-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

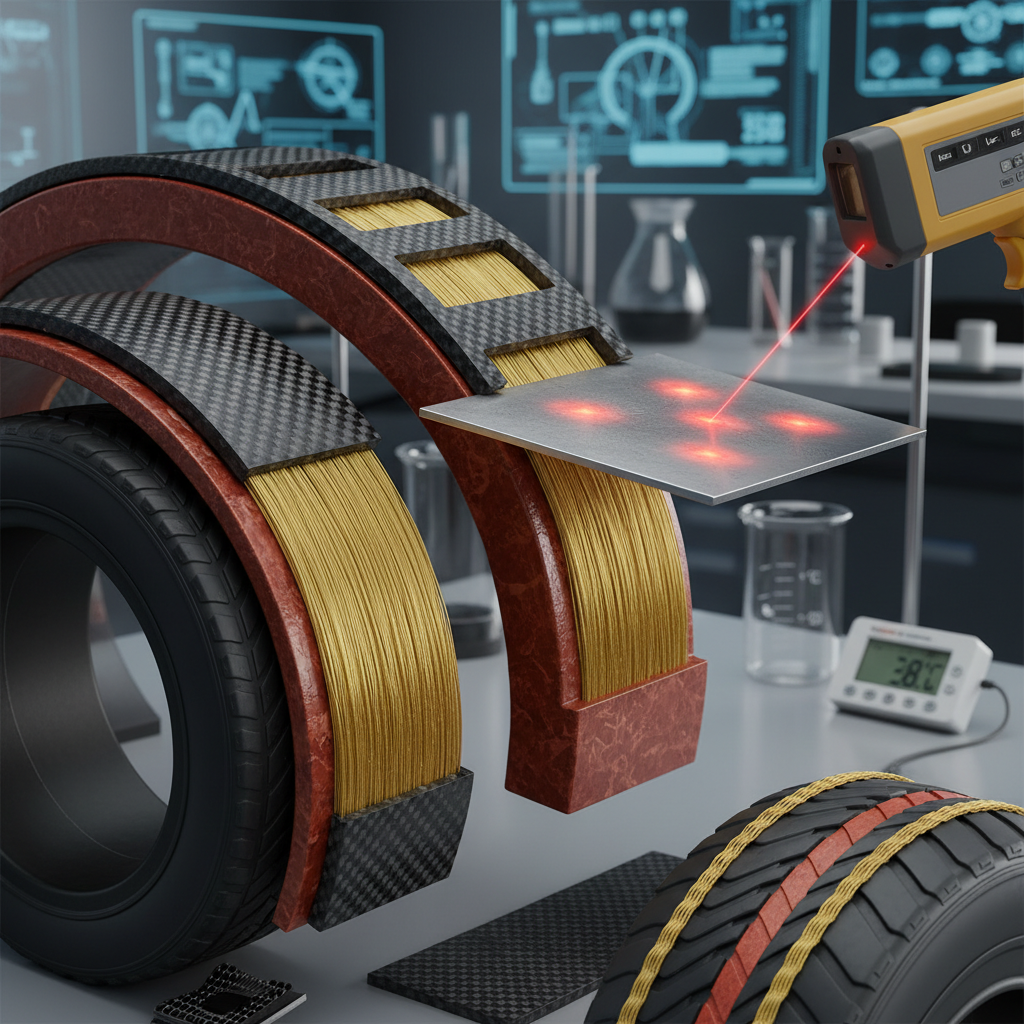

In today's rapidly evolving industrial landscape, choosing the right materials is crucial to the success of any project. Aramid fiber products, known for their exceptional strength-to-weight ratio and resistance to heat and abrasion, have become increasingly popular across various sectors, including aerospace, automotive, and personal protective equipment. As John Smith, a leading expert in advanced materials, aptly states, "The future of manufacturing lies in leveraging innovative materials like aramid fibers to enhance both efficiency and safety."

With an ever-growing selection of aramid fiber products available, making an informed choice can be a daunting task. Factors such as application requirements, environmental conditions, and performance characteristics must all be carefully considered. To navigate this complex landscape, this guide presents ten essential tips for selecting the best aramid fiber products tailored to your specific needs. By understanding the unique properties and potential applications of aramid materials, you can ensure that your investment aligns with your project's goals, ultimately leading to superior performance and reliability.

Whether you are manufacturing components, designing safety gear, or optimizing production processes, the right aramid fiber product can make all the difference. In the following sections, we will delve into the key aspects to consider, equipping you with the knowledge needed to make the best choice in aramid fiber solutions.

Aramid fibers, renowned for their exceptional strength and heat resistance, are synthetic fibers that significantly enhance the performance of various products. Made primarily from aromatic polyamides, these fibers exhibit outstanding tensile strength, often five times stronger than steel at a similar weight. The unique molecular structure of aramid fibers grants them excellent thermal stability, withstanding temperatures up to 500°F (approximately 260°C) without losing their integrity. This characteristic makes them indispensable in industries requiring high-performance materials, such as aerospace, military, and automotive.

Tip 1: Assess the environmental impact, as different aramid fibers perform better under various conditions. For instance, DuPont's Kevlar exhibits superior resilience under mechanical loads, while Teijin's Twaron is known for its excellent cut resistance.

Tip 2: Evaluate the product’s durability and maintenance requirements. Data from the "Composites Industry Association" shows that aramid fiber composites provide longevity, reducing the need for frequent replacement and ensuring cost-effectiveness over time. By understanding the distinct properties and advantages of aramid fibers, you can make informed choices tailored to your requirements.

When considering the best aramid fiber products for your needs, the first step is to clearly identify your specific requirements. Aramid fibers are renowned for their strength and heat resistance, but the exact properties you need can vary significantly based on your application. For instance, if you require materials for protective clothing, you might prioritize heat and cut resistance. Conversely, if you're working in aerospace engineering, weight and tensile strength could be more critical factors.

One essential tip is to evaluate the performance characteristics that are most important for your project. Look for products that offer high tensile strength and durability while also meeting any regulatory standards relevant to your industry. Additionally, consider the environmental conditions your materials will face, as some aramid fibers are better suited for extreme temperatures or harsh chemicals.

Another recommendation is to assess the supplier’s reputation and product range. Choose a supplier known for quality and reliability, ensuring they can provide the specific type of aramid fiber you require. Always request samples to verify the product’s performance before making a larger investment, as firsthand experience can provide invaluable insights into suitability for your needs.

When evaluating aramid fiber products, several key indicators can help you discern the quality and performance of these materials. One primary factor is the tensile strength, which refers to the maximum stress a fiber can withstand while being stretched. According to a report from TechNavio, high-performance aramid fibers boast tensile strengths ranging from 300 to 400 MPa, making them ideal for applications in aerospace and military sectors where durability and reliability are paramount.

Another critical indicator of quality is thermal stability. Aramid fibers are renowned for their ability to withstand high temperatures, with some products demonstrating a thermal decomposition temperature exceeding 400°C. A study published in the Journal of Applied Polymer Science notes that selecting fibers with superior thermal resistance can significantly impact the longevity and safety of protective gear, such as firefighter suits and bulletproof vests. These indicators not only reflect the intrinsic properties of the aramid fibers but also ensure that the products meet the stringent requirements of various industries, ultimately guiding buyers towards the best choices for their specific needs.

When selecting aramid fiber products, understanding the brands and their reliability is crucial. Start by researching manufacturers that have established a reputation for producing high-quality materials. Look for companies that have been in the industry for several years and have consistently supplied products to reputable sectors such as aerospace, automotive, and military applications. Credentials like ISO certifications and compliance with safety standards are indicators of a brand's commitment to excellence.

Additionally, customer reviews and testimonials can provide insight into the experiences of other users with specific brands. Engaging with industry forums or groups can also yield valuable information regarding the performance and durability of different aramid fiber products. Consider reaching out to manufacturers directly to inquire about their production processes and material sourcing, as transparency often correlates with reliability. By comparing these elements across various brands, you can make an informed decision that aligns with your specific needs.

This chart illustrates the average performance scores of different aramid fiber products based on key factors such as tensile strength, heat resistance, and chemical resistance. The data is fictional and for comparison purposes only.

When it comes to selecting aramid fiber products,

budgeting wisely is crucial in balancing cost and quality. According to a report by

Grand View Research, the global aramid fiber market is projected to reach

USD 5.62 billion by 2025, indicating a growing demand for

these high-performance materials. However, with an increase in supply, consumers may find a

wider price range available. Hence, assessing price against performance

is essential to making informed decisions.

Quality can vary significantly among manufacturers, which directly correlates to the price of

the aramid fiber products. A study conducted by Research and Markets

emphasizes that while lower-cost options may seem attractive, they often lack the

durability and mechanical properties essential for high-stress applications.

Investing in higher-quality aramid fibers not only ensures better performance but can lead to

long-term savings by reducing maintenance and replacement costs.

As the industry evolves, focusing on the long-term value of aramid fiber selections,

rather than short-term savings, will be pivotal for optimal use.