-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Carbon Fiber Mesh Fabric is a fascinating material that has gained popularity across various industries. Its lightweight nature and incredible strength make it an attractive choice for many applications. This fabric is engineered from woven carbon fibers, resulting in a mesh that is both flexible and durable.

One of the primary benefits of Carbon Fiber Mesh Fabric is its resistance to environmental factors. It withstands moisture, UV rays, and even chemical exposure without degrading. This makes it ideal for outdoor applications and harsh environments. However, while the material offers numerous advantages, there are still considerations to explore. The manufacturing process can be complex and costly. Additionally, not all carbon fiber meshes perform equally, leading to potential scrutiny in choosing the right type.

Overall, Carbon Fiber Mesh Fabric presents exciting possibilities. Its unique properties provide both form and function. As industries continue to innovate, the full potential of this material is yet to be realized. It's important to approach its use with both enthusiasm and caution.

Carbon fiber mesh fabric is a unique material known for its strength and lightweight properties. It is made from interwoven strands of carbon fiber, which are known for their high tensile strength. These strands create a mesh structure that allows for flexibility while maintaining durability. This composition makes carbon fiber mesh fabric suitable for various applications, including automotive, aerospace, and sports equipment.

One key benefit of carbon fiber mesh fabric is its low weight. Lightweight materials can enhance performance in applications ranging from sports gear to aircraft. This fabric also exhibits excellent chemical resistance, making it ideal for harsh environments. Its strength-to-weight ratio beats that of many traditional materials. Thus, it can provide structural integrity without adding unnecessary weight.

Tips: Ensure you consider the specific requirements of your project when selecting fabric. Understand that the manufacturing process can impact the final quality. Choosing the right thickness and weave pattern is crucial. Additionally, be prepared for potential issues such as fraying edges or difficulty in cutting it without special tools. Reflecting on these aspects can lead to better outcomes in your projects.

Carbon fiber mesh fabric is gaining attention for its unique properties. This material is lightweight yet incredibly strong. It consists of woven fibers that provide excellent tensile strength. Reports suggest that carbon fiber can be up to five times stronger than steel but weighs significantly less. This makes it ideal for various applications.

One of its key characteristics is its resistance to environmental factors. Carbon fiber mesh is resistant to corrosion, which enhances its durability in harsh conditions. According to industry studies, this fabric can withstand temperatures ranging from -100°F to 300°F. Such versatility allows it to be used in aerospace, automotive, and construction sectors.

Another notable aspect is its flexibility. Carbon fiber mesh can easily adapt to different shapes and sizes. However, not all configurations are perfect; some may experience issues with rigidity under specific loads. This adaptability makes it valuable in innovative projects. Yet, manufacturers must carefully consider how to best utilize its properties. Balancing strength and flexibility can sometimes be challenging.

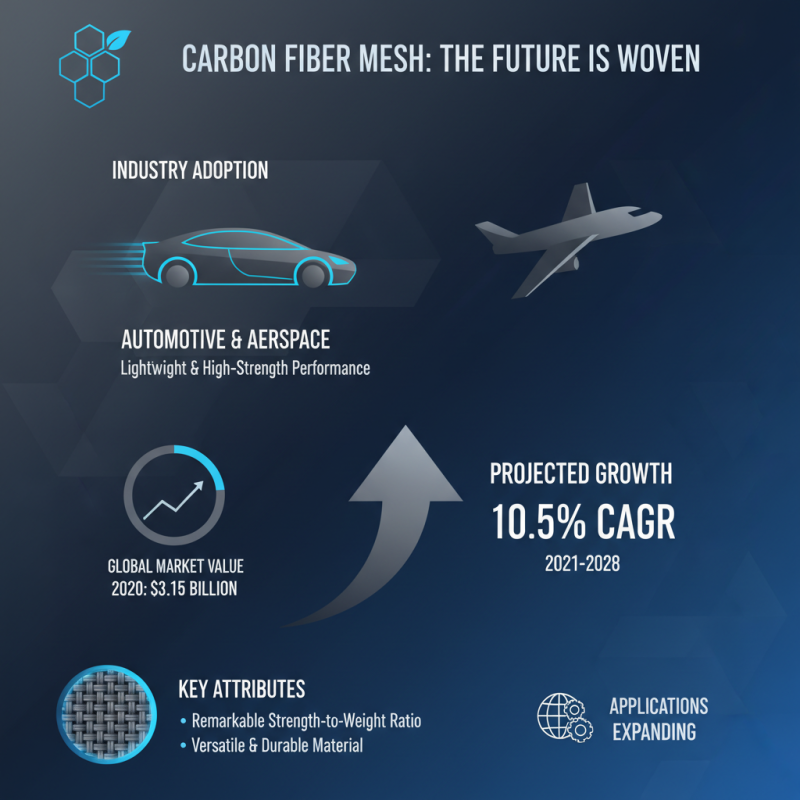

Carbon fiber mesh fabric is gaining traction across multiple industries. This lightweight material boasts a remarkable strength-to-weight ratio. It is particularly noted in automotive and aerospace sectors for its performance. The global carbon fiber market was valued at approximately $3.15 billion in 2020. This figure is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2021 to 2028.

In the construction industry, the reinforcement properties of carbon fiber mesh allow for enhanced durability in structures. It can reduce the weight of traditional materials while maintaining or improving overall strength. A study showed that carbon fiber composites can increase a building's lifespan by 20% while reducing repair costs. The construction sector has undoubtedly seen the value in these lightweight materials. However, some still question the long-term sustainability of production processes.

Moreover, in the sports industry, carbon fiber mesh is utilized in high-performance gear. It offers improved flexibility and strength, enhancing athletic performance. A report highlighted that 75% of professional athletes prefer gear made from advanced composite materials. While the benefits are clear, production emissions continue to be an area of concern. Companies are urged to explore eco-friendly alternatives to carbon fiber production to minimize environmental impact.

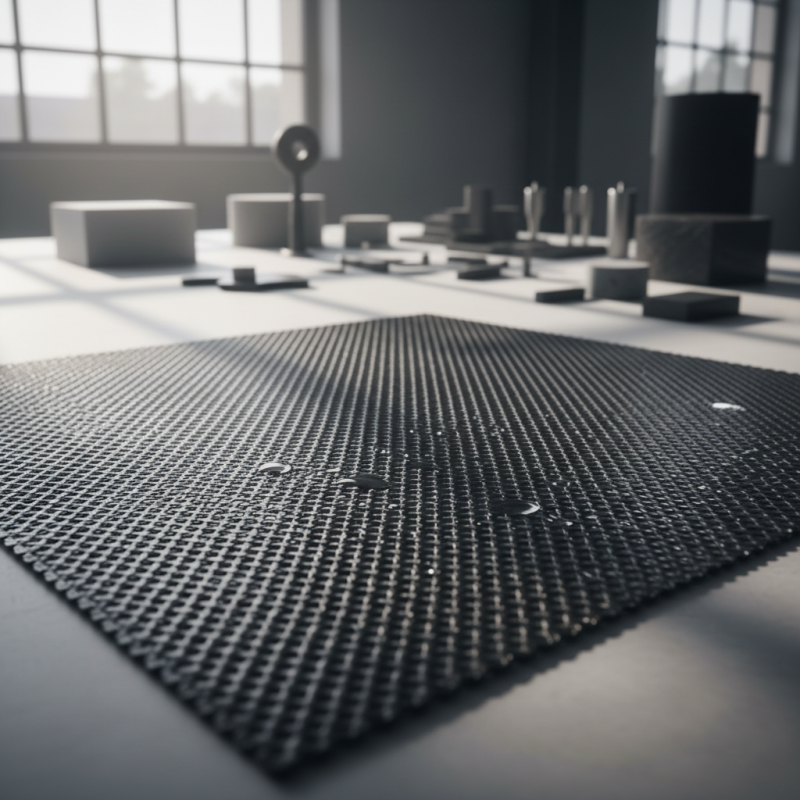

Carbon fiber mesh fabric has gained popularity in various manufacturing processes. Its lightweight nature and high strength make it an ideal choice for many applications. The fabric offers excellent durability, contributing to longer-lasting products.

One major benefit is its resistance to corrosion. Unlike metals, carbon fiber does not rust. This quality leads to reduced maintenance costs, which is attractive for manufacturers. Additionally, its flexibility allows for easy integration into different designs.

Tips: Always consider the thickness of the mesh. Thinner fabrics can be easier to work with but may lack the strength needed for certain applications. Testing is crucial to determine the best fit for your project.

The fabric can be used in aerospace, automotive, and sports industries. However, it’s essential to find the right balance between weight and strength. Overlooking this can lead to compromised product performance. Remember to adjust manufacturing techniques accordingly. Obtaining the right equipment can also be challenging but necessary for optimal results.

| Property | Details |

|---|---|

| Weight | Lightweight and strong, with a density of about 1.6 g/cm³ |

| Strength | High tensile strength, several times stronger than steel |

| Corrosion Resistance | Resistant to various environmental factors, making it durable |

| Thermal Conductivity | Low thermal expansion and effective thermal performance |

| Flexibility | Can be woven into various forms and applications easily |

| Applications | Used in aerospace, automotive, sports equipment, and construction |

| Sustainability | Can be recycled and reused, promoting environmental sustainability |

Carbon fiber mesh fabric has gained traction in various industries, highlighted by its unique properties. Unlike traditional fabrics, carbon fiber mesh is lightweight yet incredibly strong. Reports indicate that carbon fiber fabric can be five times stronger than steel while being 70% lighter. This makes it ideal for applications where weight reduction is crucial, such as in aerospace and automotive sectors.

In contrast, traditional fabrics often lack the durability and strength found in carbon fiber mesh. While cotton and polyester provide comfort, they do not offer the same structural support. A study from the Textile Research Journal noted that carbon fiber mesh showed a tensile strength of approximately 6000 MPa. This starkly contrasts with typical woven fabrics, which hit around 300 MPa at best. The challenge comes with costs; carbon fiber can be more expensive to produce than cotton due to its complex manufacturing process.

Despite its advantages, carbon fiber mesh faces challenges, particularly in terms of flexibility. It can be stiff, limiting its use in certain apparel designs. Additionally, the sustainability of carbon fiber production has been a concern. This calls for a deeper examination of its long-term impact on the environment, a factor that traditional fabrics like cotton or hemp usually satisfy better. As industries evolve, striking the right balance between innovation and sustainability will be key.

This chart compares the weight of Carbon Fiber Mesh Fabric with traditional fabrics such as Cotton, Polyester, and Nylon. As shown, Carbon Fiber Mesh is relatively lightweight, making it advantageous for applications requiring strength without bulk.