-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the Carbon Fiber Tube has gained significant attention across various industries due to its remarkable properties and versatility. Made from woven strands of carbon fibers, these tubes offer an exceptional strength-to-weight ratio, making them ideal for applications where lightweight materials are crucial without compromising on performance. The unique composition of carbon fibers enhances durability, resistance to corrosion, and thermal stability, further expanding their usability in demanding environments.

From aerospace and automotive sectors to sports and recreational equipment, Carbon Fiber Tubes have become integral components in modern engineering and design. Their application ranges from structural components in aircraft and high-performance vehicles to lightweight frameworks in bicycles and sports gear. The increasing focus on energy efficiency and sustainability in manufacturing has prompted further exploration into carbon fiber technology, paving the way for innovative solutions that meet the needs of various industries while minimizing environmental impact.

As the demand for high-performance materials continues to rise, understanding the characteristics and applications of Carbon Fiber Tubes becomes essential for engineers and designers. This article delves into the composition, benefits, and widespread uses of these tubes, highlighting their pivotal role in shaping the future of multiple industries.

Carbon fiber tubes are composite materials primarily made from strands of carbon fibers woven together and embedded in a resin matrix. The carbon fibers account for the majority of the tube's strength and rigidity, while the resin binds the fibers together, providing structural integrity. The manufacturing process may involve techniques such as filament winding, pultrusion, or resin infusion, which contribute to the lightweight yet robust characteristics of the final product.

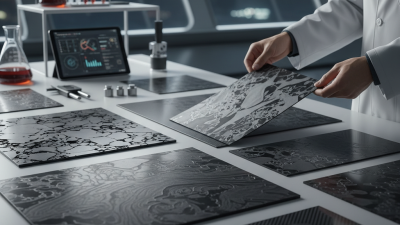

These tubes exhibit excellent mechanical properties, including high tensile strength, low weight, and resistance to environmental factors such as corrosion and UV radiation. As a result, carbon fiber tubes are widely utilized in various industries, including aerospace, automotive, marine, sports equipment, and construction. Their adaptability allows for innovative applications, such as lightweight frameworks in vehicles and cutting-edge components in sporting goods.

Tip: When working with carbon fiber tubes, ensure you use appropriate protective gear, as the fibers can cause skin irritation. Additionally, consider the specific requirements of your application, including load-bearing needs and environmental exposure, to select the right type of carbon fiber tube for optimal performance.

Carbon fiber tubes are manufactured through several intricate processes that leverage the unique properties of carbon fibers. The primary method involves the winding of carbon fiber strands around a mandrel. This process, known as filament winding, allows for the creation of composite structures with high strength-to-weight ratios. By precisely controlling the orientation of the fibers, manufacturers can enhance the mechanical properties of the tubes, making them suitable for demanding applications across various industries.

Another widely used technique is the pultrusion process, where carbon fibers are drawn through a resin bath and then through a heated die to create a continuous profile. This method ensures uniformity and excellent structural integrity throughout the length of the tube. In addition, techniques such as autoclave curing can be employed to further enhance the bonding of the resin matrix with the carbon fibers, resulting in superior performance characteristics. These manufacturing methods create a versatile range of carbon fiber tubes that serve critical roles in aerospace, automotive, sporting goods, and medical industries, where lightweight and strong materials are paramount.

Carbon fiber tubes are increasingly becoming an essential component in the aerospace industry due to their remarkable strength-to-weight ratio. These tubes are engineered from carbon fibers woven together and surrounded by a resin matrix, providing robust structural support while being significantly lighter than traditional metals. This characteristic makes them ideal for applications in aircraft components, where reducing weight can lead to improved fuel efficiency and performance.

In aerospace applications, carbon fiber tubes are often utilized in the construction of fuselage sections, wing spars, and landing gear. Their stiffness ensures structural integrity during demanding conditions, while also allowing for greater design flexibility in optimizing aerodynamics. The high fatigue resistance and endurance in extreme temperatures further enhance their utility in high-performance aircraft and spacecraft.

**Tips:** When considering the implementation of carbon fiber tubes in aerospace designs, ensure that the specific properties of the carbon fiber are matched to the required performance criteria of the application. It's also vital to conduct thorough testing, as even minor variations in tube composition can affect overall aircraft safety and efficiency. Always keep abreast of the latest advancements in carbon fiber technology to stay ahead in application capabilities.

Carbon fiber tubes have gained significant traction in the automotive sector due to their remarkable strength-to-weight ratio and high stiffness, making them ideal for various applications. According to a report by Markets and Markets, the global carbon fiber market in the automotive industry is projected to reach USD 3.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 15.4% from 2020. This growth is driven primarily by the increasing demand for lightweight materials to improve fuel efficiency and meet stringent emission regulations.

One of the most notable uses of carbon fiber tubes in the automotive sector is in chassis and structural components. These tubes not only reduce overall vehicle weight but also enhance structural integrity, which is essential for safety and performance. Additionally, carbon fiber composite materials are increasingly used in the production of crash-resistant panels, which protect vehicle occupants without adding excessive weight. According to the Carbon Fiber Composites Association, replacing traditional steel components with carbon fiber-based alternatives can lead to weight reductions of up to 50%, significantly improving vehicle dynamics and reducing energy consumption.

Furthermore, the integration of carbon fiber tubes in electric vehicles (EVs) is particularly advantageous, as the weight savings can lead to extended driving range and improved battery efficiency. As automotive manufacturers continue to invest in carbon fiber technologies, the shift towards more sustainable and efficient vehicles is expected to accelerate, solidifying carbon fiber's role as a key material in the future of the automotive industry.

Carbon fiber tubes have gained significant traction across various industries due to their unique combination of strength and lightweight properties. One of the primary benefits of carbon fiber tubes is their impressive strength-to-weight ratio, which is estimated to be five times that of steel. This makes them particularly advantageous in sectors such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. According to a recent industry report from Market Research Future, the aerospace carbon fiber composites market is expected to reach a valuation of over $30 billion by 2025, highlighting the increasing reliance on carbon fiber materials to enhance structural integrity while minimizing weight.

However, while the advantages of carbon fiber tubes are clear, there are limitations that industries must consider. The production costs for carbon fiber materials remain significantly higher than those of conventional materials like aluminum or plastic. As of 2023, the average price of carbon fiber is reported to be between $15 to $20 per pound, compared to aluminum, which ranges around $1.00 per pound. This economic factor can hinder widespread adoption, especially in industries that require cost-effective solutions. Additionally, carbon fiber's susceptibility to impact damage and challenges in recycling processes pose challenges that further complicate its use. Therefore, while the benefits of carbon fiber tubes are substantial, industries must carefully weigh these limitations against their specific application needs.