-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the demand for Large Carbon Fiber Sheets has surged across various industries, particularly in aerospace, automotive, and sports equipment, due to their exceptional strength-to-weight ratio and versatility. According to a report by Research and Markets, the global carbon fiber market is projected to reach USD 5.5 billion by 2026, growing at a CAGR of 10.6% from 2021 to 2026. This growth highlights the increasing reliance on carbon fiber materials to enhance performance and efficiency in manufacturing processes. However, choosing the best Large Carbon Fiber Sheets for your project needs can be a daunting task, as factors such as thickness, resin type, and manufacturing method significantly impact the material's performance. Understanding these key elements is crucial for engineers and designers looking to leverage the advantages of carbon fiber in their projects.

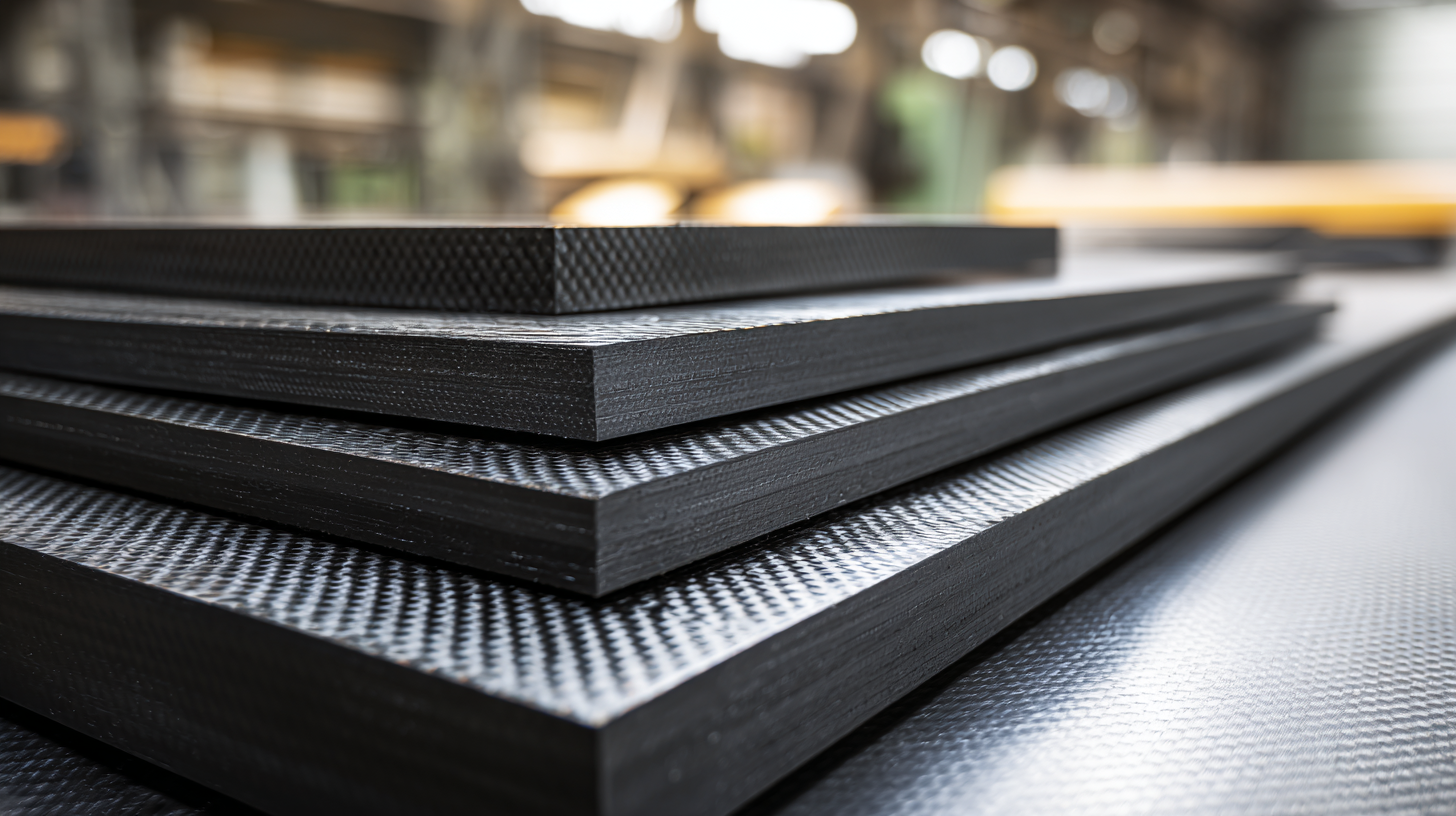

When embarking on a project requiring large carbon fiber sheets, understanding their specifications is crucial. Carbon fiber sheets come in various thicknesses, widths, and lengths, making it essential to select the right dimensions for your specific needs. For example, thicker sheets offer greater rigidity and strength, which is ideal for structural applications, while thinner sheets provide flexibility, suited for intricate designs.

Tip: Always assess the load-bearing requirements of your project before deciding on sheet thickness. This ensures that the selected sheet can withstand the necessary stresses without compromising integrity.

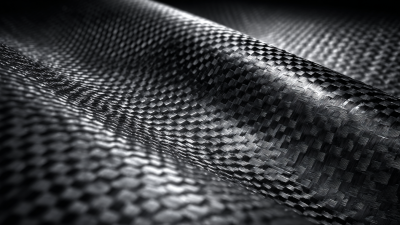

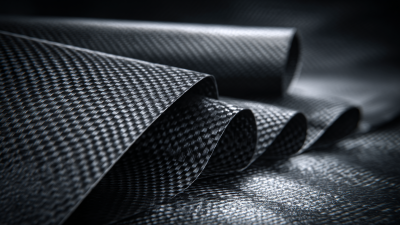

Another important specification to consider is the fiber orientation. Carbon fiber sheets can exhibit different properties based on how the fibers are aligned—whether they are unidirectional or woven. Woven sheets typically offer balanced strength in multiple directions, which can be beneficial for applications with varying stress patterns.

Tip: Review the mechanical properties of different orientations to find the best match for your project’s demands. Understanding these can significantly affect the performance and durability of your end product.

When selecting large carbon fiber sheets for your project, several critical factors should be taken into account. Firstly, the mechanical properties of the carbon fiber, including tensile strength and modulus, are paramount. Reports indicate that carbon fiber's tensile strength can exceed 600 MPa, making it significantly stronger than traditional metals. This quality makes it an excellent choice for applications requiring high strength-to-weight ratios, especially in the automotive industry where lightweight materials are emphasized for improved fuel efficiency and performance. Recent studies highlight that advancements in lightweight composite structures have led to the creation of materials that not only reduce vehicle weight but also enhance safety through improved energy absorption during impact.

Another essential consideration is the manufacturing process and design versatility of the carbon fiber sheets. With innovative techniques emerging, such as the use of adhesively bonded joints, the design possibilities have expanded dramatically. By utilizing these advanced joining methods, manufacturers can create complex, lightweight structures that were previously unattainable using conventional materials. Additionally, the ability to customize sheet sizes and thicknesses according to specific project demands allows for greater flexibility and efficiency in production, further underscoring the advantages of large carbon fiber sheets in modern engineering applications.

When selecting large carbon fiber sheets for your project, understanding the different types available is crucial. One primary factor to consider is the weave pattern. Traditional fabrics, such as plain or twill weaves, offer a balance of strength and flexibility. According to a report from the Composite Materials Handbook, plain weave provides a tensile strength of approximately 500 MPa, making it suitable for applications that require durability and minimal stretching. In contrast, twill weaves, known for their smoother appearance and enhanced drapability, can endure higher loads, making them ideal for intricate designs while maintaining performance under stress.

Another essential consideration is the thickness of the carbon fiber sheets. Thicker materials (typically ranging from 0.5 mm to 6 mm) provide greater rigidity and impact resistance, vital for aerospace and automotive applications. As detailed by the American Composites Manufacturers Association, sheets above 2 mm can significantly enhance structural integrity, offering a strength-to-weight ratio that is up to five times that of metals like aluminum. On the other hand, thinner sheets (0.5 mm to 1 mm) keep projects lightweight, making them a preferred choice for industries such as cycling and high-performance sports equipment where reducing weight is a priority. By evaluating these variables, project managers can choose the optimal carbon fiber sheet that meets their specific technical requirements.

When selecting large carbon fiber sheets for your project, assessing the supplier's reputation and adhering to material quality standards are crucial steps that can significantly influence the outcome. Research indicates that over 60% of project failures are attributed to subpar materials and inconsistent quality (Source: Composite Manufacturing Association). Therefore, it’s crucial to partner with suppliers who have a proven track record of reliability and product excellence.

It's advisable to evaluate suppliers based on their certifications and industry recognition. According to a 2021 report by MarketsandMarkets, suppliers adhering to ISO 9001 quality management standards not only ensure consistent quality but also demonstrate a commitment to continuous improvement. Additionally, reviewing client testimonials and case studies can provide insights into how the supplier's materials perform in real-world applications. A supplier's history in the industry, supported by verified data showing their products' durability and performance metrics, is invaluable in making an informed decision about your carbon fiber sheet procurement.

Large carbon fiber sheets are increasingly popular in various industries due to their lightweight yet high-strength properties. In the aerospace sector, for example, these sheets are utilized to manufacture components such as aircraft wings and fuselage parts. The reduced weight contributes to fuel efficiency and overall performance, making carbon fiber an ideal choice for this demanding field. Additionally, the automotive industry benefits from carbon fiber sheets in the production of high-performance vehicles, where every gram counts for speed and efficiency. Parts like hoods, spoilers, and interior components made from carbon fiber not only enhance aesthetics but also improve structural integrity.

Beyond aerospace and automotive, large carbon fiber sheets find applications in the marine industry as well. Boat manufacturers often use these materials for constructing hulls and masts, as they provide an excellent strength-to-weight ratio that enhances speed and maneuverability. Furthermore, the sports industry leverages carbon fiber in equipment like bicycles, tennis rackets, and fishing rods, where enhanced performance and reduced weight significantly impact user experience.

As different sectors continue to explore the potential of large carbon fiber sheets, their versatility and innovative applications are set to revolutionize the way products are designed and manufactured, driving advancements across multiple fields.