-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

As the demand for lightweight yet strong materials continues to rise, Large Carbon Fiber Sheets emerge as a game-changer for various industries. Renowned expert Dr. James Reynolds, a materials scientist, emphasizes, "The future belongs to those who adopt innovative materials like carbon fiber." His insights highlight the importance of these sheets in modern engineering and design.

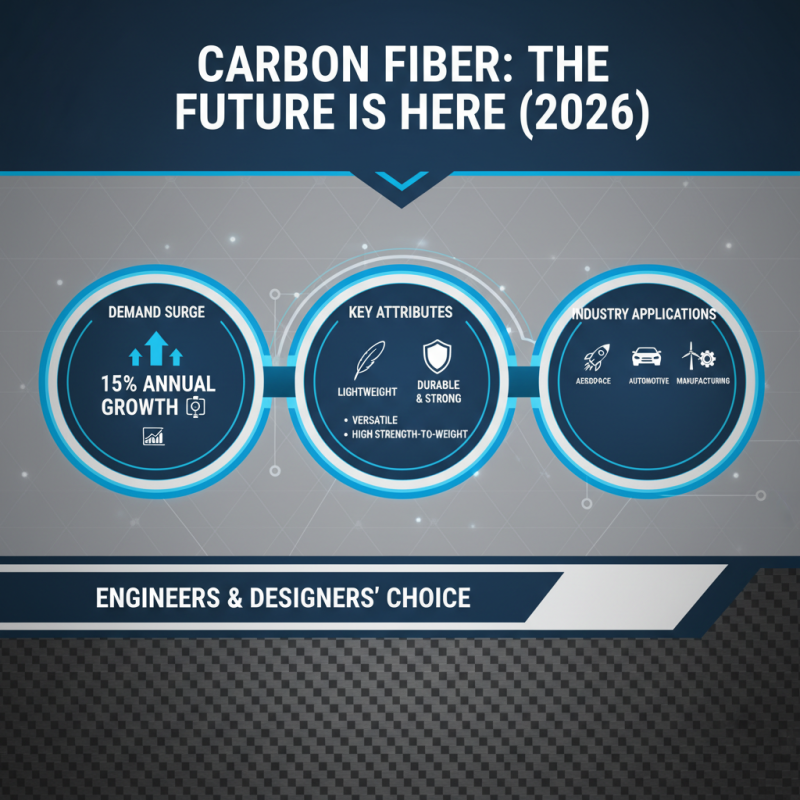

Large Carbon Fiber Sheets offer unmatched strength-to-weight ratios. They are extensively used in aerospace, automotive, and sporting goods sectors. Imagine the potential of a bicycle frame that weighs less than a feather yet withstands heavy impacts. These sheets are revolutionizing how we approach construction and fabrication.

However, not all Large Carbon Fiber Sheets are created equal. Many options in the market lack the durability or flexibility needed for specific projects. Buyers should thoroughly research and reflect on their choices to avoid costly mistakes. The right selection of Large Carbon Fiber Sheets can make or break a project’s success.

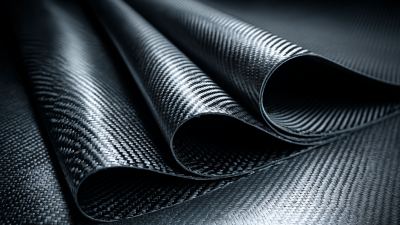

Carbon fiber sheets have gained popularity in various industries due to their impressive strength-to-weight ratio. These materials are made from intertwined carbon fibers, creating a composite that is both lightweight and incredibly durable. They excel in applications ranging from aerospace to automotive and even sports equipment. With these sheets, engineers can achieve high performance while reducing overall weight.

The versatility of carbon fiber sheets is remarkable. They can be cut and shaped to suit specific project needs. For instance, in automotive design, reducing weight can improve fuel efficiency. In the sports industry, carbon fiber enhances equipment performance. However, working with these materials can present challenges. Proper cutting techniques must be employed to avoid fraying. Additionally, the price point can deter some projects. This means not every application may justify the investment in carbon fiber sheets.

Some may find it difficult to identify the right thickness or finish for their needs. The variety of options in the market can be overwhelming. This leads to second-guessing decisions. It's important to calculate the project requirements carefully. Understanding how carbon fiber interacts with different environments is crucial. This helps in making informed choices that will withstand the test of time.

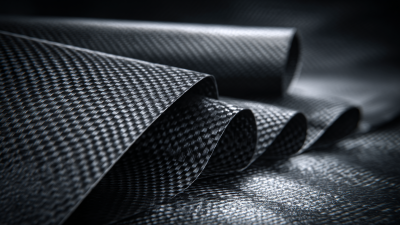

When choosing large carbon fiber sheets, several factors play a crucial role. The thickness of the sheets is significant. Industry standards show that sheets between 1mm to 3mm provide an excellent balance of weight and strength. Thicker sheets tend to be more rigid, but they may add unnecessary weight to your projects.

Another critical aspect is the weave pattern. Different weave styles can affect performance. A 2x2 twill weave is often preferred in many applications for its flexibility and aesthetic appeal. According to recent studies, the mechanical properties can vary with weave patterns. This can influence the overall durability of your project.

The surface finish also matters. A matte finish can help with adhesion, while a gloss finish may enhance aesthetics. Getting the right finish can sometimes be overlooked. Many users report issues with bonding when the surface isn't properly prepared. Thickness, weave pattern, and finish all contribute to the final performance of large carbon fiber sheets in various applications.

In 2026, carbon fiber sheets continue to dominate various industries. These sheets are favored for their lightweight yet durable nature. A recent industry report indicates that the demand for carbon fiber materials has increased by over 15% annually. Applications range from aerospace to automotive. Engineers and designers appreciate their versatility and strength.

When selecting carbon fiber sheets, consider thickness, weight, and weave patterns. Thicker sheets generally offer more strength but may be heavier. Weaves impact flexibility and appearance. The market now offers various models catering to specific needs, from high-performance racing to consumer products. Popular choices often exhibit unique characteristics that appeal to niche markets.

Tips: Always check for certifications and quality standards in carbon fiber sheets. Not all options meet stringent industry requirements. Be cautious of overly cheap alternatives—they may compromise performance. Regularly review the evolving market for new trends and technologies. Each advancement can significantly influence your project outcomes.

When considering large carbon fiber sheets for various projects in 2026, it's essential to analyze both price and performance. These sheets have gained popularity due to their lightweight nature and strength. Projects range from automotive components to aerospace applications. However, not all options deliver the same level of quality. Some sheets can be surprisingly fragile despite their advertised durability.

In terms of pricing, the cost can vary significantly. Budget-friendly options might be appealing, yet they may sacrifice some performance features. This is a common dilemma. Higher-priced sheets generally offer better quality but might be beyond reach for hobbyists. It's crucial to balance your budget with your project's requirements. The performance of the material should not be compromised for a lower price point, especially in demanding applications.

When selecting a sheet, check for specifications like tensile strength and weight tolerance. Detailed performance metrics can provide insight into their suitability for your tasks. Sometimes, the price reflects the quality. Yet, overly expensive options do not guarantee excellence. A thorough comparison will lead to better decisions. Each project is unique, and the right choice often emerges through careful assessment and reflection.

As we look towards 2026, the landscape of carbon fiber sheet technology is evolving rapidly. Current reports indicate that the global market for carbon fiber is projected to reach $9 billion by 2026, driven by advancements in manufacturing techniques and material composition. Industries like aerospace, automotive, and renewable energy are increasingly adopting carbon fiber sheets for their lightweight and high-strength properties. These trends reflect a growing demand for materials that not only enhance performance but also contribute to sustainability goals.

Emerging technologies, such as 3D printing and automated production processes, are transforming the way carbon fiber sheets are made. According to recent data, 3D printing of carbon fiber-reinforced polymers has increased by 15% annually. This method allows for more complex designs and reduces material waste. However, challenges remain. For example, ensuring consistent quality in printed sheets can be difficult. Moreover, high production costs can hinder wider adoption across various sectors.

The use of carbon fiber sheets is also expanding into new applications. Innovations in composite materials are making these sheets more affordable and accessible. For instance, the construction industry is experimenting with carbon-fiber-reinforced structures, aiming for stronger and more durable buildings. Despite the potential, the industry must address issues related to recyclability. Current recycling methods are efficient but not widespread. Future developments might focus on creating fully recyclable carbon fiber composites, fostering a circular economy.