-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

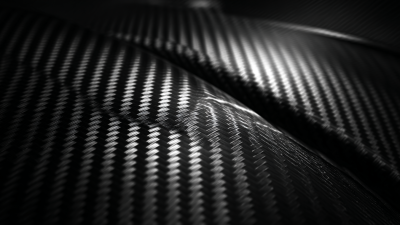

When it comes to selecting the optimal Carbon Fiber Webbing for your specific applications, understanding the unique properties and advantages of this material is crucial. According to a recent market analysis by Grand View Research, the demand for carbon fiber materials is projected to reach USD 6.51 billion by 2025, driven by their lightweight yet high-strength characteristics. Carbon Fiber Webbing, in particular, is increasingly favored in industries such as aerospace, automotive, and sports equipment for its superior performance and durability. With its ability to withstand extreme conditions and provide increased tensile strength, selecting the right type of Carbon Fiber Webbing can significantly enhance the functionality and longevity of your projects. This guide will help you navigate the selection process, ensuring that your specific needs are met with the appropriate carbon fiber solutions.

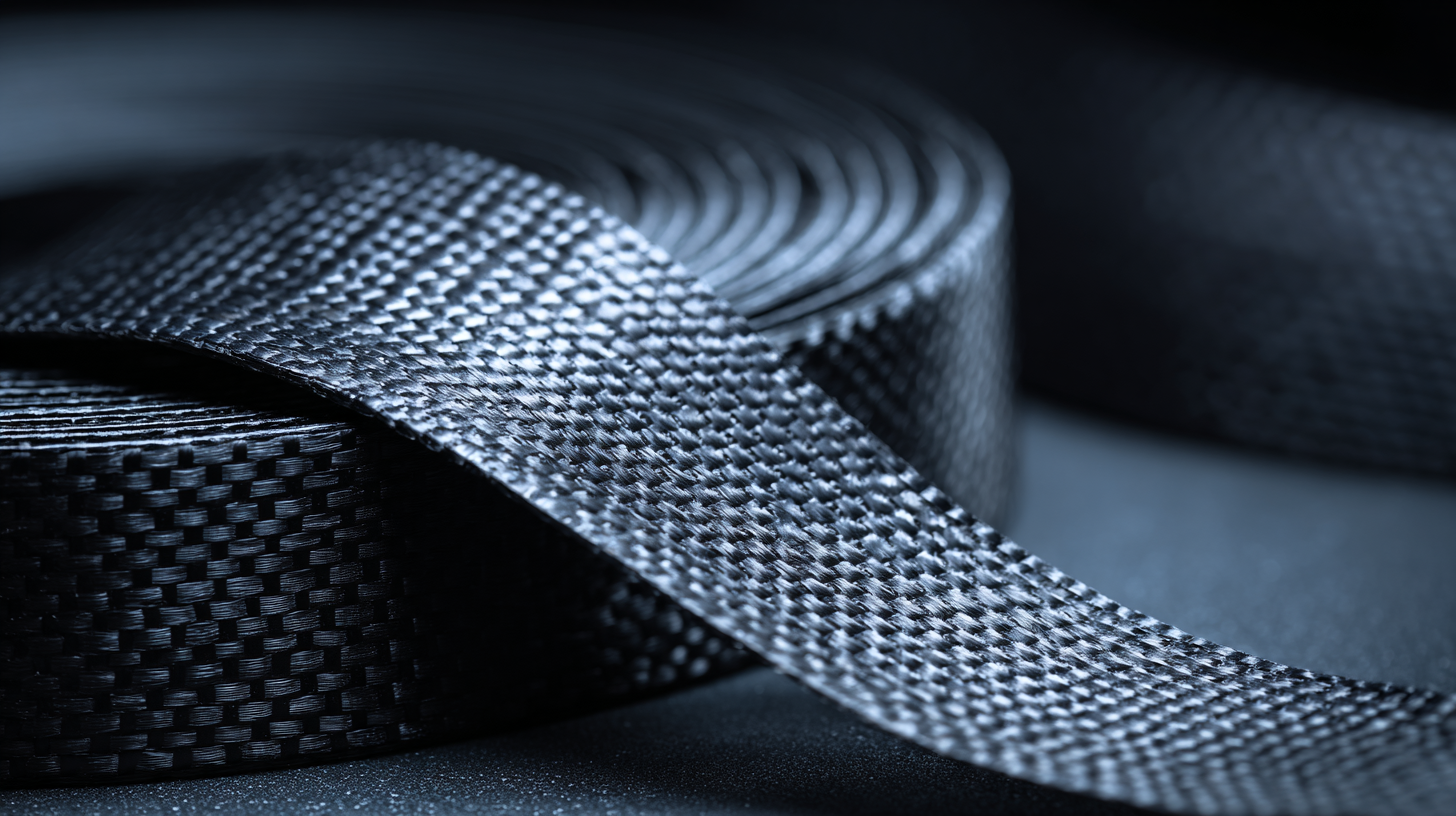

When selecting the right carbon fiber webbing for your specific needs, it's essential to understand the various types available in the market. Carbon fiber webbing is primarily categorized into different grades—standard, intermediate modulus, and high modulus—each offering unique benefits tailored to specific applications. According to recent industry reports, the demand for high modulus carbon fiber, which boasts an impressive tensile modulus range of up to 250 GPa, has surged in high-performance sectors such as aerospace and automotive, where rigidity and weight reduction are critical.

Moreover, the market features various weaves, such as plain, twill, and satin, which influence the webbing's strength, flexibility, and aesthetic appeal. For instance, plain weaves provide excellent stability and are commonly used in applications requiring enhanced strength, while satin weaves offer a smoother surface and more flexibility, making them suitable for applications like sporting goods. A report from the Composites Market Group indicated that the global market for carbon fiber products is expected to grow at a CAGR of 10% through 2027, driven by the increasing demand in sectors that prioritize lightweighting and performance. Understanding these nuances is crucial for selecting the optimal carbon fiber webbing to meet your project criteria effectively.

When selecting the right carbon fiber webbing for your project, several key factors must be considered to ensure you meet your specific needs. First and foremost, the intended application of the webbing is crucial, as different projects may require varying levels of strength, flexibility, and weight. Understanding the load-bearing requirements and environmental conditions will guide you toward the right type of carbon fiber composition and weave structure.

Another important factor is the production technology used in manufacturing the webbing. Recent advancements in sustainable building materials have led to innovative production techniques that enhance performance while reducing environmental impact. As carbon fiber technology continues to evolve, it is essential to stay informed about the latest developments that could benefit your project. Furthermore, consider the cost implications of sourcing high-quality materials versus budget alternatives, ensuring that you achieve the best balance between performance and expense for your specific application.

| Key Factor | Description | Recommended Use |

|---|---|---|

| Weight Capacity | The maximum load the webbing can support. | Heavy-duty applications, climbing gear. |

| Width | The width of the webbing material. | Straps, belts, and harnesses. |

| Elasticity | The degree to which the webbing can stretch under load. | Applications with dynamic loads. |

| Temperature Resistance | The range of temperatures the webbing can withstand. | Use in extreme environments. |

| UV Resistance | The ability of the webbing to resist degradation from UV exposure. | Outdoor applications, marine environments. |

| Chemical Resistance | Resistance to acids, alkalis, and other chemicals. | Industrial applications. |

When selecting carbon fiber webbing, understanding its strength and durability is paramount. Carbon fiber webbing is renowned for its exceptional tensile strength and resistance to various environmental factors, making it an ideal choice for applications in aerospace, automotive, medical, and consumer industries. These sectors increasingly rely on fiber-reinforced composites due to their ability to withstand harsh conditions and deliver long-lasting performance. Evaluating the tensile strength of different carbon fiber webbing options helps in determining their efficacy for specific tasks, ensuring that the selected material can handle the required loads without compromising safety or performance.

In recent explorations, the variability in tensile strength among fiber-reinforced composites has been extensively studied, revealing valuable insights into their applications. Choosing the right carbon fiber webbing involves considering not just the general specifications, but also how these materials perform under statistical distributions of stress. This analytical approach enables manufacturers and engineers to predict the longevity and reliability of carbon fiber products, particularly in demanding settings like medical devices and structural components. By leveraging advanced manufacturing methods, such as 3D printing, the potential applications of carbon fiber webbing continue to expand, offering innovative solutions tailored to unique needs.

When considering the cost-effectiveness of carbon fiber webbing, it's essential to analyze its long-term benefits versus initial investment. Carbon fiber is renowned for its strength-to-weight ratio, making it an ideal choice for applications ranging from automotive to outdoor gear. Although the upfront cost may be higher than traditional materials, the durability and reduced maintenance requirements can lead to significant savings over time.

Tips for assessing the cost-effectiveness of carbon fiber webbing include:

When sourcing high-quality carbon fiber webbing, the first step is to identify reputable suppliers and brands with a proven track record in the industry. Look for manufacturers that specialize in advanced composite materials and have certifications that attest to their quality standards. Check their history and client testimonials to gauge their reliability and customer satisfaction. Engaging with industry forums or communities can provide insights into which suppliers are recognized for their superior products.

Another important consideration is evaluating the specific properties of the carbon fiber webbing offered by potential suppliers. Quality webbing should have excellent tensile strength, durability, and resistance to environmental factors such as UV exposure and chemical corrosion. Request product samples when possible to assess the material's performance directly. Additionally, inquire about the company's production methods and sourcing of raw materials to ensure that they adhere to sustainable practices, which can also reflect on the overall quality of their products.