-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the evolving landscape of modern materials, Carbon Fiber Mesh Fabric has emerged as a revolutionary solution that offers numerous advantages for various applications. According to Dr. Emily Sanders, a leading expert in composite materials, "The lightweight yet incredibly strong properties of Carbon Fiber Mesh Fabric make it an ideal choice for projects that demand both durability and efficiency." This remarkable material not only enhances performance but also opens up new possibilities for innovation across multiple industries.

As we delve into the top 10 benefits of utilizing Carbon Fiber Mesh Fabric, it becomes clear that its unique characteristics—ranging from superior strength-to-weight ratio to excellent chemical resistance—address the diverse needs of engineers and designers alike. Whether in the aerospace sector, automotive applications, or even in construction, the versatility of Carbon Fiber Mesh Fabric sets it apart from traditional materials. Each benefit highlights how this innovative fabric contributes to smarter designs, cost savings, and improved project outcomes, positioning it as a game-changer in the realm of advanced material science.

Carbon fiber mesh fabric is becoming increasingly popular in various lightweight applications due to its impressive strength-to-weight ratio. According to recent studies, carbon fiber composites exhibit a tensile strength of around 500-600 MPa with a density as low as 1.6 g/cm³, making it significantly more resilient than traditional materials such as steel. This combination allows designers and engineers to create structures that are not only lighter but also maintain structural integrity, which is crucial in sectors like aerospace and automotive manufacturing.

Moreover, the versatility of carbon fiber mesh fabric enables its integration into innovative designs without sacrificing performance. For example, a report published by the Composite Materials Handbook indicated that products made from carbon fiber can achieve weight reductions of up to 50% compared to aluminum counterparts while also enhancing aerodynamic efficiency. This advantage is particularly beneficial in automotive applications, where weight savings directly correlate with improved fuel efficiency and overall performance. Emphasizing these attributes, carbon fiber mesh fabric offers an unparalleled solution for projects aimed at minimizing weight without compromising on strength and durability.

Carbon fiber mesh fabric stands out in the world of materials due to its exceptional durability and strength. Unlike traditional fabrics, carbon fiber mesh boasts a high tensile strength-to-weight ratio, making it an ideal choice for projects requiring robust support without adding unnecessary weight. This quality is particularly beneficial in applications such as aerospace, automotive, and construction, where structural integrity is paramount. The woven structure of the mesh further enhances its resistance to abrasion and impacts, ensuring that it maintains its form and function even under demanding conditions.

Moreover, carbon fiber mesh fabric offers superior resistance to chemical and environmental degradation compared to other fabric options. This resilience means that projects made with carbon fiber mesh are less likely to suffer from wear and tear due to exposure to harsh elements or corrosive substances. The longevity of carbon fiber projects not only contributes to lower maintenance costs over time but also supports sustainability by reducing the frequency of replacements. Ultimately, the unmatched strength and durability of carbon fiber mesh fabric make it a preferred choice for innovative projects looking to leverage the best materials available.

| Benefit | Description | Performance Indicator |

|---|---|---|

| Lightweight | Carbon fiber mesh is significantly lighter compared to traditional fabrics. | Weight Reduction: Up to 60% lighter than metals. |

| High Strength | Offers superior tensile strength, making it robust for demanding applications. | Tensile Strength: 3-5 times stronger than steel. |

| Corrosion Resistance | Resistant to chemicals and environmental factors, ensuring longevity. | Lifespan: Up to 20 years in harsh conditions. |

| Thermal Stability | Can withstand extreme temperatures without degrading. | Operating Temp: -40°C to 200°C. |

| Flexibility | Easily molded into complex shapes while maintaining strength. | Moldability: Ideal for custom applications. |

| UV Resistance | Withstands harmful UV radiation, preventing degradation. | UV Protection: Maintains integrity for over 10 years. |

| Low Maintenance | Requires minimal upkeep compared to other materials. | Maintenance Frequency: 1-2 times per year. |

| Aesthetic Appeal | Modern look that enhances product designs. | Design Versatility: Suitable for various industries. |

| Eco-Friendly | Manufactured using sustainable processes and recyclable materials. | Sustainability Rating: High for eco-conscious projects. |

| Cost-Effectiveness | Long-term savings due to durability and reduced replacement costs. | ROI: High due to longevity and low maintenance. |

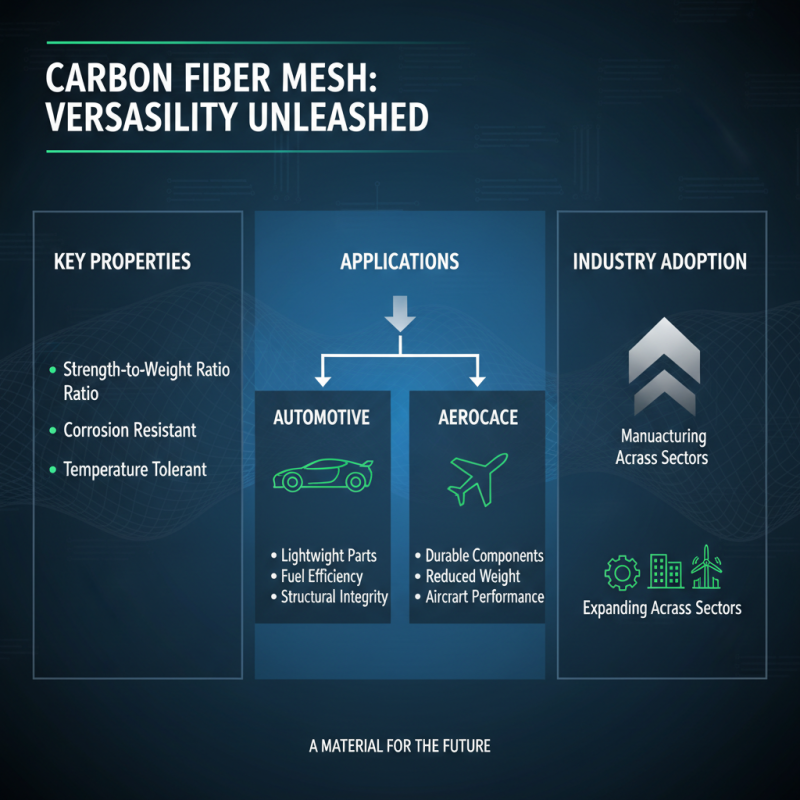

Carbon fiber mesh fabric is increasingly recognized for its versatility across various industries, making it a valuable material for many types of projects. Its exceptional strength-to-weight ratio, coupled with high resistance to corrosion and temperature fluctuations, allows this fabric to be used in sectors ranging from automotive to aerospace. In automotive applications, for instance, carbon fiber mesh provides lightweight yet strong parts that enhance fuel efficiency while maintaining structural integrity. Similarly, in the aerospace industry, this material is utilized to manufacture components that require both durability and reduced weight, contributing to overall aircraft performance.

Moreover, the application of carbon fiber mesh extends to construction and civil engineering, where its reinforcement capabilities significantly enhance the performance of concrete structures. By integrating carbon fiber mesh into concrete materials, engineers can improve tensile strength, reduce cracking, and extend the lifespan of buildings and infrastructures. Additionally, the fabric is being applied in sports equipment manufacturing, where its lightweight properties optimize performance without compromising safety. The ability to mold carbon fiber into complex shapes allows for innovative designs that are both functional and aesthetically pleasing in various products, showcasing the material’s adaptability across different domains.

The cost-effectiveness of using carbon fiber mesh fabric for high-performance builds is an attractive proposition for project designers and manufacturers alike. Carbon fiber mesh offers an excellent strength-to-weight ratio, which means substantial savings can be realized in terms of material usage without sacrificing performance. For projects that require durability and resilience, this innovative fabric allows for reducing the overall weight of structures or products, leading to lower fuel consumption in transportation and less energy expenditure during installation.

Additionally, the longevity and resistance to environmental factors provided by carbon fiber mesh fabric contribute to its cost-effectiveness. Unlike traditional materials, carbon fiber does not corrode or degrade easily, leading to decreased maintenance costs over time. This durability also means fewer replacements are required, maximizing the return on investment. Thus, whether in manufacturing, automotive design, or construction, using carbon fiber mesh fabric can streamline project costs while enhancing the overall quality of the build, proving to be a wise choice for those aiming to balance performance and budget constraints.

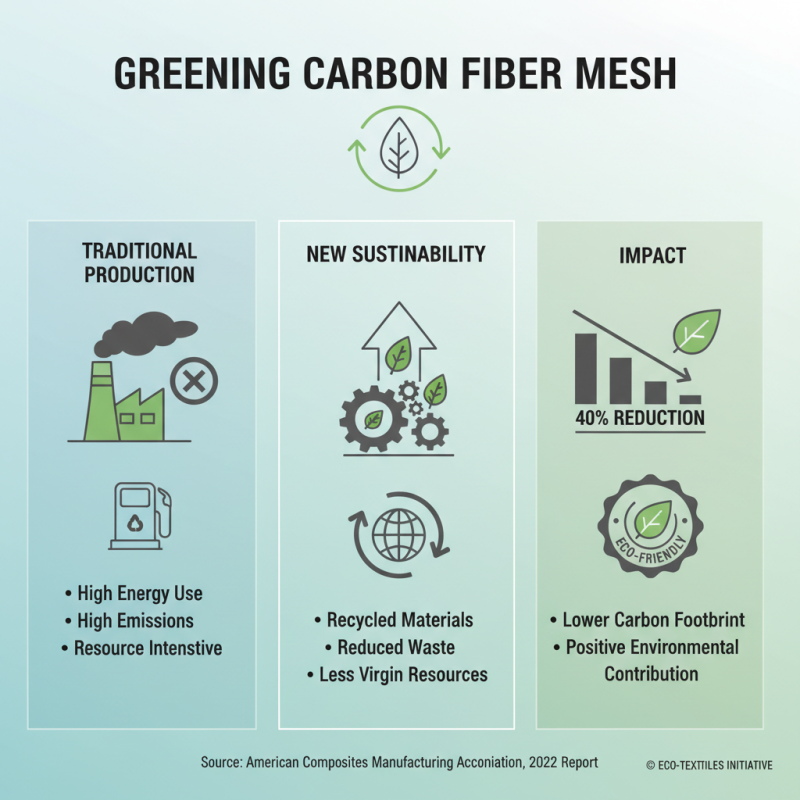

The sustainability of carbon fiber mesh fabric options represents a significant advancement in eco-friendly materials for various projects. Traditional carbon fiber production is often criticized for its high energy consumption and emissions; however, manufacturers are now adopting more sustainable practices. According to a 2022 report by the American Composites Manufacturing Association, using recycled carbon fiber can reduce the carbon footprint of the production process by up to 40%. This shift toward utilizing reclaimed materials not only minimizes waste but also reduces the reliance on virgin resources, contributing positively to the environment.

Moreover, carbon fiber mesh is known for its durability and longevity, which can lead to reduced material turnover and waste over the lifecycle of a product. A Life Cycle Assessment (LCA) study conducted by the European Composites Industry Association found that products made with carbon fiber fabrics can last up to three times longer than those made with traditional materials. This longevity not only benefits project economics but also aligns with the increasing demand for sustainable practices in manufacturing. By choosing carbon fiber mesh fabric, industries can make strides toward reducing their environmental impact while ensuring high performance and product lifespan.