-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the demand for Large Carbon Fiber Sheets has surged across various industries, driven by their exceptional strength-to-weight ratio and versatile applications. According to a report by MarketsandMarkets, the global carbon fiber market is expected to grow from USD 3.3 billion in 2020 to USD 5.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.5%. This growth is largely attributed to the increasing adoption of carbon fiber materials in aerospace, automotive, and sports equipment, where performance and durability are crucial.

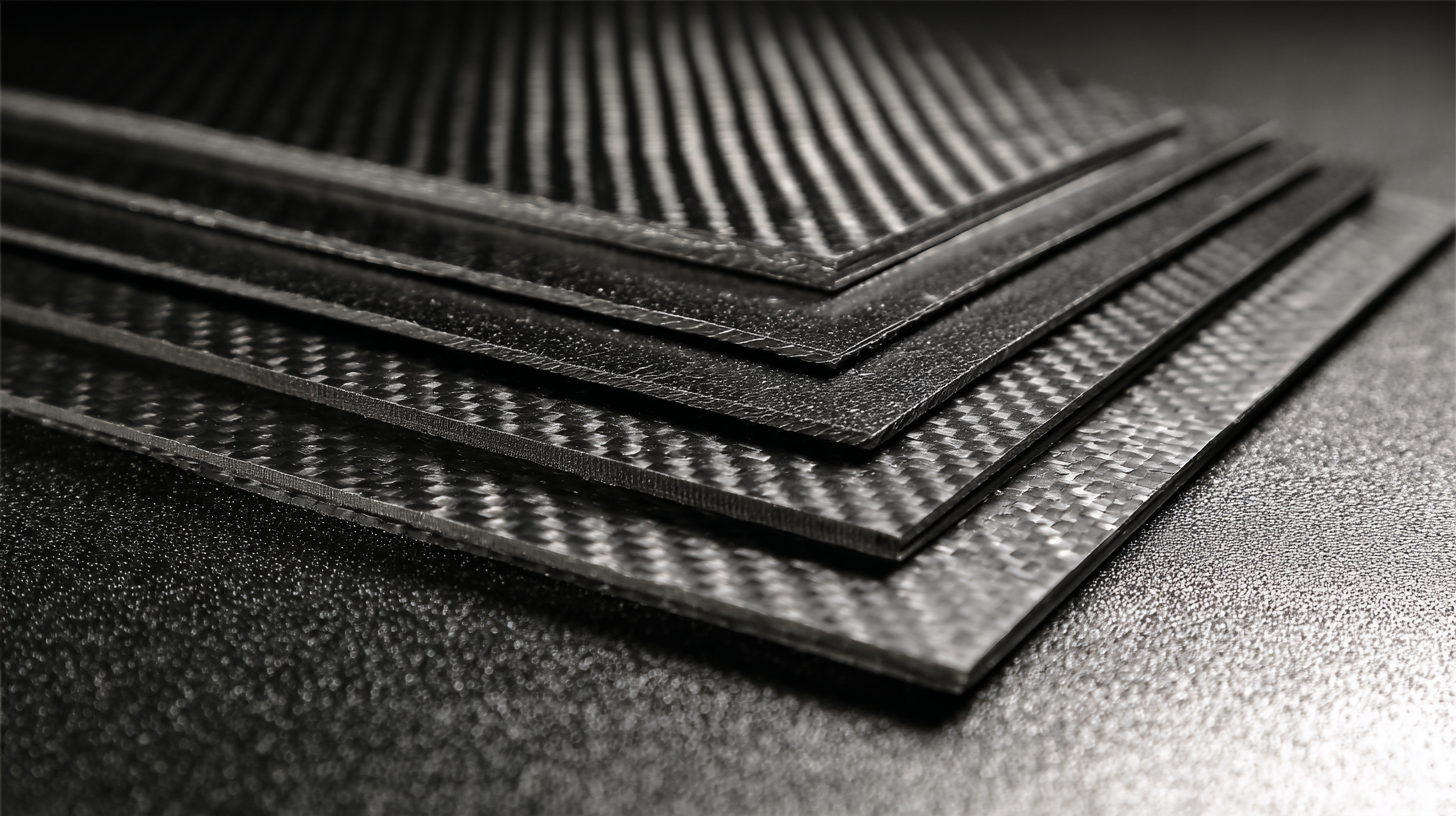

However, choosing the right Large Carbon Fiber Sheets for specific projects can be challenging due to the variety of options available. Factors such as thickness, weave pattern, and resin type can significantly impact performance and suitability. Therefore, understanding these key elements is essential for making an informed decision that aligns with project requirements and desired outcomes.

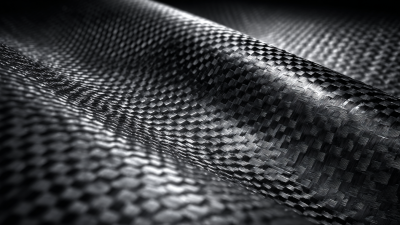

When selecting large carbon fiber sheets for your projects, understanding the specifications is crucial. Carbon fiber sheets come with a range of parameters, including thickness, weave style, and resin type. Thickness can significantly impact the weight and strength of your final product; thus, consider your project's structural demands carefully. Weave styles, such as plain, twill, or satin, not only influence the aesthetic but also the mechanical properties, so choose one that aligns with your design requirements.

Tips: Always consider the temperature resistance of the resin used in your carbon fiber sheet, especially if your project will be subjected to high heat. Additionally, examine the moisture resistance characteristics, particularly for outdoor applications, to ensure longevity and durability. Lastly, pay attention to the manufacturer’s specifications to guarantee compliance with your project needs and standards.

Additionally, understanding the different resin types, such as epoxy or polyester, can help you achieve the desired results. Epoxy resins typically offer better strength and chemical resistance, making them ideal for high-performance applications. Be mindful of the operational environment of your project, as this can dictate the kind of resin you should select for enhanced performance and longevity.

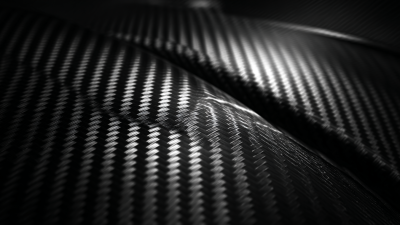

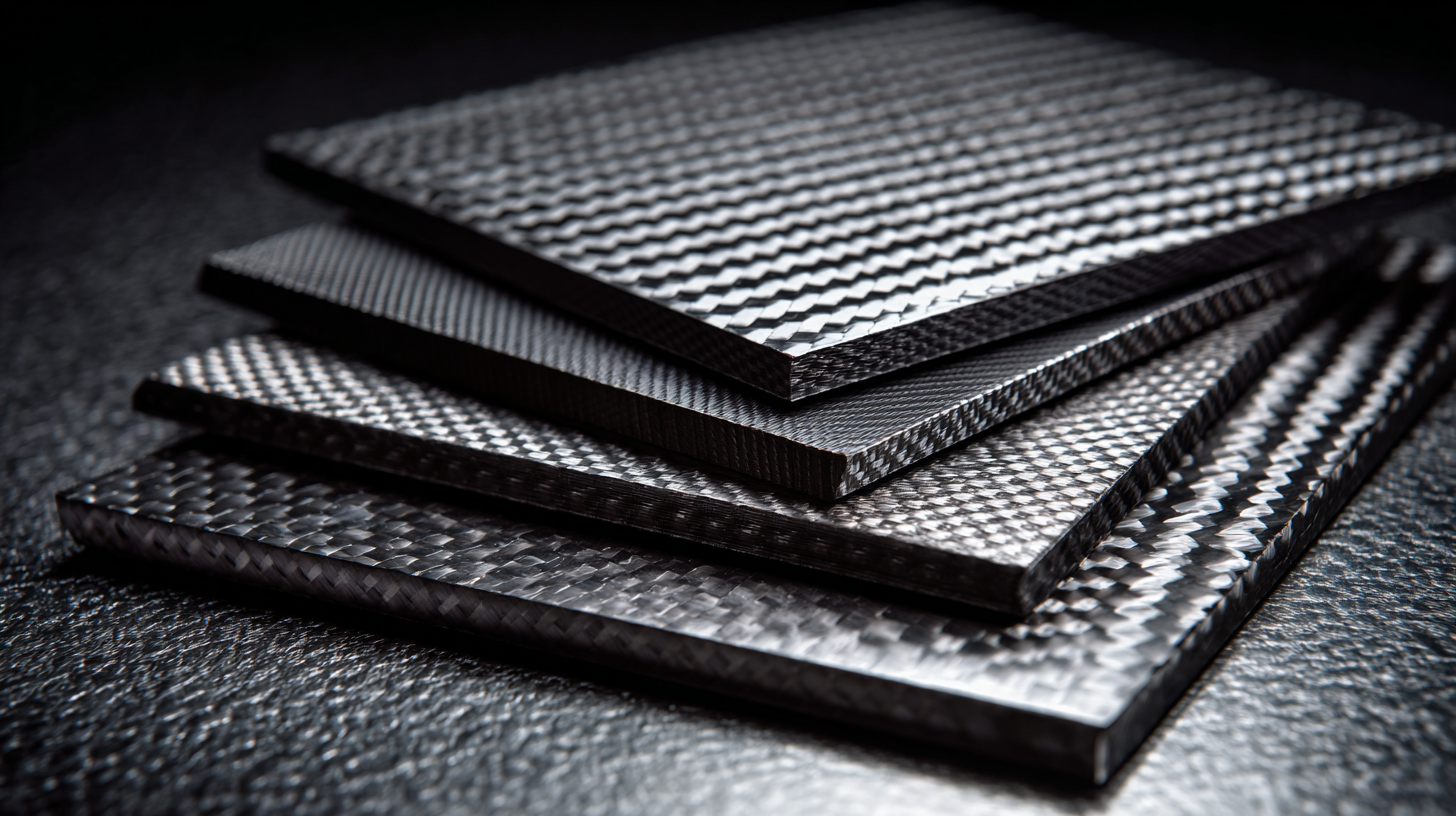

When selecting large carbon fiber sheets for your projects, one of the most critical considerations is the strength and flexibility requirements. Different applications demand varying levels of tensile strength and flexibility, which will ultimately influence the choice of materials. Projects that require high impact resistance and durability, such as in aerospace or automotive industries, necessitate sheets that can withstand significant stress without deforming. Conversely, applications that involve complex shapes or require bending may favor sheets with enhanced flexibility to avoid cracking during fabrication.

In assessing the specific needs of your project, it is essential to examine factors like load-bearing capacity and environmental conditions. For example, if the sheets will be exposed to extreme temperatures or moisture, selecting a composite that offers better thermal stability and water resistance becomes crucial. Additionally, evaluating the manufacturing process, such as whether it will involve machining or molding, will help determine the necessary properties of the carbon fiber sheets. By understanding these parameters, you can make a more informed decision that aligns with the requirements of your specific project.

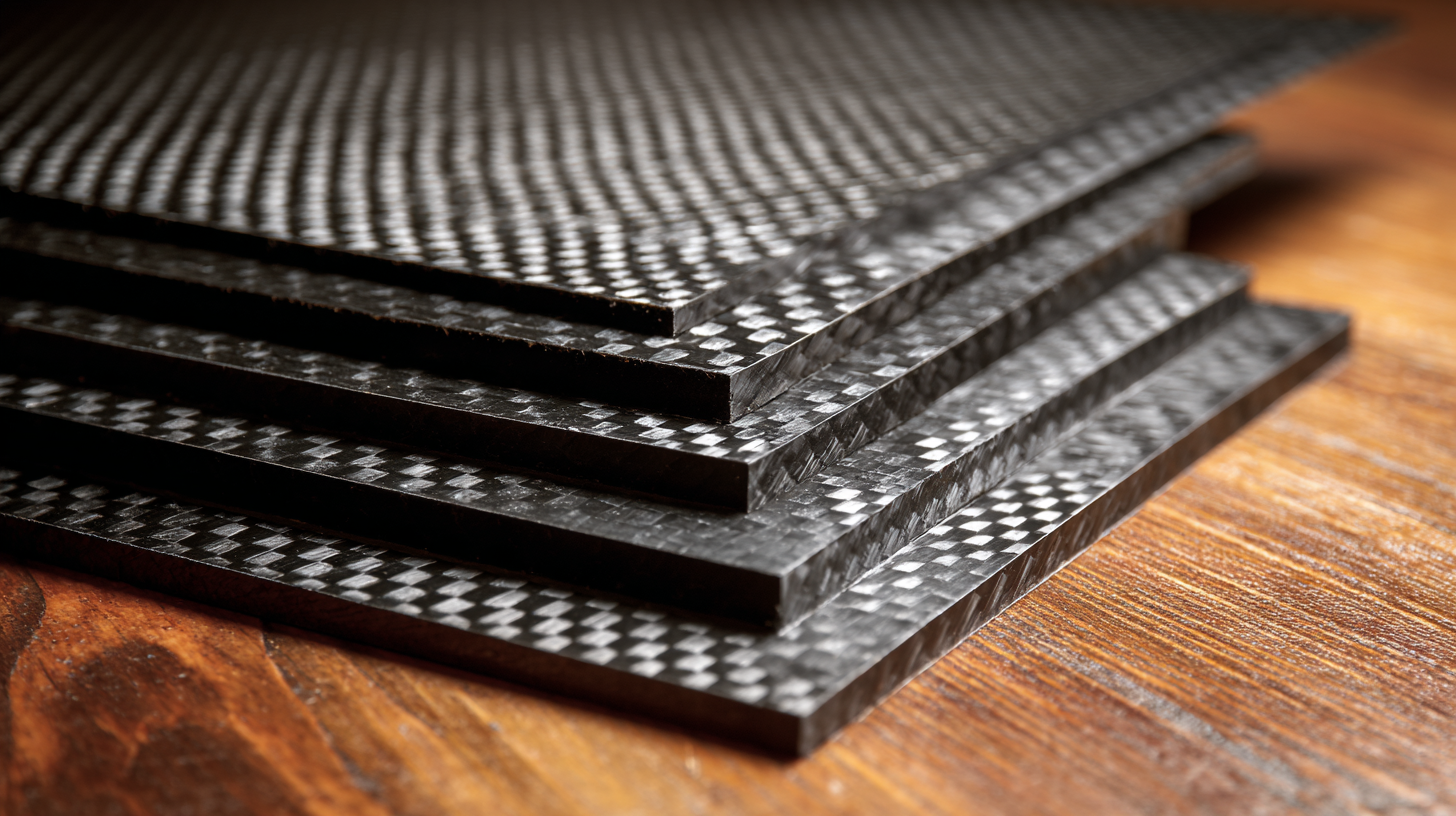

When selecting large carbon fiber sheets for various projects, understanding the importance of thickness and size is crucial. Carbon fiber properties can vary significantly based on these dimensions. According to a report by the Composites Market Research Group, the ideal thickness for carbon fiber sheets can range from 0.5 mm to 5 mm, which is influenced by the specific application. Thinner sheets, typically around 0.5 mm to 2 mm, are desirable for applications that require flexibility and lightweight characteristics, such as in automotive or aerospace designs. Conversely, thicker sheets are better suited for structural applications where rigidity and strength are paramount.

Size also plays a critical role in performance and usability. The industry standard for large carbon fiber sheets tends to be 4 ft by 8 ft, as noted in a 2022 market analysis by the American Composites Manufacturers Association. However, custom sizes are available and can provide more versatility for unique project requirements. Understanding the balance between thickness and size not only ensures optimal structural integrity but also affects the overall performance and longevity of the finished product. By considering these factors, designers and engineers can make more informed decisions that align with their project goals.

When selecting large carbon fiber sheets for your projects, evaluating the cost versus performance is crucial to making an informed decision. Carbon fiber is renowned for its exceptional strength-to-weight ratio, durability, and resistance to various environmental conditions. However, prices can vary significantly based on the quality, type of weave, and production methods. Higher-quality materials often offer better performance in terms of tensile strength and impact resistance, which can be critical depending on your application, whether it’s aerospace, automotive, or sporting goods.

Before committing to a purchase, it's essential to assess the specific requirements of your project. Consider how the performance characteristics of different types of carbon fiber sheets align with your expectations. For instance, if your project demands high stiffness and low weight, investing in a premium-grade sheet may be worthwhile despite the higher upfront cost. On the other hand, for applications where performance is not as critical, opting for a mid-range product could result in significant cost savings while still meeting your functional needs. Balancing these factors will enable you to select the appropriate material that meets performance standards without overspending.

When sourcing high-quality carbon fiber sheets for your projects, it is crucial to identify reliable suppliers who can meet your specific needs. Start by researching manufacturers with a solid reputation in the industry. Look for companies that have been in business for a significant amount of time and possess favorable reviews from previous clients. Engaging with other professionals in your field can also yield valuable recommendations and insights into supplier performance.

Additionally, consider the quality standards and certifications that the suppliers adhere to. A reputable supplier should provide clear indications of their product quality through certifications such as ISO standards or specifications that meet industry requirements. Don’t hesitate to request sample sheets to assess their properties like tensile strength, stiffness, and weight. By doing thorough due diligence and choosing a supplier that prioritizes quality, you can ensure your projects benefit from the superior performance of carbon fiber materials.

| Dimension (mm) | Thickness (mm) | Weight (kg/m2) | Tensile Strength (MPa) | Supplier Rating (out of 5) |

|---|---|---|---|---|

| 3000 x 1500 | 2 | 3.5 | 600 | 4.8 |

| 2500 x 1250 | 3 | 5.0 | 700 | 4.5 |

| 4000 x 2000 | 5 | 6.8 | 800 | 5.0 |

| 5000 x 2500 | 4 | 6.0 | 700 | 4.7 |