-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, carbon fiber sheets have gained significant traction in various industries. According to Dr. Emily Carter, a renowned expert in materials engineering, "Carbon Fiber Sheet technology is a game changer for efficient designs." This statement encapsulates the transformative impact of carbon fiber sheets on project development.

With their lightweight properties and impressive strength, carbon fiber sheets offer a plethora of benefits. They enhance durability while reducing the overall weight of structures. Many engineers are turning to carbon fiber sheets to improve their designs and streamline production. Yet, the adoption of this material isn’t without challenges. The cost and complexity of processing carbon fiber sheets can be daunting for some projects.

However, the advantages often outweigh these hurdles. Carbon fiber sheets deliver unmatched performance and versatility across multiple applications. The balance of strength and weight makes them ideal for aerospace, automotive, and sporting goods. As industries evolve, understanding the full potential of carbon fiber sheets is essential to stay competitive. These sheets signify a shift towards innovation, but embracing them requires careful consideration and strategic planning.

Carbon fiber sheets are gaining popularity in engineering applications. Their unique properties make them suitable for various projects. They are light yet incredibly strong. This combination allows engineers to design structures that require less material. The sheets can reduce weight without compromising performance. This is crucial in fields like aerospace and automotive engineering.

One major benefit is their resistance to corrosion. Unlike metals, carbon fiber does not rust. This durability makes it ideal for environments exposed to harsh conditions. Engineers often face challenges in material selection. Choosing materials that withstand time is vital. Carbon fiber’s longevity helps reduce maintenance costs over time.

Tip: When selecting carbon fiber sheets, consider the thickness required for your project. Thicker sheets provide better strength, but they may add weight.

Another aspect to reflect on is the manufacturing complexity. While carbon fiber can be molded into various shapes, the production process can be intricate. Engineers must weigh cost against benefits. It’s essential to assess if the investment aligns with project goals. Remember, it’s okay to seek improvement in technological knowledge. Embracing new materials often leads to innovative solutions.

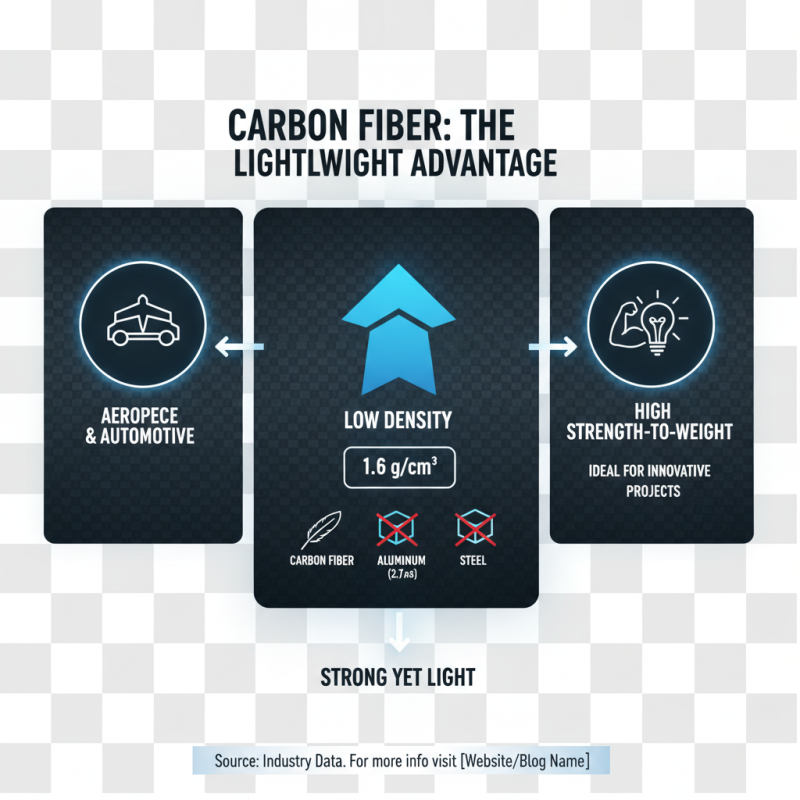

Carbon fiber sheets are widely recognized for their lightweight properties. The density of carbon fiber is about 1.6 grams per cubic centimeter, which is significantly lower than that of aluminum or steel. This lightweight nature makes carbon fiber an ideal choice for various industries, including aerospace and automotive. Projects requiring strong yet light materials benefit greatly from this unique characteristic.

In addition to being lightweight, carbon fiber sheets offer superior strength. They have a tensile strength of approximately 3.5 GPa, making them about five times stronger than steel. This exceptional strength-to-weight ratio allows for innovative designs that were previously thought impossible. Engineers can now create components that are not only lightweight but also durable. However, it’s essential to consider the high cost of production. This might lead to reflection on how to balance budget constraints with performance requirements.

Another advantage lies in the stiffness of carbon fiber. It provides a rigidity that is beneficial in structural applications. For instance, carbon fiber sheets can withstand considerable stress without deforming. Yet, some users find challenges in handling and installation due to their rigidity. Adaptation and experience are necessary for optimal results. Understanding these factors is crucial when integrating carbon fiber into projects.

Carbon fiber sheets are renowned for their exceptional durability. This material can withstand extreme conditions, making it ideal for various applications. It resists corrosion, wear, and impact. Unlike traditional materials, carbon fiber does not rust or degrade easily. This feature significantly prolongs the lifespan of projects using it.

The resistance characteristics of carbon fiber sheets are indeed impressive. They are lightweight yet incredibly strong. This unique combination makes them suitable for aerospace, automotive, and sporting goods industries. However, it's essential to consider the cost of carbon fiber materials. While its performance is unmatched, the investment is hefty. Users should weigh the benefits against their budget. Additionally, working with carbon fiber can be challenging. It often requires specialized tools and techniques for optimal results.

Carbon fiber sheets have gained immense popularity across various industries due to their remarkable versatility. In aerospace, for instance, these sheets reduce weight while maintaining strength. This property improves fuel efficiency significantly. Engineers appreciate how easy it is to mold and shape carbon fiber into various components, allowing for innovative designs in aircraft.

In the automotive sector, carbon fiber sheets enhance performance and safety. They can be integrated seamlessly into vehicle structures. This leads to lighter frames and better fuel economy. However, the high cost of production can be a barrier for some manufacturers.

In construction, carbon fiber sheets bolster structural integrity, offering resistance to wear and tear. Yet, their long-term durability remains a topic for discussion. While they provide excellent support, ensuring proper application is crucial for maximizing benefits.

Innovation is key in utilizing carbon fiber sheets effectively. Industries find new applications regularly, yet challenges exist. There are limitations in heat resistance, which can be problematic in some fields. Continuous research is necessary to address these concerns and push the boundaries of what carbon fiber can achieve. Its potential is vast, yet the journey of improvement and adaptation continues.

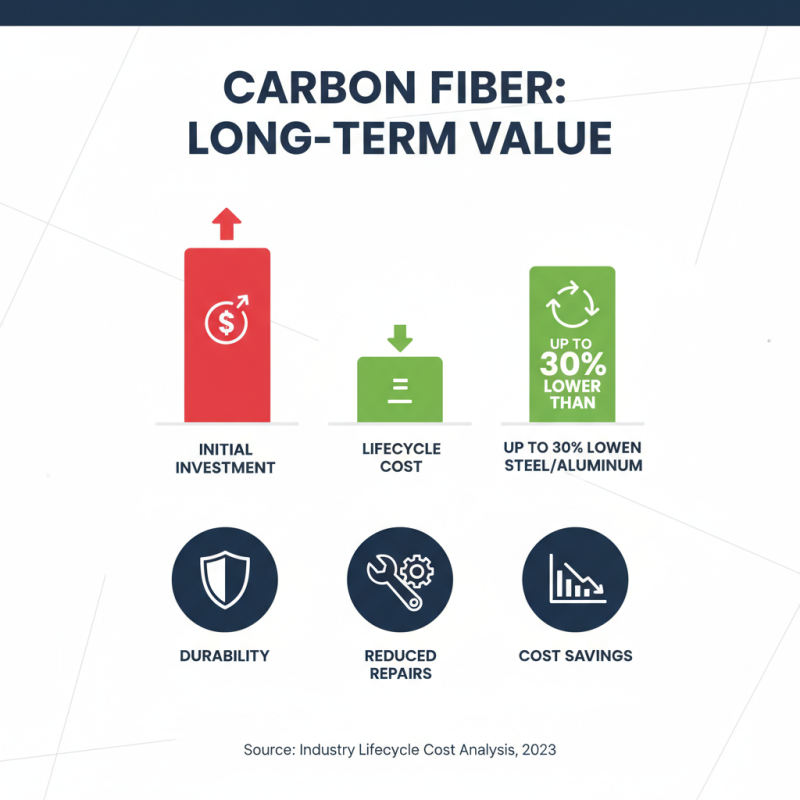

The long-term cost-effectiveness of using carbon fiber sheets in various projects is often underestimated. Although the initial investment may be higher than traditional materials, the benefits frequently outweigh these costs. Studies show that carbon fiber has a lifecycle cost that can be up to 30% lower than aluminum or steel when factoring in repair and replacement costs.

Carbon fiber is lightweight yet strong, which means reduced transportation and installation costs. It can lead to lower energy consumption, especially in automotive and aerospace applications. For example, lighter vehicles consume less fuel over time, translating to significant savings. A report from the Composites Market highlights that projects incorporating carbon fiber can see performance improvements by over 15%, ultimately driving down operational costs.

Tips: Always analyze the project requirements before choosing materials. Consider maintenance and longevity. Evaluate if upfront costs are justified by long-term savings.

Using carbon fiber can still present challenges. Its complex fabrication process may lead to higher upfront labor costs. Additionally, not all projects can fully utilize its properties, leading to wasted investment. Understanding the specific attributes needed in your project is vital. Employing expert analysis helps mitigate these risks.