-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

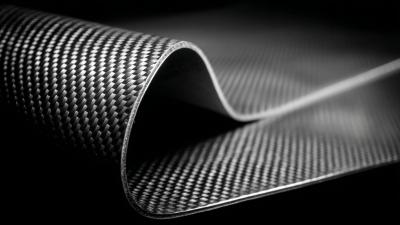

The aerospace industry is at the forefront of innovation, constantly seeking materials that enhance performance while reducing weight and costs. Among the standout materials leading this transformation is the Carbon Fiber Laminate Sheet. According to a report by MarketsandMarkets, the aerospace composite market is projected to reach $6.93 billion by 2024, with carbon fiber composites playing a pivotal role in this growth due to their exceptional strength-to-weight ratio.

These laminate sheets not only contribute to fuel efficiency but also improve the durability and lifespan of aircraft components. As airlines and manufacturers increasingly focus on sustainability and operational efficiency, the adoption of Carbon Fiber Laminate Sheets is set to revolutionize aerospace engineering, ushering in an era of high-performance, lightweight aircraft that promise to elevate aviation standards and operational economics to unprecedented heights.

These laminate sheets not only contribute to fuel efficiency but also improve the durability and lifespan of aircraft components. As airlines and manufacturers increasingly focus on sustainability and operational efficiency, the adoption of Carbon Fiber Laminate Sheets is set to revolutionize aerospace engineering, ushering in an era of high-performance, lightweight aircraft that promise to elevate aviation standards and operational economics to unprecedented heights.

Carbon fiber laminate sheets are becoming a cornerstone in aerospace design innovations, fundamentally transforming the way aircraft engineers approach material selection and structural integrity. According to a report by MarketsandMarkets, the global market for carbon fiber in the aerospace sector is projected to reach $3.14 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.4%. This surge is driven by the material's exceptional strength-to-weight ratio and fatigue resistance, making it an ideal choice for both commercial and military aircraft.

The integration of carbon fiber laminate sheets into aerospace engineering allows for more efficient fuel consumption due to their lightweight nature. The European Commission's research indicates that the use of advanced composite materials can lead to up to a 20% reduction in fuel consumption for new aircraft designs. Moreover, these laminate sheets enable the creation of complex geometries and streamlined designs, contributing to improved aerodynamic performance. As innovations continue, the role of carbon fiber will likely expand, paving the way for next-generation aircraft that are not only more efficient but also more sustainable, aligning with the industry's goals for reduced environmental impact.

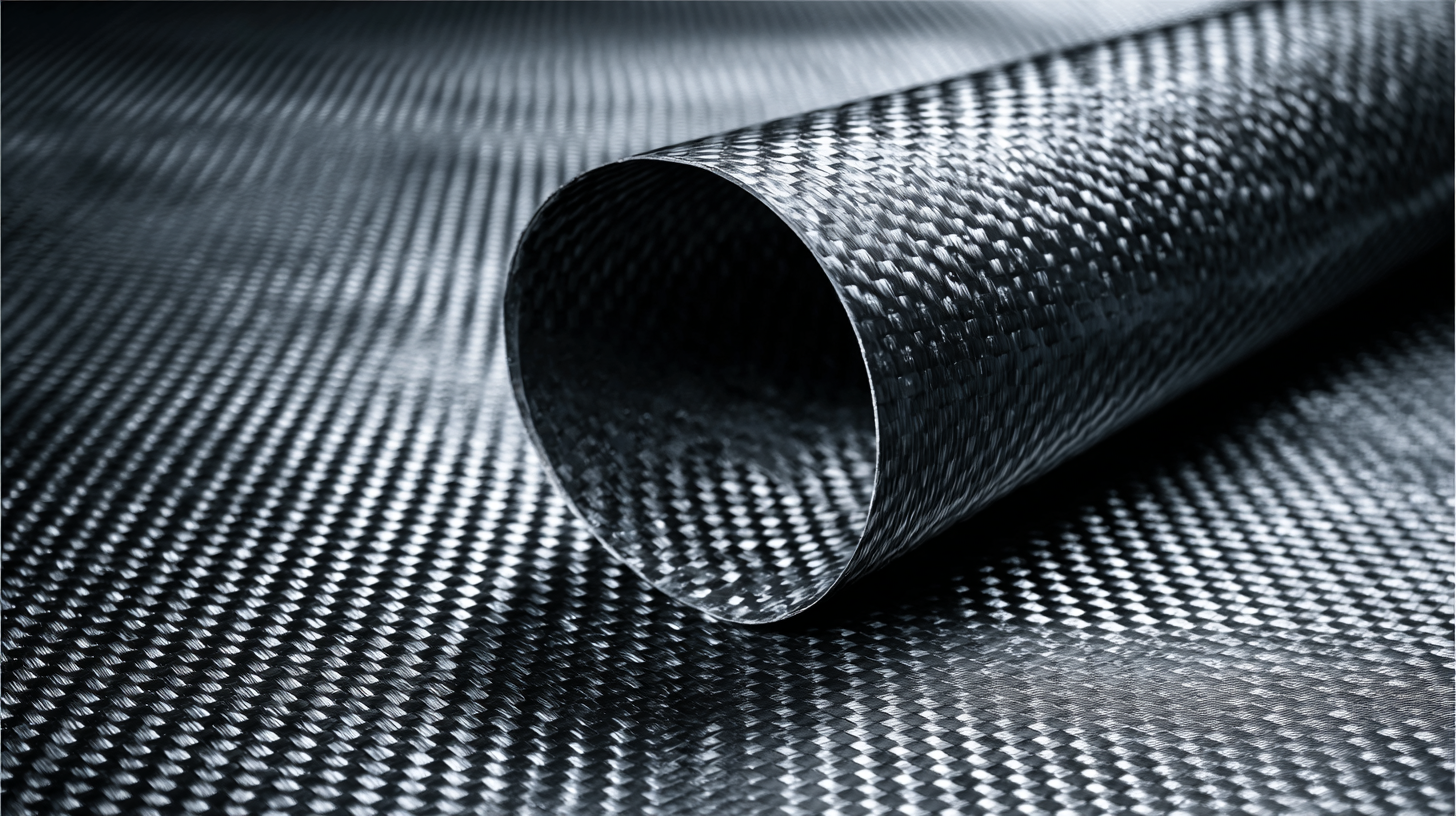

Carbon fiber laminate sheets have quickly become a game-changer in aerospace engineering,

offering numerous advantages over traditional materials like aluminum and steel. One of the most significant benefits is their

exceptional strength-to-weight ratio. According to a report by the

Global Carbon Fiber Market, carbon fiber is about five times stronger than steel while

being significantly lighter. This characteristic not only enhances fuel efficiency but also

increases payload capacity, allowing aircraft to carry more passengers or cargo while reducing

operational costs.

Carbon fiber laminate sheets have quickly become a game-changer in aerospace engineering,

offering numerous advantages over traditional materials like aluminum and steel. One of the most significant benefits is their

exceptional strength-to-weight ratio. According to a report by the

Global Carbon Fiber Market, carbon fiber is about five times stronger than steel while

being significantly lighter. This characteristic not only enhances fuel efficiency but also

increases payload capacity, allowing aircraft to carry more passengers or cargo while reducing

operational costs.

Furthermore, carbon fiber's resistance to corrosion and fatigue sets it

apart from conventional materials. A study published in the Journal of Aircraft

indicates that aircraft components made from carbon fiber can last up to three times longer than those made of aluminum when exposed

to harsh environmental conditions. This durability translates to lower maintenance costs and longer service life for aircraft, making

carbon fiber an economically attractive option for manufacturers. As the aerospace industry

increasingly emphasizes sustainability, the shift toward carbon fiber materials is expected to accelerate, paving the way for

innovative designs and improved performance in aviation.

Carbon fiber laminate sheets have become a game changer in aerospace engineering, significantly enhancing aircraft performance and efficiency. According to a report from the IATA, the aviation industry aims to achieve a 50% reduction in net carbon emissions by 2050, and the implementation of lightweight materials like carbon fiber is central to this goal. These advanced composites can reduce aircraft weight by up to 20%, resulting in lower fuel consumption and increased payload capacity. For instance, the Boeing 787 Dreamliner, which employs carbon fiber-reinforced plastic extensively, achieves a 20% improvement in fuel efficiency compared to similar-sized aircraft.

When integrating carbon fiber laminate sheets into aircraft design, engineers can also leverage enhanced aerodynamic performance. Research by the EASA indicates that improvements in aerodynamics can lead to a 10% reduction in drag, which directly contributes to fuel savings. This means airlines can operate more efficiently while maintaining competitive ticket pricing.

Tips: To maximize the benefits of carbon fiber laminate sheets, aerospace engineers should focus on optimizing the design and layering techniques. By strategically placing carbon fiber layers where strength and stiffness are paramount, they can further enhance structural integrity while achieving remarkable weight savings. Emphasizing collaboration between materials scientists and aerodynamics experts can lead to innovative approaches that push the boundaries of current aircraft capabilities.

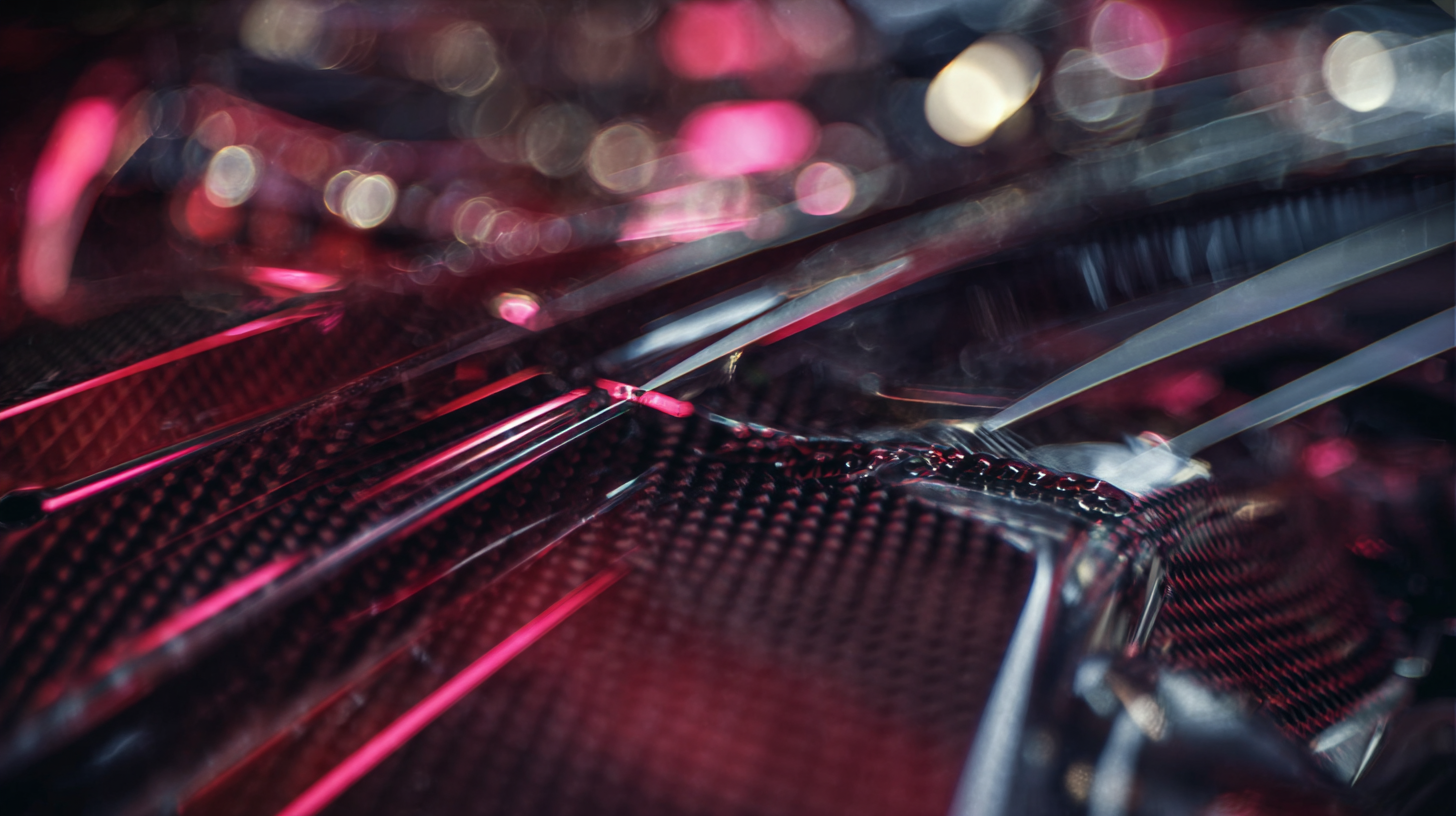

Carbon fiber technologies are set to play a pivotal role in shaping the future of aerospace engineering. With the emergence of low-altitude economic opportunities, the demand for carbon fiber composite materials continues to surge. Recent breakthroughs in manned low-altitude vehicles in the Beijing-Tianjin-Hebei region illustrate the growing application of carbon fiber, which is praised for its lightweight and high-strength properties essential for modern aircraft design.

Tips: When considering the integration of new materials like carbon fiber in aerospace, manufacturers should focus on improving material processing techniques and enhancing supply chain efficiencies. Collaborating with research institutions can also accelerate innovation, ensuring that new applications are both practical and profitable.

As the aerospace sector evolves, trends indicate a shift towards sustainable and high-performance composites. The 2025 vision for China's composite materials industry highlights the potential for carbon fibers to significantly influence aerodynamics and fuel efficiency in aircraft. By investing in carbon fiber technology, companies not only enhance their competitive advantage but also contribute to environmental sustainability initiatives within the aerospace domain.

Tips: Stakeholders should remain informed about advancements in carbon fiber production and applications. Continuous engagement with industry forums and exhibitions can provide valuable insights into emerging technologies and market needs, guiding strategic development efforts.

The aerospace industry has seen significant advancements with the integration of carbon fiber laminate sheets into various projects. A notable example is the Boeing 787 Dreamliner, which incorporates carbon fiber reinforced polymer (CFRP) in over 50% of its airframe. This not only reduces the aircraft's overall weight but also enhances its fuel efficiency and operational range. The use of carbon fiber allows for more complex and aerodynamically efficient designs, leading to improved performance and lower emissions.

Another groundbreaking case is the Airbus A350, wherein carbon fiber materials help achieve a lighter structure without compromising safety or strength. This aircraft's fuselage is primarily made of CFRP, which has contributed to a significant reduction in maintenance costs due to its resistance to corrosion. The successful application of carbon fiber in these major aerospace projects demonstrates its potential to revolutionize aircraft design and production, paving the way for future innovations in the industry. As aerospace engineers continue to explore advanced materials, carbon fiber is set to play a crucial role in shaping the future of air travel.

| Project Name | Application Type | Material Used (kg) | Weight Reduction (%) | Cost Improvement (%) | Performance Gain (%) |

|---|---|---|---|---|---|

| AeroCraft 1 | Fuselage Structure | 250 | 15 | 10 | 20 |

| SkyFlyer 2 | Wing Construction | 180 | 12 | 8 | 18 |

| JetStream 3 | Tail Assembly | 100 | 20 | 15 | 22 |

| AirVoyage 4 | Cockpit Frame | 75 | 10 | 5 | 10 |

| DreamGlider 5 | Landing Gear | 90 | 25 | 12 | 16 |