-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

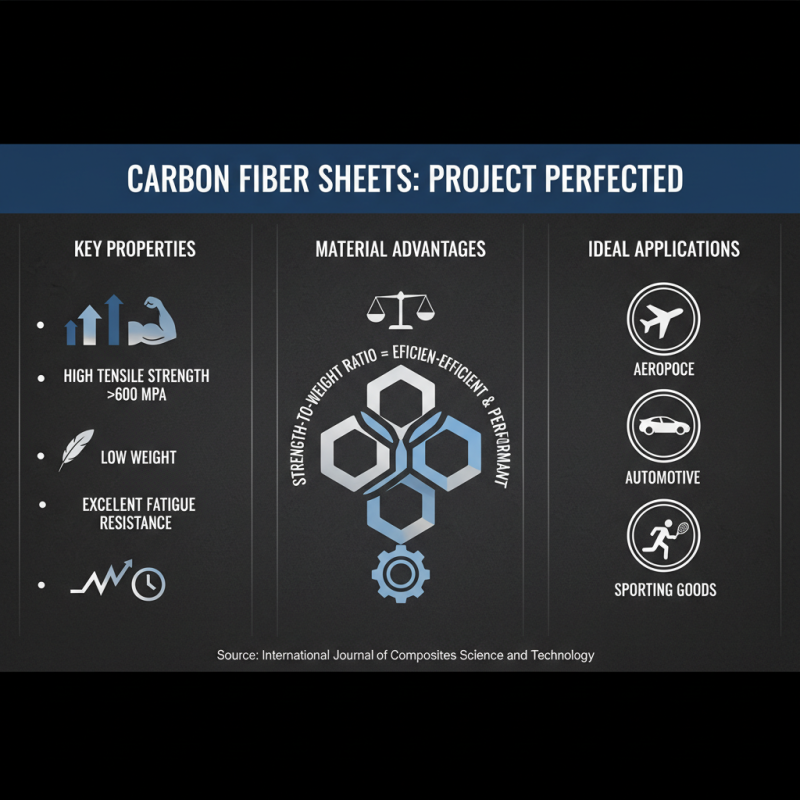

In recent years, the demand for lightweight and high-strength materials in various industries has significantly increased, driving the popularity of carbon fiber sheets. According to a report by MarketsandMarkets, the carbon fiber market is projected to reach $5.5 billion by 2025, growing at a CAGR of 9.2%. This surge can be attributed to the unique properties of carbon fiber sheets, such as high tensile strength, low weight, and excellent fatigue resistance, making them an ideal choice for applications in aerospace, automotive, and sports equipment, among others.

Choosing the right carbon fiber sheet for your project is crucial, as the material not only impacts the performance and durability of your final product but can also influence its cost-effectiveness. Factors to consider include the type of resin used, the thickness of the sheet, and the specific manufacturing process. A comprehensive understanding of these elements can lead to optimal material selection, ensuring that the carbon fiber sheet meets the specific requirements of your project while adhering to industry standards and enhancing overall efficiency.

When choosing the right carbon fiber sheet for your project, understanding the material's properties is crucial. Carbon fiber sheets are known for their high tensile strength, low weight, and excellent fatigue resistance. According to a report by the International Journal of Composites Science and Technology, carbon fiber composites can exhibit a tensile strength of over 600 MPa, making them ideal for applications in aerospace, automotive, and sporting goods. This strength-to-weight ratio allows for the creation of lightweight yet strong components, meeting demands for efficiency and performance across various industries.

Additionally, the versatility of carbon fiber sheets extends to their thermal and electrical conductivity. Data from the Composite Manufacturing Association indicates that these sheets can handle temperatures up to 180°C while maintaining structural integrity. Furthermore, the material's electrical conductivity can be tailored by incorporating different resin systems, making it an excellent choice for applications in electronics. For projects requiring specific tolerances or environmental resistance, it is essential to consider the resin types and the curing process, as these factors significantly influence the sheet's overall properties and performance in real-world conditions.

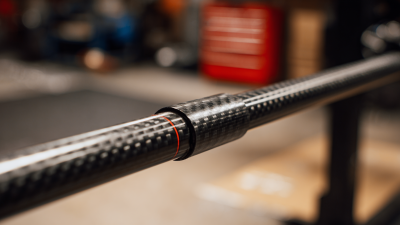

When selecting a carbon fiber sheet for your project, one of the most crucial factors to consider is the thickness of the material. The thickness not only influences the strength and rigidity of the final product but also plays a vital role in weight considerations. Thicker sheets typically provide enhanced structural support, making them suitable for applications requiring durability, such as aerospace or automotive components. However, increasing thickness can also add weight, which may be undesirable in lightweight applications like drones or high-performance sporting equipment. Therefore, it's essential to balance the need for strength with the desired weight characteristics of your project.

In addition to thickness, the weight of the carbon fiber sheet is another key factor to contemplate. Weight specifications can vary significantly based on the type of weave and resin used. For instance, a lighter sheet might be beneficial for applications where speed and agility are paramount, while a heavier sheet may be necessary for applications requiring additional strength and impact resistance. Understanding the specific demands of your project will guide you in determining the optimal weight and thickness combination, ensuring you achieve the desired performance without compromising on other critical aspects such as flexibility and durability.

When selecting the right carbon fiber sheet for your project, it’s essential to understand the various types available and their specific applications. Carbon fiber sheets primarily differ in terms of weave patterns, thickness, and resin systems. Commonly used types include twill weave, unidirectional, and prepreg carbon fiber sheets. For instance, twill weave sheets are well-known for their aesthetic appeal and flexibility, making them ideal for automotive and aerospace applications where both strength and weight reduction are crucial.

According to a recent industry report by Future Market Insights, the demand for carbon fiber composites is expected to grow at a CAGR of 10% through 2030, driven largely by the aerospace, automotive, and sporting goods sectors. In aerospace applications, where structural integrity is paramount, unidirectional carbon fiber – known for its high tensile strength in one direction – becomes a preferred option. Conversely, in automotive applications, the requirement often leans towards prepreg sheets that offer a balance of performance and ease of fabrication. This comprehensive understanding of carbon fiber types allows engineers and designers to choose materials that are optimal for meeting the unique demands of their projects.

When selecting a carbon fiber sheet for your project, evaluating the balance between cost and performance is crucial. According to a recent industry report from MarketsandMarkets, the carbon fiber market is expected to grow at a CAGR of over 10% from 2021 to 2026. This growth indicates increasing demand for high-performance materials across various sectors, including automotive, aerospace, and sporting goods. However, with advancing technology, the prices of carbon fiber materials are becoming more competitive. For projects with tight budgets, understanding the performance characteristics required can help in making a more economical decision.

Performance metrics such as tensile strength, weight-to-strength ratio, and stiffness can greatly influence the suitability of a carbon fiber sheet for specific applications. A study published by the Journal of Composite Materials indicates that high-end carbon fiber sheets can offer tensile strengths exceeding 600 MPa, which is significantly higher than that of many traditional materials. However, these advanced sheets often come with a premium price tag. For less demanding applications, opting for a lower grade carbon fiber that still provides adequate performance could yield significant cost savings while meeting the necessary project specifications. Balancing these performance attributes with cost considerations will enable project managers and engineers to make informed decisions tailored to their specific needs.

When sourcing high-quality carbon fiber sheets for various projects, it is essential to pay attention to standards and certifications that ensure the material's performance and reliability. One of the primary considerations is to look for sheets that comply with recognized industry standards such as ASTM or ISO certifications. These standards provide assurance that the carbon fiber meets specific criteria related to strength, stiffness, and manufacturing processes. Understanding these benchmarks can help project managers and engineers make informed decisions based on performance expectations.

Additionally, certification from reputable organizations can play a crucial role in verifying the quality of carbon fiber sheets. Certifications may include information on the resin system used, the fiber tensile strength, and the overall composite properties. When selecting materials, it is advisable to request documentation that outlines these certifications, as they serve as a guarantee that the materials will perform under specified conditions.

Whether you are working on aerospace applications, automotive components, or sporting equipment, ensuring that your carbon fiber sheets are sourced from certified suppliers can significantly impact the success and durability of your final product.