-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

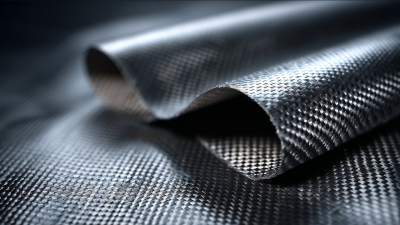

As industries continue to evolve, the demand for high-performance materials like Aramid Fabric has surged significantly, making it essential for businesses to understand effective sourcing strategies. According to a market research report by Research and Markets, the global aramid fiber market is projected to reach $7.74 billion by 2026, growing at a CAGR of 7.5% from 2021 to 2026. This growth is driven by the increasing applications of Aramid Fabric in various sectors such as aerospace, automotive, and personal protective equipment, which are known for their exceptional strength, heat resistance, and durability. To navigate the complexities of sourcing high-quality Aramid Fabric globally, it is crucial to employ best practices that ensure reliability and sustainability, ultimately contributing to a competitive edge in these fast-paced industries.

Identifying reliable aramid fabric suppliers globally can be a daunting challenge for procurement professionals. The complexity of the supply chain and the varying quality standards across regions make it imperative to go beyond just price comparisons. To effectively navigate these challenges, it is essential to establish clear communication channels with potential suppliers. Engage them in discussions about their manufacturing processes, quality control measures, and certifications. This direct interaction may reveal their commitment to quality and help you gauge their reliability.

Another effective strategy is to leverage industry networks and attend relevant trade shows. Connecting with other professionals in the textile industry can provide valuable insights into supplier performance. Participating in events focused on aramid fabric can also help you identify leading suppliers who are dedicated to innovation and quality. Additionally, always request samples and conduct rigorous testing before making bulk orders. This ensures that the products meet your specific requirements and allows you to assess the supplier's capability in meeting quality demands.

Furthermore, it’s beneficial to stay updated with market trends and technological advancements in aramid fabrics. By understanding the latest developments, you can make informed decisions when selecting suppliers who are not only reliable but also at the forefront of the industry. This proactive approach will ultimately lead to stronger partnerships and enhanced product quality.

When sourcing high-quality aramid fabrics globally, understanding the relevant quality standards and certifications is crucial. Aramid fabrics, known for their remarkable strength and resistance to heat and abrasion, are utilized in a variety of applications, including automotive tire reinforcement. Certifications such as ISO 9001, which focuses on quality management systems, help buyers ensure that manufacturers adhere to strict quality control processes. Additionally, recognizing industry-specific standards can further guide sourcing decisions, providing assurance of performance and durability.

Recent trends in the tire cord fabric market indicate a growing demand for advanced materials that enhance the durability and performance of automotive and industrial tires. As consumers increasingly prioritize safety and longevity in their vehicular choices, sourcing high-quality aramid fabric becomes essential. Ensuring that the fabric meets recognized quality standards not only boosts the product's reliability but also aligns with the expectations of modern consumers. By focusing on these certifications, sourcing professionals can confidently choose materials that will withstand the rigors of automotive applications, ultimately contributing to superior product performance in the competitive marketplace.

When sourcing high-quality aramid fabric, understanding geographic variation is crucial. Different regions may possess unique environmental factors, manufacturing practices, and raw material availability that can significantly influence the quality of finished fibers. For instance, countries with stringent textile regulations often produce superior aramid fabrics, as compliance guarantees quality control and sustainable practices.

One essential tip is to conduct thorough research on potential suppliers based on their geographic location. Look for regions known for their textile innovation and history, as this can be a good indicator of their capability to produce high-quality materials. Another tip is to visit manufacturing facilities whenever possible. This firsthand observation not only allows you to assess the manufacturing processes but also helps you establish relationships with suppliers, which can lead to better quality assurance.

Additionally, consider the supply chain logistics when sourcing aramid fabric globally. Understanding how the geographic location of suppliers affects shipping times and costs can inform your sourcing strategy. Proximity to raw material sources may also impact the freshness and stability of the fabric, ensuring a higher quality product. Balancing these geographic factors with your specific fabric requirements is essential for obtaining the best aramid fabric available.

When sourcing high quality aramid fabric globally, the balance between cost and quality can be a challenging yet crucial task. While it's tempting to go for the lowest price, compromising on quality can lead to increased costs in the long run due to product failures or customer dissatisfaction. Understanding the performance characteristics of aramid fabric is essential. Look for suppliers who provide detailed specifications and testing results; this will help ensure that you’re investing in a material that meets the necessary durability and thermal resistance standards.

One important tip is to assess the total cost of ownership rather than just the purchase price. Consider factors such as shipping costs, import duties, and the potential costs associated with poor quality. Another key consideration is vendor reliability. Establish relationships with suppliers who have a proven track record of delivering consistent quality. Regularly reviewing and establishing quality standards in your contracts will help align your expectations and safeguard against discrepancies.

Balancing price and performance requires diligence, but the right approach will lead to sustainable sourcing decisions that benefit your bottom line.

Navigating the complexities of trade regulations is crucial for sourcing high-quality aramid fabric globally. As companies engage in international procurement, it's essential to understand the various regulations that govern fabric imports and exports. Different countries impose specific tariffs, standards, and compliance requirements that can significantly impact the sourcing process. Researching the regulations of both the exporting and importing nations lays the groundwork for a smoother transaction and can help in avoiding potential legal issues that could arise due to non-compliance.

Additionally, keeping abreast of evolving trade agreements and potential trade wars is critical. These factors can alter market dynamics and affect price fluctuations in aramid fabric. Staying informed about changes in tariffs, import quotas, and material sourcing guidelines will empower companies to make informed decisions.

Partnering with experienced logistics and legal advisors can further streamline the sourcing process, ensuring that all regulatory nuances are respected. This comprehensive approach not only mitigates risks but also enhances the chances of securing high-quality aramid fabric that meets industry standards.