-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Choosing the right Carbon Fiber Rope can feel overwhelming. With countless options available, making the right choice is crucial for performance and safety. Renowned expert in material science, Dr. Emily Carter, once said, "The right rope is not just about strength; it's about reliability in real-world applications." This highlights the importance of understanding your specific needs when selecting Carbon Fiber Rope.

Carbon Fiber Rope is known for its lightweight and incredible tensile strength. However, not all ropes are the same. Different applications may require different specifications. It’s essential to consider the working load limit, environmental exposure, and flexibility. These factors play a significant role in your rope's performance. Sometimes, choices may seem clear but can lead to unexpected challenges.

Reflecting on past experiences, many users have faced issues due to improper rope selection. Choosing a rope should not be a rushed decision. Take time to research and consult experts in the field. Remember, an informed decision can make all the difference in the effectiveness of your Carbon Fiber Rope.

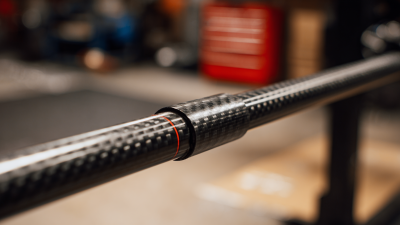

When selecting carbon fiber rope, it's vital to understand its unique properties. This material is lightweight yet exceptionally strong. Carbon fiber ropes can withstand extreme tension, making them ideal for various applications. Their resistance to abrasion further enhances durability. This means they won’t break down easily under harsh conditions.

One drawback to consider is the price. Carbon fiber rope can be more expensive than alternatives. This may necessitate a careful budget assessment. Additionally, while they are resistant to many chemicals, they are not impervious to all. For instance, some solvents can degrade their integrity. This is crucial to remember when using them in specific environments. Understanding these factors will help you make a more informed choice.

When choosing the right carbon fiber rope, strength and load capacity are critical factors. Carbon fiber ropes are known for their lightweight yet robust nature. Evaluating their strength involves understanding the material construction. High-quality carbon fiber can handle intense stress while remaining flexible.

Consider the rope’s load capacity. This capacity must exceed the maximum load you plan to use. Pay attention to the specifications provided by the manufacturer. Not all ropes will perform under extreme conditions. Knowing your requirements is essential.

Tip: Look for detailed specifications. Some products may exaggerate their strength. Another tip is to consider environmental factors. UV exposure and moisture can degrade the rope's integrity. Test the rope under real-world conditions if possible. You want to ensure it won’t fail when you need it most. Ultimately, a thorough evaluation will help you choose wisely.

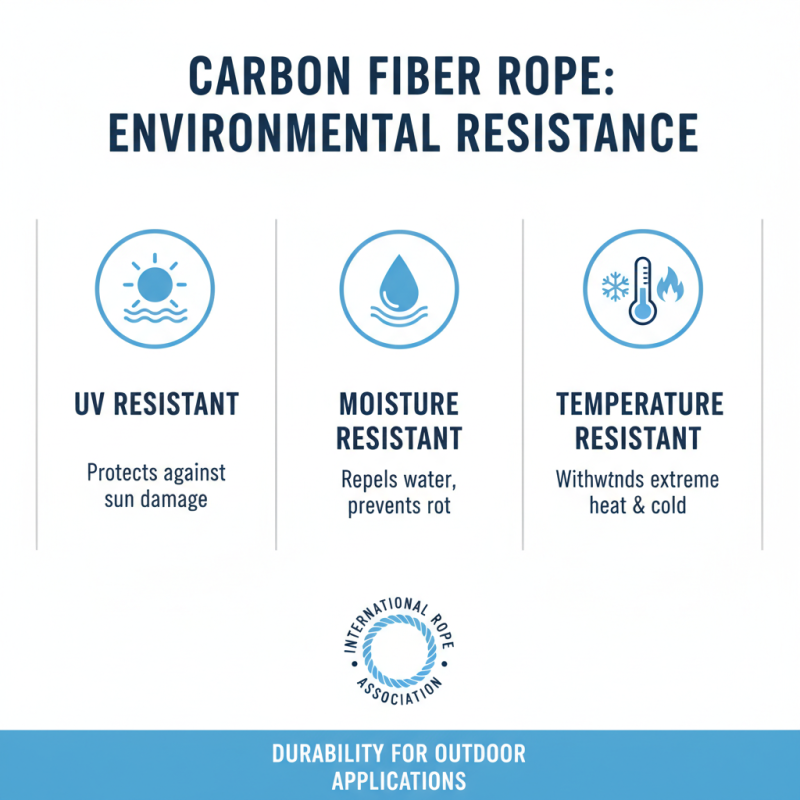

When choosing carbon fiber rope, environmental resistance is crucial. A report by the International Rope Association found that carbon fiber ropes can withstand extreme weather conditions. They resist UV rays, moisture, and temperature fluctuations. This durability is essential for outdoor applications.

Testing shows that carbon fiber ropes maintain their strength in various environmental conditions. In wet environments, these ropes lost only 5% of their tensile strength compared to traditional materials. However, factors such as prolonged exposure to chemicals can compromise their integrity. It's important to research the specific chemicals your rope may encounter.

Another aspect is abrasion resistance. Carbon fiber ropes can show wear under repetitive motion or friction. Reports indicate that while they are stronger than nylon or polyester, their surface can scuff if not monitored. Regular inspection helps catch these issues early, ensuring long-term performance. Replacing worn sections is often necessary. Balancing strength and care is key to maximizing the lifespan of your carbon fiber rope.

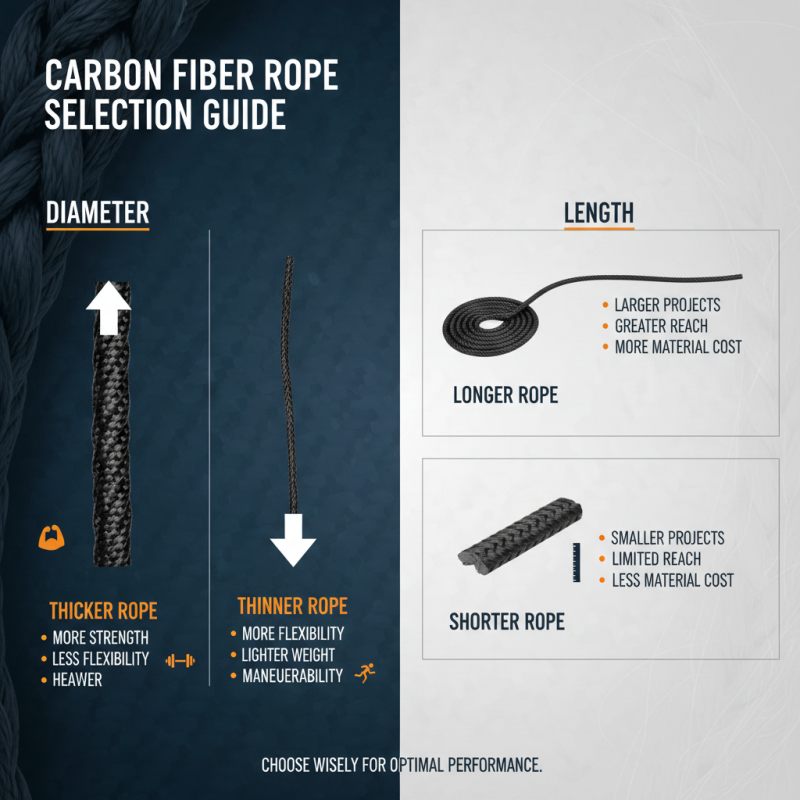

Choosing the right diameter and length for carbon fiber rope is crucial for your project. The diameter affects the rope’s strength and flexibility. A thicker diameter provides more strength. However, thicker ropes are heavier and less flexible. If your application requires maneuverability, consider a thinner rope.

Length is equally important. Measure your intended use carefully before purchasing. An excessively long rope creates unnecessary bulk. On the other hand, a rope that's too short may not fulfill its purpose. It’s wise to add a little extra length for unexpected needs. Always keep potential adjustments in mind.

Remember that factors like weather conditions can influence your choice. A stiff rope may not perform well in cold temperatures. Additionally, some users find they miscalculate and end up with ropes that don't fit their needs. Reflecting on these details can lead to better decisions. Ultimately, finding the right balance in diameter and length can enhance your project's efficiency.

When selecting carbon fiber ropes, it's critical to weigh cost against performance. Many buyers focus solely on price, overlooking key performance metrics. A cheaper option may save money upfront but might not endure harsh conditions. Durability is vital for any task. If a rope frays or fails, the cost of replacement adds up quickly.

Performance characteristics vary widely among carbon fiber ropes. Some offer exceptional tensile strength, while others prioritize flexibility. Buyers should assess their specific needs. Do you need lightweight design or heavy-duty capability? Each option carries a different price tag. Understanding these trade-offs is crucial for making an informed choice.

Testing several ropes can reveal insights that specs alone cannot. User reviews often highlight real-world performance issues. Cost considerations should not overshadow the importance of reliability. A less expensive rope that performs poorly may lead to higher expenses over time. Reflection and careful analysis can guide buyers to the best value for their requirements.