-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Choosing the right stab resistant fabric is crucial for ensuring personal safety and security in various environments. With the increasing concerns over violence and the need for protective gear, the stab-resistant fabric market is projected to grow significantly. According to a report by Research and Markets, the global market for protective clothing, which includes stab resistant materials, is expected to reach $12.78 billion by 2026, with a CAGR of 7.2% from 2021 to 2026. This emphasizes the importance of understanding different fabric technologies, their ratings and certifications, as well as their specific applications. Whether for law enforcement, security personnel, or personal defense, selecting the appropriate stab resistant fabric is not just about comfort and durability; it’s about meeting the unique demands of your particular environment and ensuring that you have the highest level of protection available.

When selecting stab resistant fabrics, several factors must be taken into account to ensure that the material meets your specific needs. First and foremost, consider the level of protection required. Fabrics are often rated based on their ability to withstand penetration from various types of knives and sharp objects. Understanding the potential threats you might face will help you choose the appropriate level of resistance.

Another critical factor is the weight and flexibility of the material. Lighter fabrics offer better mobility, making them ideal for situations where agility is crucial. However, they may compromise on protection compared to heavier, more robust materials. It’s essential to find a balance between comfort and security.

Tips: Look for fabrics that incorporate multiple layers or advanced materials such as Kevlar or Dyneema, which are known for their strength-to-weight ratio. Additionally, trialing the fabric in real-life scenarios can provide insight into its performance, ensuring that it meets your expectations in both comfort and resilience.

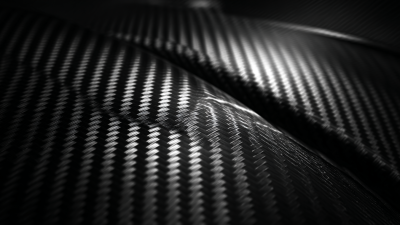

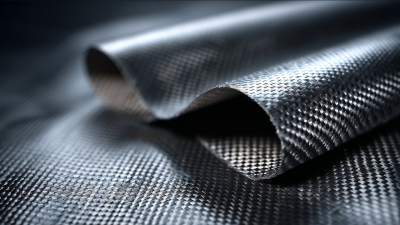

When selecting the right stab-resistant fabric, understanding the various types of stab-resistant materials is crucial. Commonly used materials include Kevlar, Dyneema, and other proprietary blends designed for strength and flexibility. Kevlar, known for its high tensile strength and lightweight properties, is widely utilized in law enforcement gear. According to a report by the National Institute of Justice, Kevlar can provide up to 75% more protection against stabbing threats compared to traditional fabrics, making it a favored choice for personal protective equipment.

Dyneema, another advanced material, offers an exceptional strength-to-weight ratio and superior puncture resistance. Industry analyses suggest that Dyneema is up to 15 times stronger than steel by weight, which significantly enhances its effectiveness in stab-resistant applications. Additionally, new hybrid fabrics incorporating both Kevlar and Dyneema are emerging, providing improved resilience and comfort. These materials are tailored not just for durability but also to ensure maximum mobility for the wearer, essential for professionals in high-risk environments. Understanding these options helps consumers make informed decisions to meet their specific safety requirements.

When evaluating the level of protection required for your situation, it is crucial to consider the specific risks you may encounter. Different environments, whether in law enforcement, security, or personal defense, present unique threats that can dictate the type of stab-resistant fabric necessary. For instance, professionals working in high-risk areas might need materials tested against higher levels of puncture resistance, while those in less threatening environments might opt for lighter and more flexible options.

Additionally, understanding the standards and certifications associated with stab-resistant fabrics can guide your decision. Fabrics are often rated based on their ability to withstand specific types of attacks, with higher ratings indicating greater protection. It's important to match these ratings with the potential threats in your surroundings. Ultimately, taking the time to assess both the nature of your environment and the corresponding protective standards will ensure that you select a fabric that meets your needs effectively.

When selecting stab resistant fabrics, it is essential to pay attention to testing and certifications to ensure you are getting a quality product that meets safety standards. One of the primary certifications to consider is the NIJ (National Institute of Justice) rating, which assesses the performance of body armor, including stab-resistant materials. Fabrics that pass the NIJ testing indicate that they can effectively resist knife attacks and other sharp objects, giving you peace of mind.

When selecting stab resistant fabrics, it is essential to pay attention to testing and certifications to ensure you are getting a quality product that meets safety standards. One of the primary certifications to consider is the NIJ (National Institute of Justice) rating, which assesses the performance of body armor, including stab-resistant materials. Fabrics that pass the NIJ testing indicate that they can effectively resist knife attacks and other sharp objects, giving you peace of mind.

In addition to NIJ standards, look for fabrics tested for specific properties like puncture resistance and cut resistance. ASTM (American Society for Testing and Materials) standards are also critical, as they provide a benchmark for measuring the fabric's ability to withstand stabbing threats. Certifications from recognized entities not only reflect the fabric's reliability but also help you compare different options effectively. By focusing on these testing and certifications, you can choose a stab resistant fabric that aligns with your specific needs, ensuring optimal protection.

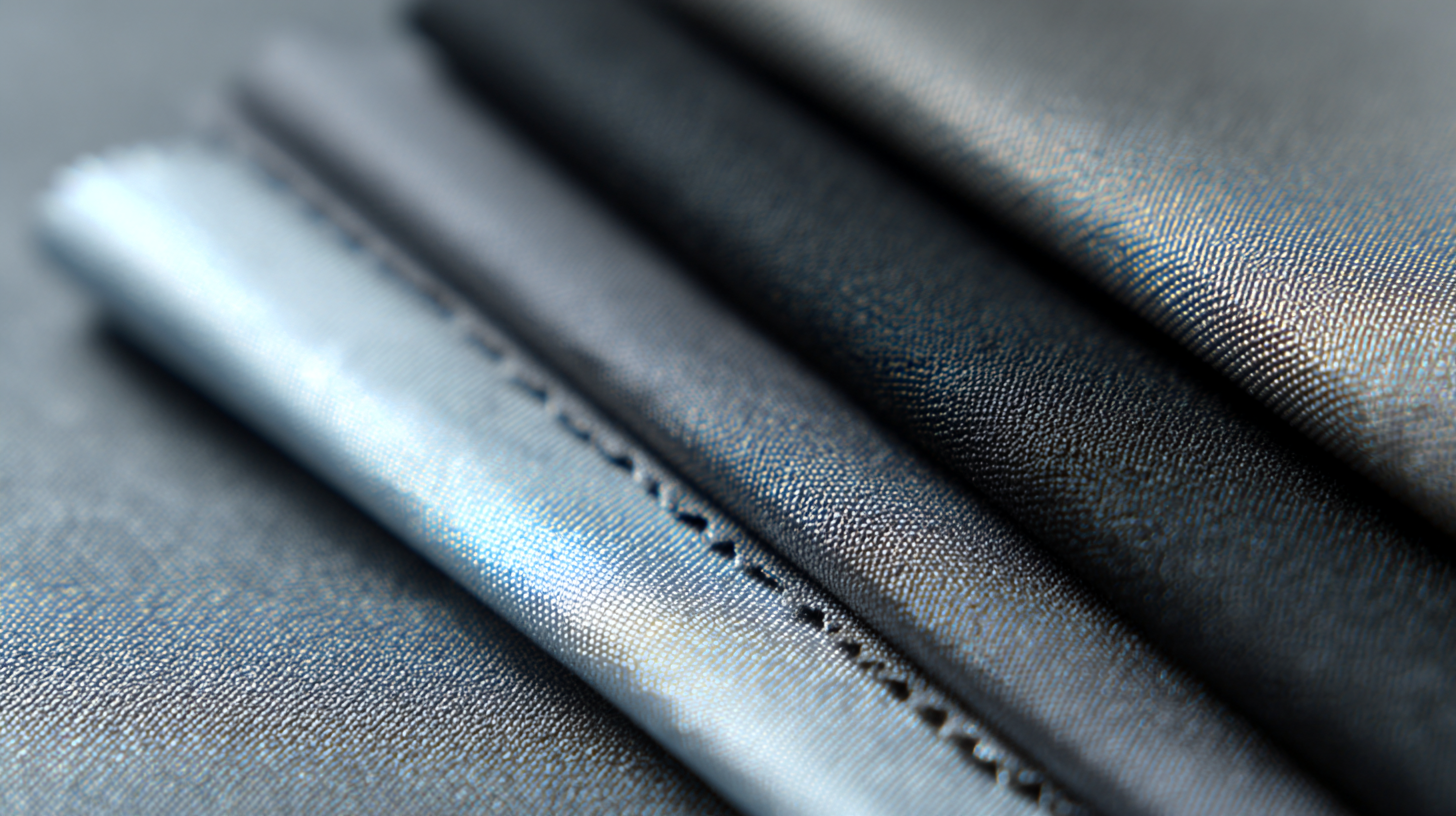

When selecting stab-resistant fabric, understanding the balance between cost and performance is crucial. According to a report by the National Institute of Justice, stab-resistant materials vary significantly in price, influenced by factors such as material composition, weave technology, and treatment processes. For instance, high-performance aramid fibers, while more expensive, offer superior protection against sharp objects, making them a popular choice in law enforcement and correctional facilities.

Additionally, the performance capabilities of different fabrics can vary even within similar price ranges. Fabrics like polyethylene blends can provide a good balance of affordability and effectiveness but may not be suitable for high-risk environments. Depending on the application, it may be wise to invest a bit more for materials specifically engineered to withstand high-pressure situations, as the costs related to injury and liability can far exceed the initial investment in better fabric.

Tips: When assessing stab-resistant fabric, consider not only the upfront cost but also the long-term benefits of durability and protective capabilities. Always consult industry standards, such as those outlined by the American National Standards Institute (ANSI), to ensure you are choosing a fabric that meets your specific safety needs. Testing samples in real-world scenarios can also provide vital insights into their performance before making a commitment.

| Fabric Type | Cost per Square Meter | Weight (g/m²) | Cut Resistance Level | Flexibility | Water Resistance |

|---|---|---|---|---|---|

| Aramid Fiber | $30 | 200 | Level A4 | High | Moderate |

| UHMWPE (Ultra-High Molecular Weight Polyethylene) | $50 | 150 | Level A5 | Very High | High |

| Steel Mesh | $40 | 300 | Level A6 | Low | No |

| Ballistic Nylon | $25 | 400 | Level A3 | Moderate | Low |

| Kevlar | $55 | 220 | Level A6 | High | Moderate |