-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In today’s fast-paced work environments, safety is a paramount concern, and the implementation of advanced protective equipment is essential. One such innovation that has gained significant attention is Cut Resistant Cloth. This material offers remarkable durability and protection, making it an indispensable choice across various industries, from manufacturing to healthcare. As workers encounter an array of sharp tools and materials, the adoption of Cut Resistant Cloth not only enhances personal safety but also boosts confidence and efficiency on the job. In this blog, we will explore the top five reasons why integrating Cut Resistant Cloth into modern workplaces is beneficial, ensuring a safer and more productive environment for all employees. Whether you’re a business owner or an employee, understanding the advantages of this cutting-edge material could transform your approach to workplace safety.

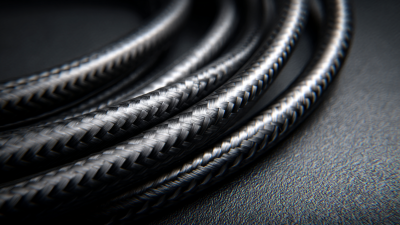

Cut resistant cloth has revolutionized safety standards in modern work environments, thanks to its innovative materials that combine durability and flexibility. The science behind these fabrics involves the use of advanced synthetic fibers, such as Kevlar or Dyneema, which are woven tightly to create a protective barrier against sharp objects. These fibers are not only resilient but also lightweight, ensuring that workers can perform their tasks comfortably without compromising safety.

Cut resistant cloth has revolutionized safety standards in modern work environments, thanks to its innovative materials that combine durability and flexibility. The science behind these fabrics involves the use of advanced synthetic fibers, such as Kevlar or Dyneema, which are woven tightly to create a protective barrier against sharp objects. These fibers are not only resilient but also lightweight, ensuring that workers can perform their tasks comfortably without compromising safety.

When selecting cut resistant clothing, it’s essential to consider the specific hazards present in your work environment. For instance, workers in manufacturing or food processing should prioritize garments that meet the appropriate cut resistance level based on their tasks. Additionally, ensure that the fit is correct for maximum mobility. Regularly inspect and replace protective gear when signs of wear and tear appear, as even the best materials have a lifespan.

Furthermore, understanding the proper maintenance of cut resistant cloth can enhance its longevity and effectiveness. Wash these garments according to the manufacturer's guidelines to avoid damaging the fibers. Avoid using bleach or harsh detergents that can weaken the material. Lastly, educate employees about the importance of wearing proper protective clothing consistently. This not only promotes a safety-first culture but also significantly reduces the risk of injuries in the workplace.

Cut resistant fabrics have emerged as a pivotal solution in modern work environments, particularly in industries prone to cuts and lacerations. Statistics reveal a significant reduction in workplace injuries when such fabrics are utilized. According to recent studies, workplaces that incorporate cut resistant clothing report a remarkable decrease in injury rates, with some data showing reductions of up to 70%. This is particularly evident in sectors like manufacturing, construction, and food processing, where sharp tools and equipment are commonplace.

Cut resistant fabrics have emerged as a pivotal solution in modern work environments, particularly in industries prone to cuts and lacerations. Statistics reveal a significant reduction in workplace injuries when such fabrics are utilized. According to recent studies, workplaces that incorporate cut resistant clothing report a remarkable decrease in injury rates, with some data showing reductions of up to 70%. This is particularly evident in sectors like manufacturing, construction, and food processing, where sharp tools and equipment are commonplace.

Moreover, the adoption of cut resistant materials not only enhances employee safety but also contributes to overall productivity. When workers feel secure in their clothing, they are more likely to focus on their tasks without the constant worry of injury. Additionally, the financial implications of reduced accidents can be substantial for companies, as fewer injuries lead to lower insurance costs and less downtime. Embracing cut resistant fabrics is not just a matter of compliance; it is a proactive step towards fostering a safer and more efficient workplace.

When selecting cut resistant cloth for modern work environments, understanding the key features and industry standards is crucial. Look for materials that comply with the latest safety regulations, such as those set by ANSI/ISEA. This ensures that the cloth you choose provides adequate protection against sharp objects while maintaining comfort and flexibility.

One important tip is to consider the cut resistance level that corresponds to your specific work requirements. The levels range from A1 to A9, with higher levels indicating stronger protection. For instance, food processing and glass handling industries typically require higher cut levels due to the nature of the materials involved.

Additionally, pay attention to other qualities such as breathability, grip, and durability. Fabrics with moisture-wicking properties can enhance comfort during long shifts, while reinforced areas can provide extra protection where it's needed most. Opting for cut resistant cloth that balances safety and functionality will help ensure a safer work environment.

Implementing cut-resistant gear is essential in today’s workplaces where the risk of injuries from sharp tools and materials is prevalent. To maximize the benefits of this protective equipment, training employees is crucial. A comprehensive training program should not only focus on the correct usage of cut-resistant clothing but also instill a culture of safety awareness. Employees must understand the significance of wearing appropriate gear, recognizing hazards, and following safety protocols that prevent accidents.

Practical training sessions can be immensely beneficial, where employees learn to identify potential risks in their specific work environments. Demonstrations on how to wear and maintain cut-resistant gear can enhance their comfort and confidence. Additionally, regular refreshers and updates on safety practices can keep cut-resistant measures at the forefront of everyone’s mind, fostering a proactive approach to workplace safety. As employees become more knowledgeable about their equipment and the importance of safety, they become vital players in reducing workplace injuries, creating a safer and more productive work environment for all.

As we move deeper into the Fourth Industrial Revolution (4IR), the integration of advanced technologies such as artificial intelligence (AI) and robotics is reshaping various aspects of the workplace, including employee safety and material innovation. One notable advancement is in cut-resistant technology, which has become increasingly vital in modern manufacturing environments. According to recent reports, the global cut-resistant gloves market is projected to grow by over 10% annually by 2025, reflecting the rising demand for enhanced protective gear amid a shift towards automated processes.

The future trends in cut-resistant cloth technology are also promising, with innovations focusing on lightweight materials that offer superior protection without sacrificing comfort. A significant aspect of this evolution is the embedding of smart materials that can measure exposure to hazardous conditions, providing real-time feedback to workers. This integration of IoT capabilities not only increases safety among workers but also aligns with sustainability goals in Industry 4.0, where reducing waste and optimizing material usage are paramount. As companies invest in these advanced textile technologies, they simultaneously bridge the gap between safety and efficiency, ensuring that the workforce is both protected and empowered in an increasingly automated world.