-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

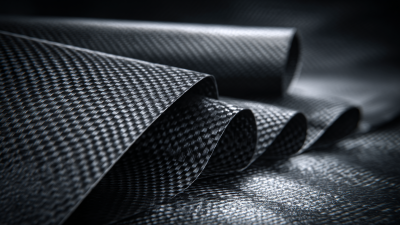

The advent of advanced materials in modern engineering has revolutionized design and construction processes, particularly with the introduction of Pultruded Carbon Fiber Bars. These bars exhibit exceptional strength-to-weight ratios and corrosion resistance, making them increasingly popular in various applications from aerospace to civil engineering. According to a report by the Global Carbon Fiber Market, the demand for carbon fiber is projected to grow at a CAGR of 9.5%, reaching USD 5.9 billion by 2026, highlighting the material's critical role in innovative engineering solutions.

Pultruded Carbon Fiber Bars, specifically, have emerged as a game changer, offering greater structural integrity while minimizing overall weight. This article will explore the myriad benefits of utilizing Pultruded Carbon Fiber Bars in contemporary engineering projects, emphasizing their performance, durability, and cost-effectiveness in an ever-evolving industry landscape.

Pultruded carbon fiber bars have gained significant attention in modern engineering due to their superior mechanical properties and lightweight nature. These composite materials are manufactured through a continuous process where carbon fibers are pulled through a resin bath and then cured, resulting in high-strength, low-weight components. According to a recent report from MarketsandMarkets, the global market for carbon fiber reinforced composites is projected to reach $34.6 billion by 2026, driven largely by innovations in the manufacturing process, such as pultrusion.

The unique combination of high tensile strength and rigidity makes pultruded carbon fiber bars ideal for various applications, including aerospace, automotive, and civil engineering. Data from the Carbon Fiber Composite Market Analysis highlights that pultruded carbon fiber exhibits tensile strengths exceeding 600 MPa, significantly outperforming traditional materials like steel, which has a tensile strength of around 250 MPa. Additionally, the low thermal expansion coefficient of these bars ensures dimensional stability in varying temperatures, making them suitable for precision engineering applications where tolerances are critical.

Furthermore, the corrosion resistance of pultruded carbon fiber bars is a major advantage in harsh environments. Studies indicate that these materials can withstand chemical exposure and do not require additional coatings, which not only reduces maintenance costs but also extends the lifespan of structural components. With an increasing emphasis on sustainability, their lightweight nature contributes to energy savings in transportation and construction sectors, further solidifying their role in the future of engineering.

In the realm of modern engineering, pultruded carbon fiber bars are capturing attention for their remarkable advantages, particularly in structural applications. Carbon fiber reinforced polymers (CFRPs) exhibit a high strength-to-weight ratio, making them an ideal choice for reducing overall weight in engineering projects without compromising structural integrity. A recent study highlights that CFRPs not only offer excellent tensile strength but also possess resistance to corrosion and fatigue, traits that are highly desirable in demanding environments.

Furthermore, advancements in manufacturing techniques, such as direct ink writing (DIW) for producing ultralight biomimetic helical composites, showcase the versatility and innovative potential of carbon fiber applications. Incorporating biomass and synthetic fibers into composite materials has also led to the development of high-performing bioresin-based FRPs. Studies indicate that integrating natural fibers with carbon fiber composites enhances their mechanical properties while promoting sustainability—offering a dual benefit of reinforcing strength and minimizing environmental impact. The push for advanced materials in sectors like automotive and aerospace underscores the growing relevance of carbon fiber in addressing both performance and eco-friendliness in modern engineering applications.

Pultruded carbon fiber bars have emerged as a game changer in various industries, thanks to their strength, lightweight nature, and resistance to corrosion. In the construction sector, these bars are being used to reinforce structures, offering superior tensile strength compared to traditional materials like steel. Their compatibility with concrete enhances the durability and longevity of buildings, making them a preferred choice for modern architectural designs.

In the automotive and aerospace industries, pultruded carbon fiber bars are gaining traction for their ability to reduce weight without compromising performance. This weight reduction is crucial for fuel efficiency and overall performance enhancement. Moreover, their high resistance to environmental factors ensures that components maintain their integrity over time, which is vital in high-stress applications.

**Tips:** When considering pultruded carbon fiber bars for your projects, always evaluate the specific load requirements and environmental conditions. Consulting with industry experts can help ensure optimal material selection that aligns with your project's goals. Additionally, keep an eye on advancements in manufacturing technologies that may further enhance the properties and applications of these materials.

| Industry | Application | Benefits | Material Properties |

|---|---|---|---|

| Construction | Reinforcement of beams and columns | High strength-to-weight ratio, corrosion resistance | Lightweight, durable |

| Automotive | Chassis components | Enhanced fuel efficiency due to weight reduction | High stiffness, low thermal expansion |

| Aerospace | Aircraft structures | Improved performance and lower emissions | Exceptional tensile strength, lightweight |

| Marine | Boat hulls and masts | Resistance to saltwater and UV damage | Robust, flexible |

| Electronics | Structural components in devices | Improved thermal management | Electrical insulating properties |

In modern engineering, the comparison of pultruded carbon fiber bars with traditional materials such as steel and aluminum is gaining significant attention. Carbon fiber bars are known for their exceptional strength-to-weight ratio, making them a preferred choice in various applications, from structural components to high-performance vehicles. Unlike traditional materials, carbon fiber exhibits outstanding resistance to corrosion and fatigue, which enhances longevity and reduces maintenance costs. This is particularly important in industries where durability and performance are critical.

Furthermore, the adaptability of carbon fiber in design allows for more streamlined and innovative structures compared to the bulkier and heavier alternatives. This flexibility in manufacturing not only leads to weight savings but also opens up new design possibilities that can improve overall efficiency and functionality. As engineers continue to push the boundaries of material science, the shift towards carbon fiber bars promises to revolutionize the way modern engineering challenges are approached, favoring a trend that emphasizes lightweight and robust solutions over conventional materials.

Incorporating pultruded carbon fiber bars into modern engineering projects offers numerous benefits, but realizing their full potential requires adherence to best practices. First and foremost, thorough material selection is crucial. Engineers must assess the specific requirements of their projects—considering factors such as load-bearing capacity, environmental conditions, and durability—when choosing the right type of carbon fiber bars. Utilizing the appropriate grade can significantly enhance performance and longevity, ensuring that the component meets all necessary standards and specifications.

Another key practice is to implement effective design strategies that leverage the unique properties of carbon fiber. This involves employing advanced modeling software to optimize the strength-to-weight ratio while minimizing material usage. Additionally, collaboration among cross-functional teams can lead to innovative applications that take full advantage of carbon fiber’s lightweight nature and resistance to corrosion. Providing comprehensive training for team members on handling and installation techniques will also ensure that these materials are used efficiently and safely, ultimately leading to successful project outcomes.