-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the evolving world of materials, "Large Carbon Fiber Sheets" stand out for their versatility and strength. Dr. Emily Foster, a prominent expert in composite materials, states, “Carbon fiber sheets are revolutionizing industries by providing unmatched strength-to-weight ratios.” This insight highlights the growing significance of large carbon fiber sheets in various applications.

From aerospace to automotive, these sheets are becoming crucial. Their lightweight nature enhances performance while maintaining structural integrity. For example, an aircraft wing made from large carbon fiber sheets reduces fuel consumption, showcasing the material's impact. However, choosing the right sheet can be perplexing. The market offers countless options, each catering to different needs and applications.

Nonetheless, it's essential to reflect on the sustainability of carbon fiber production. The environmental impact remains a concern. As industries embrace these materials, they must also seek methods to minimize waste and improve recycling processes. This balance is vital for future advancements in large carbon fiber sheet applications.

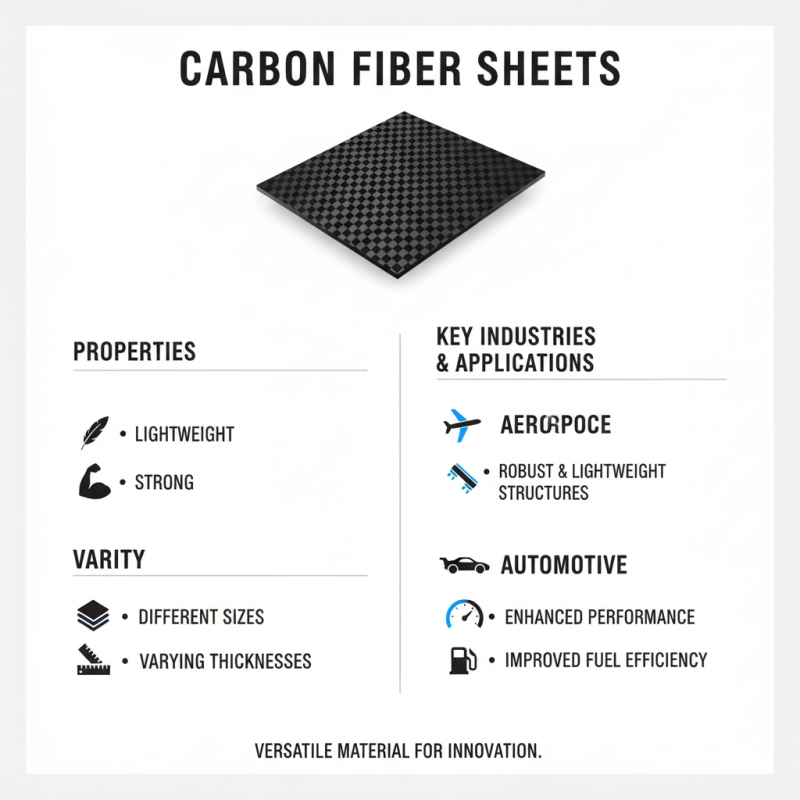

Carbon fiber sheets have become increasingly popular in various industries due to their lightweight and strong properties. These sheets come in different sizes and thicknesses, making them suitable for a range of applications. In aerospace, carbon fiber sheets help create robust yet light structures. For automotive uses, they enhance performance and fuel efficiency.

In construction, these sheets provide impressive strength, often reinforcing structures without adding significant weight. Their resistance to corrosion is also a crucial factor in outdoor applications. However, the production process can sometimes lead to imperfections. It's essential to inspect each sheet closely for any defects that may affect performance.

Despite their advantages, using carbon fiber sheets requires careful consideration. They can be more costly than traditional materials. Additionally, not all applications may benefit from their unique properties. Evaluating specific needs is vital to ensure they are the right choice. Balancing these factors can help achieve better outcomes in projects.

When selecting large carbon fiber sheets, there are several key features to consider. The thickness of the sheets impacts their strength and weight. Thicker sheets generally provide better strength but can add unwanted weight. Consider the balance between rigidity and flexibility for your specific application.

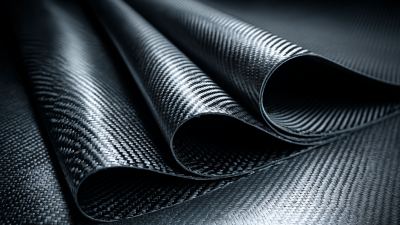

Another important factor is the weave pattern. Different weaves can alter the mechanical properties of the material. A plain weave may offer good balance, while a twill weave can provide enhanced strength and aesthetic appeal. Evaluate how these characteristics align with your project's requirements.

Don’t overlook the surface finish. A smoother surface can improve bonding during assembly. However, some applications may benefit from a textured finish for better grip. Lastly, think about availability. Sourcing high-quality sheets can be challenging, so plan ahead. The decisions you make may need reevaluation as your project evolves.

When it comes to aerospace applications, large carbon fiber sheets are essential. These sheets provide high strength and low weight, ideal for aircraft manufacturing. Engineers prioritize materials that can withstand extreme conditions, and carbon fiber excels in this regard. It resists fatigue, making it perfect for long-lasting structures.

A major consideration is the quality of these sheets. Defects in the material can lead to catastrophic failures. That's why sourcing from reliable suppliers is crucial. Testing samples before full production can save time and resources. Even minor inconsistencies can affect overall performance.

In aerospace, performance is paramount. Each component plays a role in safety and efficiency. Designers often face challenges with cost versus quality. Balancing these factors is essential for successful projects. The right carbon fiber sheet can make a significant difference. It can enhance fuel efficiency and reduce emissions. Understanding the specific needs of your project is vital for choosing the best material.

When it comes to the automotive industry, large carbon fiber sheets play a pivotal role. These materials offer exceptional strength while remaining lightweight. This unique combination makes them ideal for various automotive applications, from body panels to structural components. Using carbon fiber can enhance performance and fuel efficiency, a vital consideration in today’s market.

However, not every carbon fiber sheet is created equal. Quality can vary greatly among products. Some sheets may display inconsistencies in thickness or resin application. These flaws can lead to weak points in the final product. It’s crucial to evaluate the specifications and ask for samples to ensure reliability.

Moreover, the cost of large carbon fiber sheets can be daunting. Budget constraints often lead to tough decisions. Striking a balance between cost and quality is essential. Selecting economical options without sacrificing performance can be challenging. Regularly reviewing the latest innovations in carbon fiber technology can help manufacturers make informed choices.

When examining the market for large carbon fiber sheets in 2026, pricing and supplier comparison reveals significant variations. The average pricing for these sheets ranges from $20 to $50 per square foot, depending on thickness and quality. According to industry reports, demand for carbon fiber materials is expected to grow by 12% annually. This growth is driven by applications in aerospace, automotive, and sporting goods.

Supplier options are diverse, but not all offer competitive prices. The top suppliers supply over 60% of the market. Smaller suppliers may offer lower prices, but quality can vary widely. In a recent survey, 40% of buyers expressed dissatisfaction with the consistency of smaller vendors. Quality control is a major concern. This inconsistency can impact the final product reliability.

Buyers must navigate these dynamics carefully. Many industry experts recommend that companies assess their specific needs before making decisions. Sometimes, the cheapest option may not deliver value. It is essential to balance cost with quality. Few suppliers provide transparent data on material specifications. This makes it challenging for buyers to make informed choices. Ultimately, a careful analysis of each supplier's offerings can lead to better purchasing decisions.