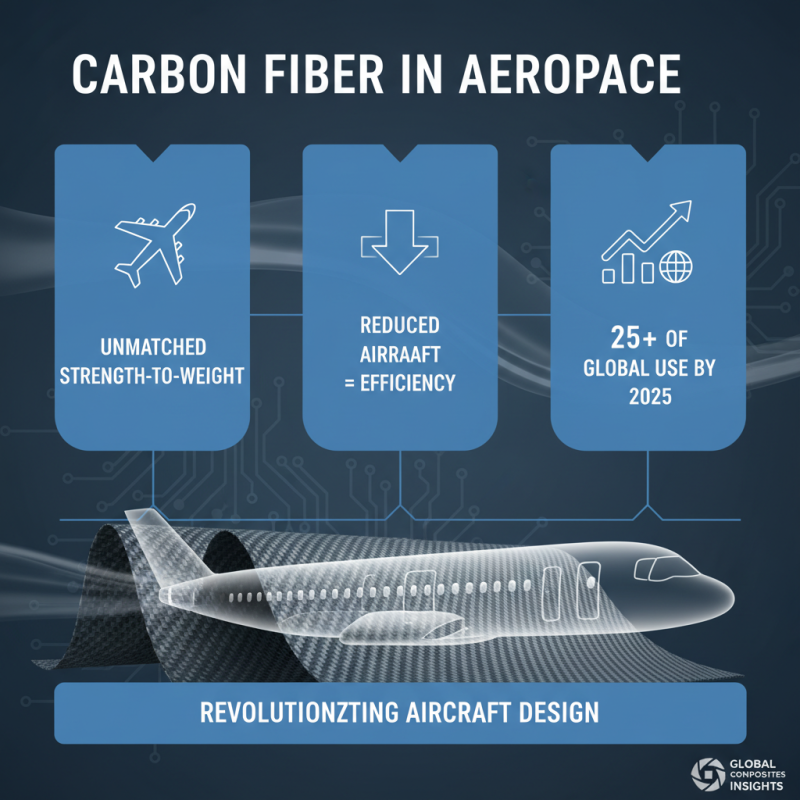

Large carbon fiber sheets have revolutionized the aerospace industry, delivering unmatched performance and efficiency gains. These sheets, known for their remarkable strength-to-weight ratio, provide aircraft manufacturers with the ability to reduce overall weight without compromising structural integrity. According to a report by the Global Carbon Fiber Market, the aerospace sector is forecasted to account for over 25% of carbon fiber usage by 2025, indicating a growing reliance on these advanced composite materials for new aircraft designs.

In aerospace applications, large carbon fiber sheets facilitate enhanced fuel efficiency, which is a critical factor given the rising fuel costs and stringent regulations on emissions. The lightweight properties of carbon fiber result in lighter aircraft, leading to lower operational costs and increased payload capacities. A study from the International Air Transport Association (IATA) showed that the use of composite materials, including carbon fiber, can reduce fuel consumption by up to 20%. This not only benefits airlines economically but also contributes to more sustainable aviation practices by significantly lowering greenhouse gas emissions.

Moreover, large carbon fiber sheets offer excellent resistance to environmental factors such as humidity and corrosion, which are crucial in maintaining aircraft longevity and safety. The ability of these composites to withstand extreme temperatures and pressures enhances their utility in various aerospace components, from fuselage structures to internal frameworks. As advancements in manufacturing techniques continue, the integration of carbon fiber sheets into aerospace applications is set to expand, supporting the industry's drive towards innovation and efficiency.

The automotive industry has been at the forefront of adopting advanced materials to enhance performance and efficiency. One of the standout materials in this evolution is

large carbon fiber sheets, known for their impressive durability and significant weight reduction properties. This innovation allows manufacturers to produce vehicles that are not only lightweight but also possess high structural integrity, translating into improved safety and performance metrics.

Reducing weight is crucial in automotive design as it directly impacts fuel efficiency and handling. By utilizing large carbon fiber sheets, automotive engineers can shave off considerable weight without compromising strength. This weight reduction results in lower emissions and better fuel economy, making vehicles more appealing to environmentally conscious consumers. Additionally, the stiffness and resilience of carbon fiber contribute to enhanced ride quality and handling precision, allowing for a superior driving experience.

With the versatility of carbon fiber, manufacturers can tailor components ranging from body panels to structural frames, thereby revolutionizing traditional automotive assembly and design practices.

The use of large carbon fiber sheets has revolutionized the construction industry, particularly in enhancing structural performance. According to a report by the European Composites Industry Association, carbon fiber composites offer substantial weight savings—up to 70% lighter than traditional materials like steel or concrete—while providing exceptional strength and stiffness. This is especially crucial in large-scale construction projects, where reducing weight without compromising structural integrity can lead to more efficient designs and reduced overall project costs.

Moreover, the superior tensile strength of carbon fiber sheets enhances the durability and longevity of structures. The American Institute of Steel Construction notes that structures reinforced with carbon fiber composites exhibit higher resistance to environmental factors, such as corrosion and fatigue, compared to conventional materials. This resistance results in lower maintenance costs and extended service life, making carbon fiber a preferred choice for applications in bridges, high-rise buildings, and infrastructure that demand high performance and low weight. As the industry moves towards more sustainable practices, the integration of carbon fiber technology is set to play a pivotal role in future construction methodologies.

The use of large carbon fiber sheets in various industries has gained significant traction due to their cost-effectiveness and sustainability. One of the primary advantages of carbon fiber is its lightweight nature, which leads to reduced material costs during manufacturing. By utilizing large sheets, manufacturers can optimize material usage, minimizing waste and ensuring maximum yield from each production cycle. This not only lowers overall costs but also contributes to a more efficient supply chain, allowing businesses to allocate resources to other critical areas.

Another vital aspect of carbon fiber sheets is their sustainability. As industries increasingly focus on reducing their carbon footprint, carbon fiber offers a compelling solution. The longevity and durability of carbon fiber products mean they require less frequent replacement, leading to lower overall material consumption. Furthermore, advancements in the recycling of carbon fiber materials aim to close the loop in manufacturing processes, making them more eco-friendly. Thus, industries that adopt large carbon fiber sheets not only benefit from economic savings but also participate in a more sustainable future by reducing environmental impact.

The application of large carbon fiber sheets is revolutionizing the electronics and medical device industries, particularly due to their exceptional thermal and electrical properties. Carbon fiber's lightweight nature combined with its high thermal conductivity makes it an ideal candidate for heat dissipation in electronic components. A recent report from the International Journal of Electronics states that the use of carbon fiber composites can enhance thermal management in devices by up to 25%, thereby improving efficiency and reliability.

In medical devices, the non-conductive yet thermally stable characteristics of carbon fiber are crucial for insulation in sensors and imaging systems. With the healthcare industry continuously striving for innovations that ensure patient safety and device efficacy, carbon fiber's capability to withstand high temperatures without compromising integrity has gained attention. According to a study published in the Journal of Medical Devices, incorporating carbon fiber sheets can reduce the weight of portable medical equipment by 30%, facilitating better mobility for both patients and healthcare providers.

Tip: When selecting carbon fiber materials for electronics or medical applications, ensure that they meet specific industry standards for thermal conductivity and electrical insulation to achieve optimal performance. Another important consideration is the thickness of the sheets, which can significantly influence both weight and thermal properties. Always consult with materials experts to align your project requirements with the best carbon fiber solutions available.

| Benefit | Description | Industries Used | Thermal Property | Electrical Property |

|---|---|---|---|---|

| Lightweight | Carbon fiber sheets are significantly lighter than metals, making them ideal for applications where weight reduction is crucial. | Aerospace, Automotive | Good thermal insulation | Excellent dielectric properties |

| High Strength | Carbon fiber materials offer high tensile strength and durability, suitable for demanding applications. | Construction, Sports Equipment | Resistant to temperature extremes | Low electrical conductivity |

| Corrosion Resistance | The material is resistant to various chemicals, making it ideal for harsh environments. | Marine, Chemical Processing | Does not corrode easily | Poor conductor |

| Thermal Stability | Carbon fiber sheets maintain their structural integrity at high temperatures. | Aerospace, Automotive | High thermal stability | Thermal conductive |

| Design Flexibility | Easily molded into complex shapes, providing versatility in design. | Consumer Electronics, Medical Devices | Custom thermal properties can be achieved | Can be engineered for specific electrical applications |

| Low Thermal Expansion | Minimizes changes in dimensions due to temperature changes. | Electronics, Precision Instruments | Highly stable under temperature changes | Low electrical expansion coefficient |

| Electromagnetic Interference Shielding | Effective for shielding electronic devices from EMI. | Telecommunications, Medical Devices | Can be combined with thermal barriers | High shielding effectiveness |

| Sustainability | Recyclability and eco-friendly production methods are becoming common. | Various industries, Green Technologies | Environmentally friendly | Can be developed to minimize electrical waste |

| Aesthetic Appeal | Sleek and modern appearance suitable for consumer products. | Consumer Electronics, Fashion | Not applicable | Not applicable |