-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Carbon Fibre Mesh is a cutting-edge material that has gained significant attention in various industries due to its unique properties and versatility. Composed of interwoven strands of carbon fibre, this lightweight yet remarkably strong mesh offers a range of benefits that make it an ideal choice for modern applications. From aerospace and automotive engineering to sports equipment and civil construction, the exceptional strength-to-weight ratio of Carbon Fibre Mesh allows for innovative designs and improved performance, setting new standards across multiple fields.

The utilization of Carbon Fibre Mesh has revolutionized traditional manufacturing processes, enabling the development of products that are not only lightweight but also durable and resistant to corrosion. Its adaptability in design means it can be tailored to meet specific requirements, such as flexibility, support, or structural integrity. As industries continue to seek sustainable and efficient solutions, the role of Carbon Fibre Mesh becomes increasingly vital, paving the way for advancements that enhance efficiency and reduce environmental impact. Thus, understanding the characteristics and applications of Carbon Fibre Mesh is essential for appreciating its contribution to the modern technological landscape.

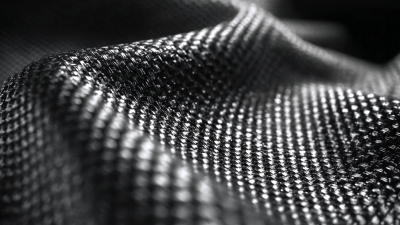

Carbon fibre mesh is a versatile material composed of interwoven carbon fibres, known for its exceptional strength-to-weight ratio and durability. This mesh typically consists of multiple layers of carbon fibres that are combined through a resin matrix, forming a lightweight yet sturdy framework. The inherent properties of carbon fibre—such as high tensile strength and resistance to chemical corrosion—make it a popular choice in various modern applications.

One of the primary uses of carbon fibre mesh is in the construction industry, where it serves as a reinforcement material for concrete structures. By integrating this mesh into concrete, builders can significantly enhance the tensile strength and overall stability of buildings and infrastructure, allowing for more innovative designs and reducing the risk of structural failure. Additionally, carbon fibre mesh is widely utilized in the automotive and aerospace industries, where weight reduction is critical. It contributes to the production of lightweight components that improve fuel efficiency without compromising performance or safety. Its unique properties also enable carbon fibre mesh to be used in the production of sporting goods, medical equipment, and protective gear, showcasing its versatility across diverse fields.

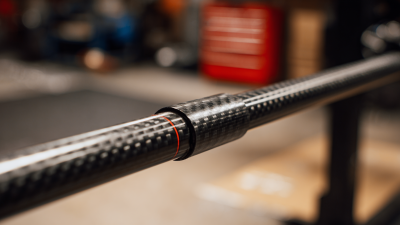

Carbon fibre mesh is an advanced composite material known for its remarkable strength-to-weight ratio and versatility in modern applications. The composition of carbon fibre mesh primarily consists of carbon fibres, which are created from polyacrylonitrile (PAN) or petroleum pitch through a process of oxidation and carbonization. The fibres are then woven together in a grid-like structure, forming a lightweight mesh that maintains high tensile strength and rigidity. This unique composition allows the mesh to distribute loads efficiently, making it an ideal choice for reinforcing various materials.

The structure of carbon fibre mesh is characterized by its interwoven pattern, which enhances its durability and flexibility. The individual strands of carbon fibres are incredibly thin yet possess a high degree of stiffness. When combined in a mesh format, they create a composite that can withstand significant stress without deforming. This structural integrity makes carbon fibre mesh suitable for applications in construction, automotive, and aerospace industries, where lightweight yet sturdy materials are essential. Additionally, the mesh can be easily molded and saturated with resins or polymers, further increasing its functionality in creating composite materials that benefit from both strength and lightweight properties.

| Application | Material Composition | Properties | Usage |

|---|---|---|---|

| Aerospace Components | Carbon fibers woven into mesh, epoxy resin | Lightweight, high tensile strength, corrosion-resistant | Used in aircraft structures and components |

| Automotive Parts | Carbon fiber woven into fabric, resin | Durable, lightweight, good shock absorption | Engine covers, body panels |

| Sporting Goods | Carbon fiber mat, thermosetting resin | High strength-to-weight ratio, stiffness | Bikes, golf clubs, tennis rackets |

| Construction Reinforcement | Carbon fiber strands, polymer matrix | High durability, flexible, lightweight | Reinforcing beams, floors, ceilings |

| Consumer Electronics | Carbon fiber skins, resin | Lightweight, aesthetic appeal, strong | Phone cases, laptop shells |

Carbon fibre mesh is increasingly becoming a preferred material across various industries due to its impressive strength-to-weight ratio, durability, and versatility. The lightweight nature of carbon fibre makes it ideal for applications that require strength without the added mass, such as in the aerospace and automotive sectors. This material allows manufacturers to create structures that can withstand high levels of stress and strain while improving fuel efficiency by reducing overall weight.

In construction and civil engineering, carbon fibre mesh is utilized for reinforcing concrete structures. Its resistance to corrosion and environmental damage ensures longevity and lowers maintenance costs. Furthermore, the ability to easily mold and manipulate carbon fibre mesh expands its applications to intricate designs and integration into existing infrastructure. The healthcare industry also benefits from carbon fibre’s properties, using it in medical devices and prosthetics for their strength and lightweight characteristics, thereby enhancing patient comfort and mobility. These advantages highlight the growing importance of carbon fibre mesh as a transformative material across multiple sectors.

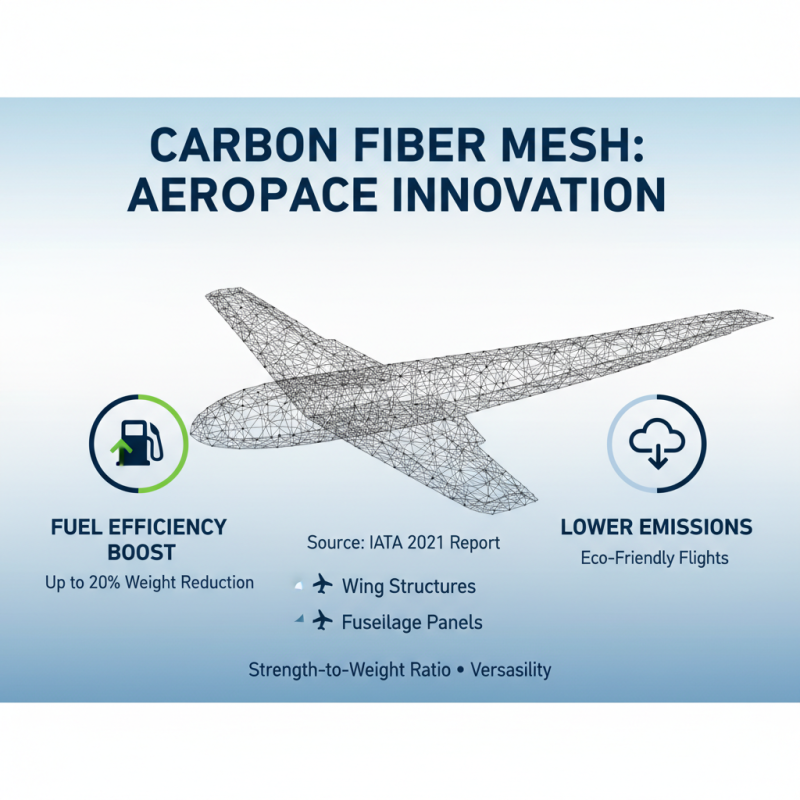

Carbon fibre mesh has emerged as a critical component in various modern technologies, thanks to its exceptional strength-to-weight ratio and versatility. One of the primary applications of carbon fibre mesh is in the aerospace sector, where weight reduction is crucial for improving fuel efficiency. According to a 2021 report from the International Air Transport Association (IATA), lightweight materials like carbon fibre composites can reduce aircraft weight by up to 20%, leading to significant fuel savings and lower emissions. This makes carbon fibre mesh an essential element in the construction of aircraft components, such as wing structures and fuselage panels.

In the automotive industry, carbon fibre mesh is increasingly utilized to enhance vehicle performance and safety. A study by MarketsandMarkets forecasts that the carbon fibre reinforced polymer market will reach $30.3 billion by 2026, driven largely by the automotive sector. Carbon fibre mesh is used in high-performance vehicles to strengthen key structural areas while maintaining a low overall weight, thus improving acceleration and handling. Additionally, its application in crash-resistant designs provides enhanced passenger safety, confirming its importance in modern automotive engineering.

Moreover, carbon fibre mesh plays a significant role in sports equipment, where performance and durability are paramount. The Global Sports Equipment Market is projected to grow at a CAGR of 5.8% from 2021 to 2026, with carbon fibre composites being a driving force behind the development of lighter and stronger athletic gear. From bicycles to professional-grade tennis rackets, the use of carbon fibre mesh ensures that athletes have the competitive edge they need while benefiting from improved comfort and efficiency.

The utilization of carbon fibre mesh in modern applications is experiencing a significant expansion, driven by innovations that enhance its properties and broaden its potential uses. Predictions from industry reports, such as those from Grand View Research, suggest that the carbon fibre market is expected to grow substantially, potentially reaching a valuation of USD 5.2 billion by 2028. This surge is predominantly attributed to its applications in aerospace, automotive, and construction sectors, where its lightweight yet strong attributes make it an invaluable material.

Future developments in carbon fibre mesh technology are likely to focus on sustainability and cost-effectiveness. Researchers are actively exploring bio-based and recycled carbon fibres to reduce the environmental impact associated with traditional carbon fibre production. The introduction of automated manufacturing processes, such as 3D weaving, is also anticipated to reduce production costs and increase the efficiency of carbon fibre mesh production. Moreover, advancements in composite materials science may lead to enhanced performance characteristics, such as improved impact resistance and flexibility, thereby expanding its applicability in sectors like sports equipment and medical devices. As these trends progress, carbon fibre mesh is set to play a crucial role in shaping future industrial innovations.