-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

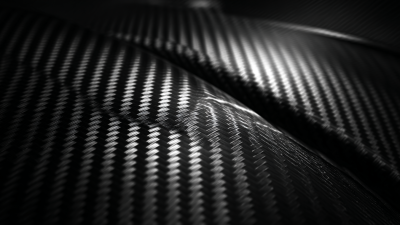

In the realm of advanced materials, carbon fiber has emerged as a powerhouse due to its remarkable strength-to-weight ratio and versatility. However, the process of working with carbon fiber sheet cutting can be complex and requires a refined approach to achieve optimal results. Whether you are a seasoned professional or a novice in composite materials, mastering the techniques of carbon fiber sheet cutting is essential for producing high-quality components that meet demanding specifications.

This article delves into the top ten tips that will enhance your carbon fiber sheet cutting practices. By understanding the unique properties of carbon fiber and employing effective cutting techniques, you can improve precision, reduce waste, and ensure the integrity of your materials. From selecting the right tools and equipment to adopting proper safety measures, each tip is designed to help you navigate the intricacies of working with carbon fiber efficiently. Get ready to elevate your skills and achieve excellence in carbon fiber sheet cutting.

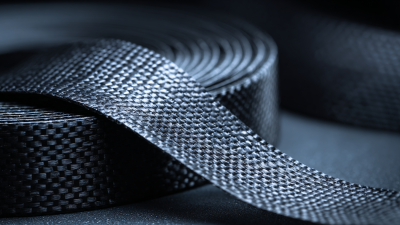

Understanding the properties of carbon fiber sheets is crucial for achieving precise and clean cuts. Carbon fiber is renowned for its high strength-to-weight ratio, making it an ideal material for various applications, from aerospace components to sports equipment.

However, its unique structure, which consists of many thin strands of carbon filaments, can pose challenges during cutting. The rigidity and brittleness of carbon fiber sheets require specific techniques and tools to avoid fraying or delamination, which can compromise the integrity of the final product.

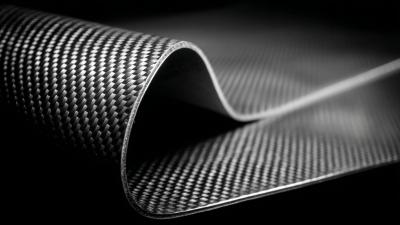

When cutting carbon fiber, it's essential to appreciate its thermal properties. Carbon fiber sheets can conduct heat, which may lead to overheating during cutting processes like laser cutting or machining. This overheating can result in resin degradation, leading to a loss in strength and quality.

To minimize heat buildup, utilizing tools that offer sharp, clean cuts, such as diamond-tipped blades or specialty saws, is recommended. Additionally, employing a low cutting speed and ensuring adequate ventilation can help manage temperatures, preserving the material's mechanical properties while achieving accurate cuts.

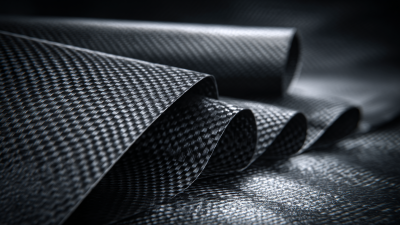

When cutting carbon fiber sheets, having the right tools and equipment is crucial to achieve precise results and maintain safety. A high-quality cutting tool, such as a diamond blade saw or a circular saw, is essential for obtaining clean cuts without fraying the edges. Additionally, a vacuum system should be utilized to control dust and debris, which not only helps in keeping the workspace clean but also protects respiratory health.

While preparing to cut, ensure you have protective gear on hand, including gloves and safety goggles, as working with carbon fiber can produce sharp splinters and harmful particles. Moreover, an adjustable workbench or a sturdy cutting table can provide stability and support during the cutting process, improving the overall accuracy of your work.

One effective tip for cutting carbon fiber is to score the material lightly before making deeper cuts. This technique helps to guide the blade along the desired line and reduces the risk of chipping. Additionally, keeping the cutting speed consistent can prevent overheating, which may weaken the fibers and affect the integrity of the material. Always make sure to measure precisely and mark your cutting lines clearly to enhance the overall efficiency of your carbon fiber sheet cutting process.

| Tip Number | Cutting Technique | Essential Tools | Safety Equipment | Additional Considerations |

|---|---|---|---|---|

| 1 | Using a CNC Machine | CNC Router | Face shield, gloves | Ensure proper calibration of the machine. |

| 2 | Manual Cutting | Utility Knife, Scissors | N95 Mask, goggles | Use steady pressure to achieve clean cuts. |

| 3 | Water Jet Cutting | Water Jet Cutter | Safety gloves, ear protection | Ideal for intricate shapes. |

| 4 | Laser Cutting | Laser Cutter | Laser safety glasses | Requires a ventilation system. |

| 5 | Band Saw Cutting | Band Saw | Safety goggles, gloves | Adjust blade speed for optimal results. |

| 6 | Dremel Tool Cutting | Dremel Tool | Respirator mask | Use appropriate bit for the material. |

| 7 | Score and Snap Method | Scoring Tool | Safety goggles | Best for straight cuts with minimal waste. |

| 8 | Shearing | Shearing Machine | Protective gloves | Efficient for sheet materials. |

| 9 | Hot Wire Cutting | Hot Wire Cutter | Face shield, heat-resistant gloves | Good for thicker materials. |

| 10 | Tile Saw | Wet Tile Saw | Safety glasses, mask | Pre-soak the fiber for smoother cuts. |

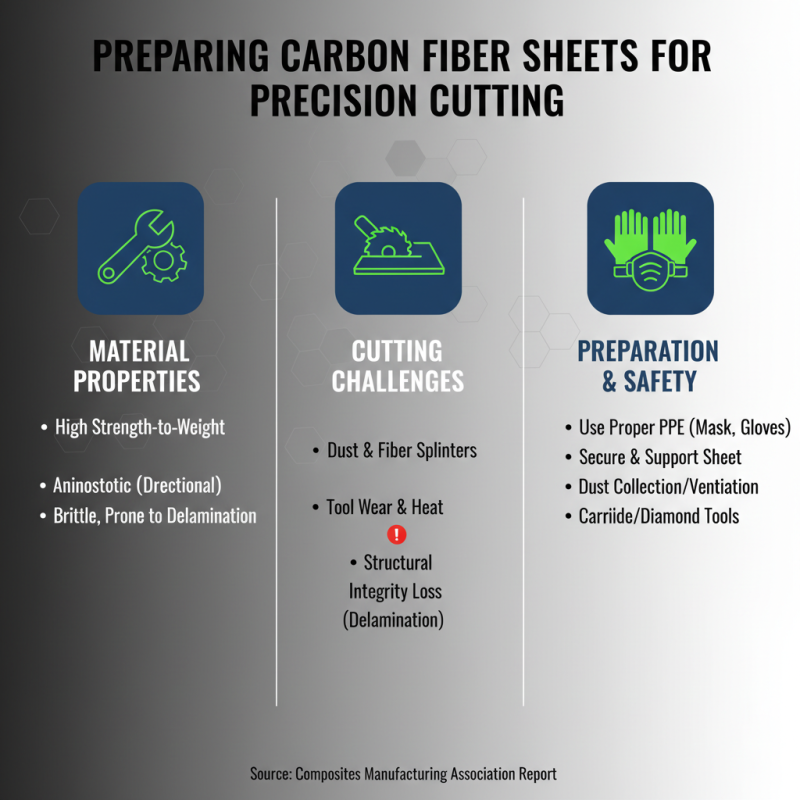

Preparing carbon fiber sheets for cutting requires an understanding of the material's unique properties and specific techniques to ensure precision and quality. Carbon fiber, known for its high strength-to-weight ratio, presents challenges during the cutting process. According to a report by the Composites Manufacturing Association, incorrect cutting methods can result in structural integrity loss, underscoring the importance of proper preparation.

Begin by selecting the right tools and workspace. A dedicated space equipped with a sharp, high-quality diamond blade saw is ideal for clean cuts, as standard blades may not provide the necessary precision. The American Society for Testing and Materials (ASTM) suggests pre-measuring and marking your cutting lines with precision tools to minimize errors. Using clamps to secure the sheets can help prevent movement during cutting, which is crucial for achieving clean edges and avoiding splintering.

Additionally, consider the cutting speed and technique. Slower speeds typically yield better results and reduce the risk of heat buildup, which can damage the resin in the composite material. A study published in the Journal of Composite Materials found that optimal cutting speeds vary depending on the thickness of the sheets; for thicker materials, a lower RPM is often recommended. By following these guidelines, fabricators can ensure that their carbon fiber sheets are prepared accurately for cutting, ultimately enhancing the overall quality of the final product.

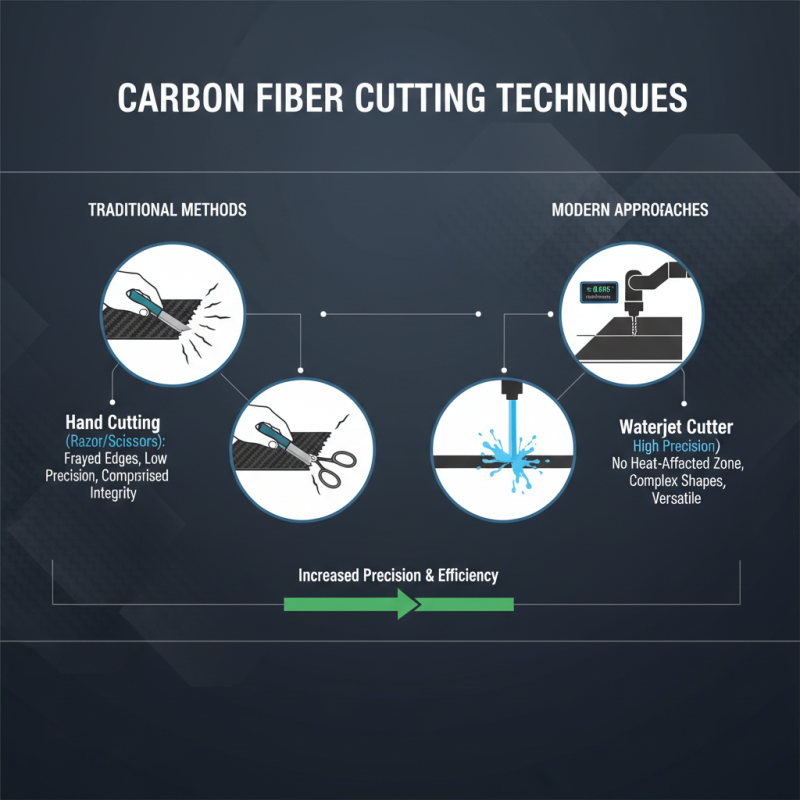

When it comes to cutting carbon fiber sheets, selecting the right technique can significantly impact both precision and efficiency. Traditional methods, such as hand cutting with razor blades or scissors, can often lead to frayed edges, which may compromise the structural integrity of the material. On the other hand, modern approaches leveraging CNC routers and waterjet cutters have gained popularity in the industry. Reports indicate that CNC machines can achieve tolerances of ±0.005 inches, making them a preferred choice for high-precision applications.

Tips for effective cutting include ensuring proper tool selection and maintenance. Using diamond-coated blades can help in minimizing dust and providing clean cuts. Additionally, optimizing the cutting speed and feed rates can reduce the risk of delamination, which is crucial since studies show that improperly cut carbon fiber can weaken the finished product by up to 30%.

Another consideration is the use of protective layering, which can safeguard against fibers fraying during the cutting process. The introduction of modern vacuum systems during cutting can also enhance precision and ensure cleaner working conditions, making the setup not only more efficient but safer as well. As the demand for advanced materials increases across various sectors, adopting innovative cutting techniques is essential for maintaining competitive advantages in the industry.

Cutting carbon fiber sheets requires not only precision but also a strong emphasis on safety. Given that carbon fiber is made up of extremely fine filaments that can become airborne during cutting, it’s essential to wear proper personal protective equipment (PPE). This includes dust masks or respirators to prevent inhalation of harmful particles, safety goggles to protect the eyes from flying debris, and gloves to safeguard against any sharp edges. According to industry safety data, over 25% of respiratory issues in composite fabrication are linked to improper handling and cutting techniques, highlighting the necessity for appropriate precautions.

In addition to personal safety, establishing a controlled cutting environment is vital. Utilizing wet cutting methods can minimize dust production, which is beneficial for both operator health and equipment longevity. The United States Occupational Safety and Health Administration (OSHA) notes that particulate matter can lead to long-term health problems, emphasizing the importance of controlling airborne contaminants. Furthermore, maintaining a clean workspace free of debris will not only enhance precision during cutting but also reduce the risk of accidents. Implementing these best practices ensures a safer working environment while achieving the best results in carbon fiber sheet cutting.