-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Carbon Fiber Laminate Sheets are increasingly popular in various industries due to their unique properties. John Smith, a renowned expert in materials engineering, once said, "The versatility of carbon fiber laminate is transforming modern manufacturing." This underscores the material's impact on design and functionality.

These sheets are lightweight, strong, and resistant to temperature changes. They are used in aerospace, automotive, and sporting goods. However, not every application benefits equally. The cost is higher than traditional materials. Some find it difficult to work with. Understanding the right context for use is crucial.

Furthermore, the sustainability of carbon fiber is under scrutiny. While it offers many advantages, we must consider environmental impacts. Companies should focus on responsible sourcing. As technology evolves, so does the potential for improved sustainability. Carbon Fiber Laminate Sheets continue to have a promising future. However, industry players must reflect on their practices.

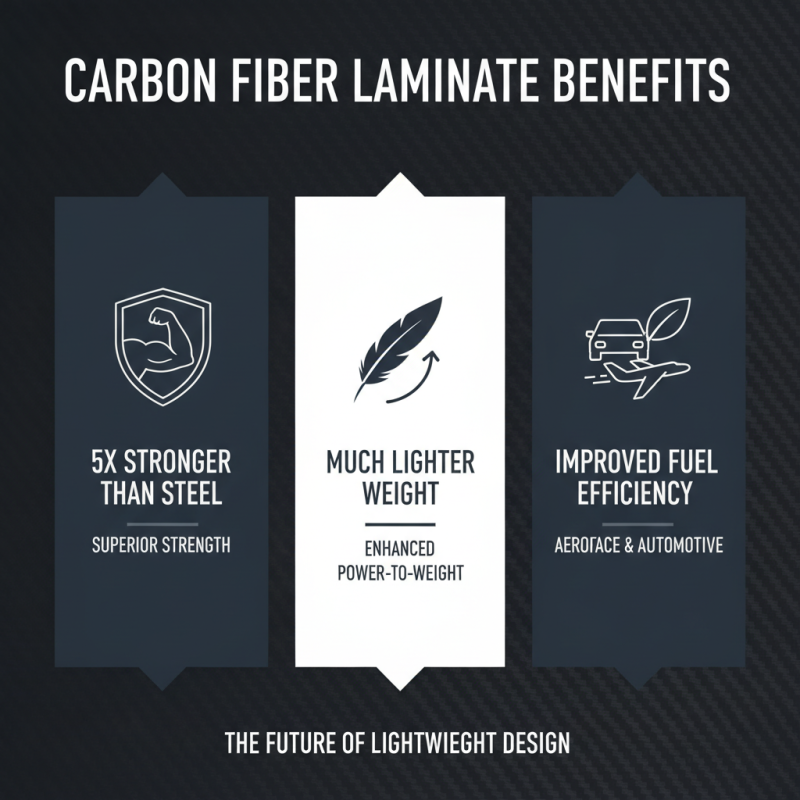

Carbon fiber laminate sheets have gained popularity in various industries due to their impressive strength-to-weight ratio. These sheets are primarily composed of carbon fibers embedded in a polymer resin. This unique composition allows them to outperform traditional materials like metals and plastics in many applications. According to industry reports, carbon fiber laminates can be up to five times stronger than steel while being significantly lighter.

The manufacturing process of carbon fiber laminate sheets involves layering carbon fibers and resin to create a composite. The sheets can be tailored for specific characteristics, such as flexibility or rigidity, depending on the intended use. For instance, a report from the Composites Market Research Group indicates that the aerospace sector frequently utilizes these laminates for their structural components, where strength and weight are critical.

Despite their advantages, carbon fiber laminate sheets come with some challenges. They can be more expensive than traditional materials, which can limit their adoption in certain applications. Additionally, the recycling of carbon fiber composites is still an ongoing concern. Research shows that around 80% of carbon fiber products currently end up in landfills, highlighting a significant area for improvement within the industry. This emphasizes the need for innovations in sustainability and recycling methods.

Carbon fiber laminate sheets are widely used across various industries due to their unique properties. These sheets are lightweight yet incredibly strong. They resist corrosion and are heat resistant. These characteristics make them a popular choice for the aerospace sector. Aircraft components often utilize these sheets to reduce weight while maintaining safety.

In the automotive industry, carbon fiber laminate sheets improve performance. They contribute to the lightweight design of vehicles, enhancing speed and fuel efficiency. Sports equipment manufacturers also benefit from these materials. Bicycles and tennis rackets made with carbon fiber offer better durability. The applications are diverse, reflecting the versatile nature of these sheets.

However, working with carbon fiber requires caution. The production process can create hazardous dust. Proper handling and safety measures are crucial. Additionally, the higher cost can be a barrier for smaller enterprises. Balancing performance and budget is an ongoing challenge for many businesses. In exploring these applications, it’s vital to weigh benefits against potential risks.

Carbon fiber laminate sheets have gained popularity for various applications. Their strength-to-weight ratio is impressive, making them a preferred choice for industries such as aerospace and automotive. In fact, studies show that carbon fiber can be up to five times stronger than steel while being much lighter. This unique property allows for more efficient designs and improved fuel economy.

Using carbon fiber laminate bedsheets also leads to lower maintenance costs over time. Unlike traditional materials, they resist corrosion and fatigue. Data from industry reports indicate that structures using carbon fiber can have a longer lifespan, requiring less frequent repairs. However, costs can be higher at the initial stages, which may deter some users.

Moreover, the aesthetic appeal is notable. Carbon fiber sheets can be finished in various ways, providing a sleek, modern look. However, some may find the appearance too industrial for certain applications. Balancing function and style can be tricky. Overall, carbon fiber laminate sheets present unique advantages worth considering.

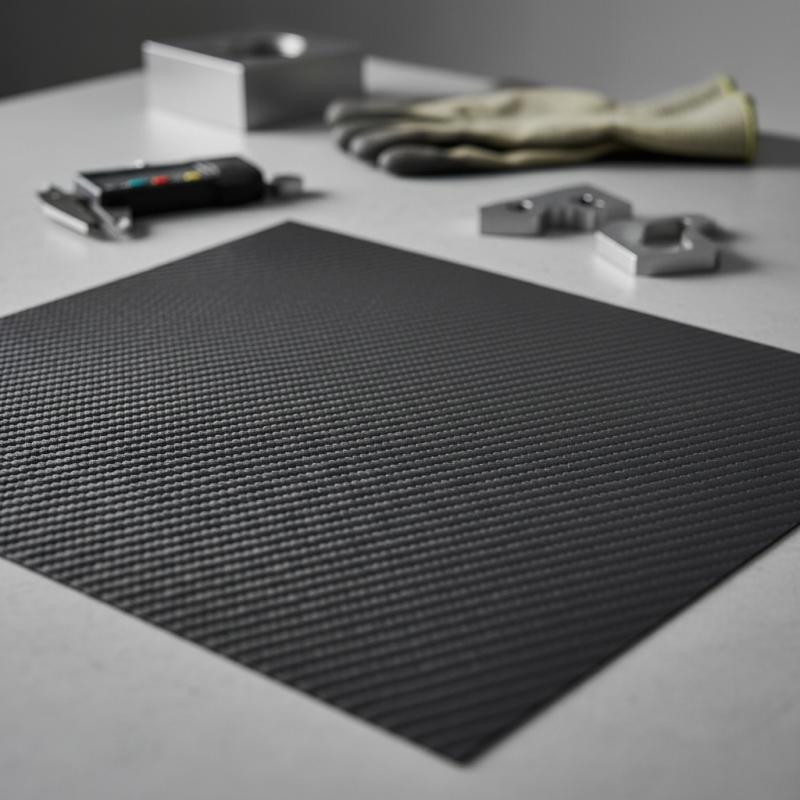

When selecting carbon fiber laminate sheets, several key factors should be carefully considered. First, the thickness of the laminate is crucial. Thicker sheets often provide greater strength and durability, which can be essential for demanding applications. Reports indicate that sheets can range from 0.5 mm to 10 mm. This range allows for versatility, but also presents challenges. Thinner sheets may not always offer the required structural integrity.

Another critical aspect to look at is weight. Carbon fiber is renowned for its lightweight properties. Yet, the actual weight can differ based on the construction methods used. For instance, some laminates may include additional materials that can add unwanted bulk. It’s essential to balance the need for lightweight performance with the overall strength required for specific applications.

Additionally, consider the environmental conditions where the laminate will be used. Exposure to moisture or extreme temperatures can affect performance. Some studies show that carbon fiber can lose structural integrity when subjected to certain elements. Ensuring that the laminate is suitable for the intended environment is vital. Testing and certifications can help in making an informed choice, but not all products undergo rigorous evaluation. Thorough research is crucial for optimal selection.

Maintaining carbon fiber laminate sheets can extend their longevity. Regular cleaning is essential. Use a soft cloth and mild detergent. Avoid abrasive cleaners, as they can scratch the surface. According to industry reports, proper maintenance can significantly enhance the lifespan of these sheets, leading to cost savings over time.

Humidity control matters too. High humidity can damage the adhesive layers in carbon fiber laminates. Ideally, keep the environment around 40-60% humidity. If moisture gets trapped, it may lead to delamination. Take time to inspect for any signs of wear or damage. Little cracks or discoloration can indicate that care is needed.

Storage is another aspect to consider. Carbon fiber laminate sheets should be stored in a cool, dry place. Direct sunlight can degrade the material. These sheets should be protected from heavy impacts, as they are strong yet can be brittle under pressure. Remember, mistreating the sheets can lead to problems in the future. Evaluate your handling practices regularly to ensure your carbon fiber laminates remain in top condition.

| Use Case | Benefit | Maintenance Tips | Lifespan |

|---|---|---|---|

| Aerospace Components | High strength-to-weight ratio | Regular inspections for cracks | 20+ years with proper care |

| Automotive Parts | Improved fuel efficiency | Clean with mild detergent | 10-15 years |

| Sports Equipment | Lightweight and durable | Store in a cool, dry place | 5-10 years depending on use |

| Consumer Electronics | Shock resistance | Avoid extreme temperatures | 3-7 years |

| Marine Applications | Corrosion resistance | Rinse with fresh water after use | 15+ years with care |