-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

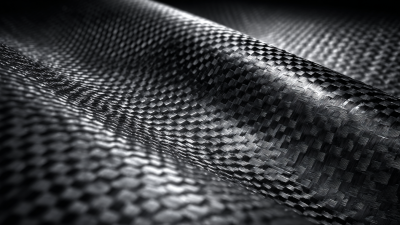

In recent years, the demand for advanced materials in various industries has surged, with a significant shift towards lightweight and durable options that can enhance performance and efficiency. Among these materials, Carbon Fiber Sheet has emerged as a frontrunner due to its unique properties, making it a popular choice in aerospace, automotive, and sporting goods sectors. According to a report by MarketsandMarkets, the global carbon fiber market is projected to reach $5.5 billion by 2025, driven by its superior strength-to-weight ratio and resistance to corrosion compared to traditional materials like steel and aluminum. As engineers and designers seek to innovate and improve their products, understanding the true advantages of Carbon Fiber Sheet over conventional materials becomes crucial. This tutorial will delve into the distinctive benefits of Carbon Fiber Sheet, shedding light on why it is increasingly favored in modern manufacturing and design processes.

The use of carbon fiber sheets as an alternative to traditional materials like concrete and steel offers remarkable advantages, particularly in the context of sustainability and performance. Conventional materials are notorious for their significant carbon emissions during production and use in civil engineering, contributing to environmental degradation. In contrast, carbon fiber exhibits an impressive balance of strength, flexibility, and lightweight properties, which can lead to reductions in material mass and consequently lower carbon footprints.

Recent trends in sustainable building materials highlight innovations that further enhance the performance of carbon fiber composites. Bioresin-based composites reinforced with natural fibers alongside carbon fiber demonstrate not only mechanical robustness but also environmental benefits when compared to traditional materials. As research delves into advanced manufacturing techniques, such as the Convergent Flow-induced Discontinuous Fiber Aligned Placement method, the potential for carbon fibers to be produced in more eco-efficient ways continues to evolve. This shift toward sustainable practices emphasizes the growing preference for innovative materials that meet the increasing demand for efficient, high-performance solutions in construction and engineering.

When comparing carbon fiber sheets to traditional materials such as steel and aluminum, several key properties set carbon fiber apart that reinforce its growing preference in various industries. Carbon fiber's high strength-to-weight ratio is one of its most impressive characteristics; it is five times stronger than steel yet significantly lighter. A study from the Composites Manufacturing Association indicates that the use of carbon fiber can reduce weight in vehicles by up to 60%, resulting in improved fuel efficiency and performance.

Another distinct advantage is its resistance to corrosion and fatigue. Unlike metals, which can rust or degrade over time, carbon fiber is impervious to moisture and chemical exposure, making it ideal for aerospace and marine applications where durability is paramount. According to research published by the American Institute of Aeronautics and Astronautics, components made from carbon fiber-reinforced polymers can last up to 40% longer than those made of conventional materials under similar stress conditions. This longevity not only enhances performance but also lowers maintenance costs and extends product lifespans, illustrating why industries are increasingly adopting carbon fiber over traditional options.

Carbon fiber has rapidly transformed various industries, showcasing its remarkable versatility and performance benefits compared to traditional materials. In the automotive sector, manufacturers are increasingly utilizing carbon fiber to reduce vehicle weight, thereby improving fuel efficiency and overall performance. For instance, high-end sports cars like the Porsche 911 GT3 incorporate carbon fiber components to achieve a perfect balance between strength and agility, allowing for enhanced speed and handling.

In the aerospace industry, carbon fiber has become the material of choice for aircraft structures, thanks to its superior strength-to-weight ratio. The Boeing 787 Dreamliner prominently features carbon fiber-reinforced polymer in its wings and fuselage, significantly reducing weight and improving fuel efficiency. This application not only demonstrates carbon fiber’s robust nature but also its ability to withstand harsh environmental conditions, making it an ideal candidate for modern aviation demands. Such real-world examples highlight the substantial advantages of carbon fiber over traditional materials, paving the way for innovation across diverse sectors.

| Material Type | Weight (kg/m²) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|

| Carbon Fiber | 1.6 | 3500 | 5.5 | Aerospace, Automotive, Sports Equipment |

| Aluminum | 2.7 | 310 | 205 | Construction, Transportation, Packaging |

| Steel | 7.85 | 400 | 50 | Construction, Manufacturing, Automotive |

| Fiberglass | 2.5 | 700 | 0.04 | Boats, Insulation, Automotive |

When evaluating the investment in carbon fiber sheets compared to traditional materials, the cost-benefit analysis reveals compelling advantages that are hard to overlook. According to a market report by Research and Markets, the global carbon fiber market is expected to reach $5.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 9.5%. This growth is primarily due to the unique properties of carbon fiber, which include an impressive strength-to-weight ratio and superior resistance to harsh environmental conditions.

In practical applications, the long-term financial benefits of carbon fiber sheets can offset their initial higher cost. A study published in the Journal of Composite Materials highlights that while carbon fiber can be up to five times more expensive than traditional materials like aluminum or steel, its lightweight nature enhances fuel efficiency in automotive and aerospace applications. For example, reducing vehicle weight by just 10% can lead to a 5-7% improvement in fuel economy. Consequently, industries adopting carbon fiber technology have reported significant reductions in operating costs, making the investment not only justifiable but also beneficial in the long run.

As industries continue to evolve, the shift towards carbon fiber in manufacturing is increasingly apparent. This high-performance material offers several advantages over traditional materials like steel and aluminum, including a remarkable strength-to-weight ratio and excellent resistance to corrosion. These attributes not only enhance product durability but also improve energy efficiency in various applications, making carbon fiber an appealing choice for sectors ranging from aerospace to automotive.

The growing adoption of carbon fiber signifies a broader trend towards lightweighting and sustainability in manufacturing. Companies are recognizing that by incorporating carbon fiber into their production processes, they can reduce overall weight, leading to lower fuel consumption in vehicles and reduced emissions.

Furthermore, advancements in production technologies are making carbon fiber more accessible and cost-effective, paving the way for its use in more mainstream applications. As manufacturers continue to embrace these innovations, we can expect carbon fiber to play a pivotal role in shaping the future of industrial design and engineering.