-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

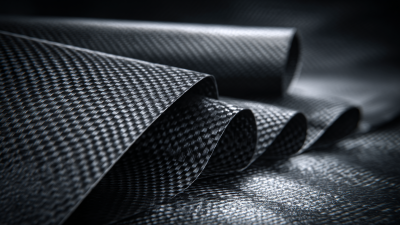

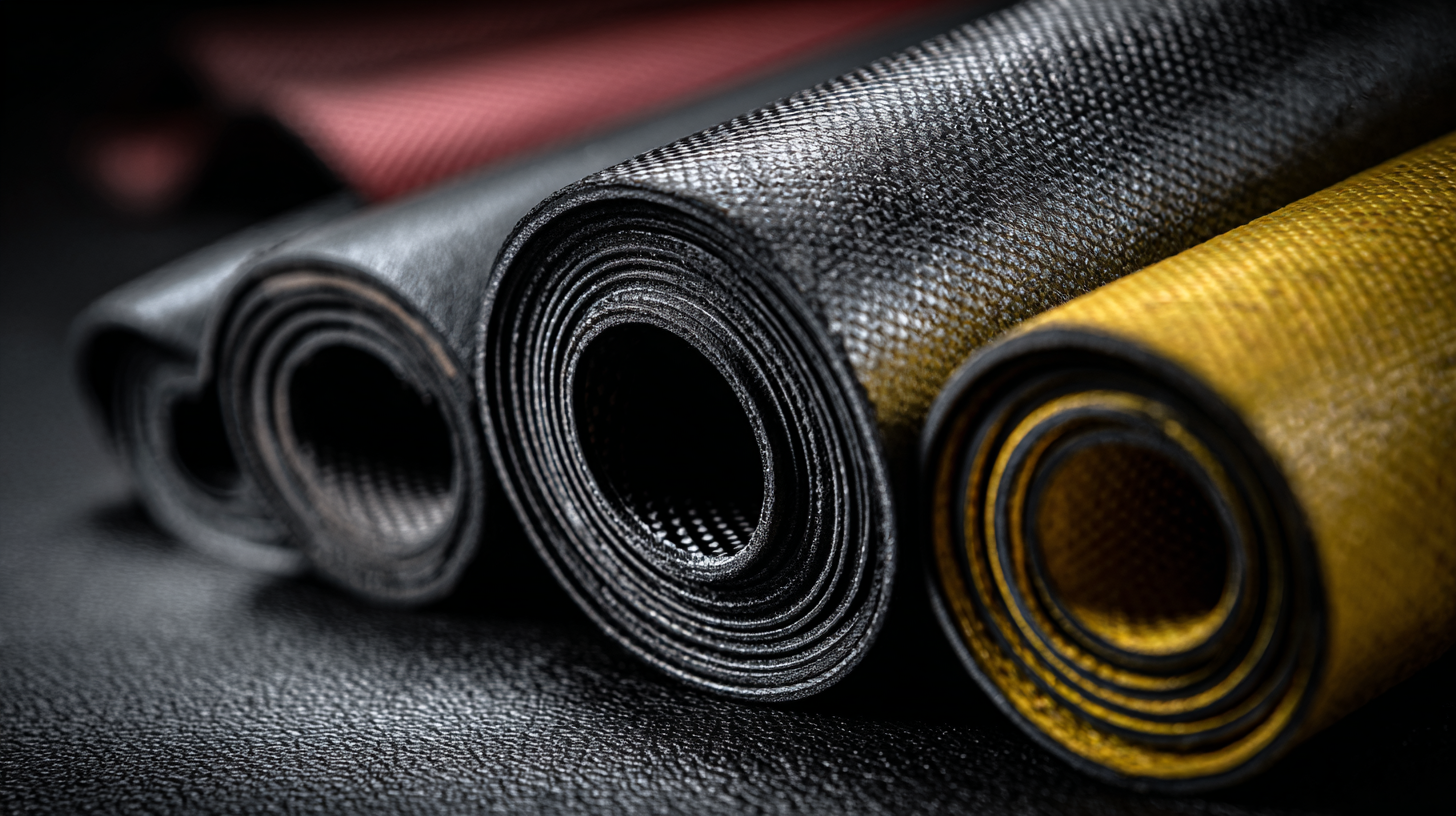

In the realm of modern design and engineering, the advent of innovative materials has revolutionized the way we create and construct. Among these,

Flexible Carbon Fiber Sheets stand out as a transformative solution that offers

unparalleled versatility and strength.

These lightweight yet durable sheets allow designers and engineers to push the boundaries of creativity and functionality, making them ideal for a wide range of applications—

from automotive components to architectural elements.

The ability to manipulate their form and incorporate them into various designs facilitates unique aesthetics and enhances performance characteristics, unlocking new potentials in industries that demand both elegance and resilience.

As we delve deeper into the applications, advantages, and future prospects of Flexible Carbon Fiber Sheets, it becomes clear that they are not just a material choice but a

catalyst for innovative design and engineering solutions.

The ability to manipulate their form and incorporate them into various designs facilitates unique aesthetics and enhances performance characteristics, unlocking new potentials in industries that demand both elegance and resilience.

As we delve deeper into the applications, advantages, and future prospects of Flexible Carbon Fiber Sheets, it becomes clear that they are not just a material choice but a

catalyst for innovative design and engineering solutions.

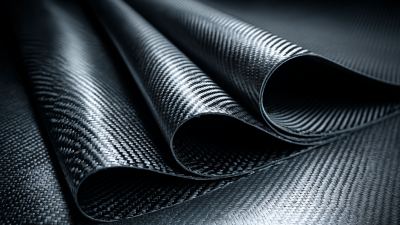

Flexible carbon fiber sheets are becoming increasingly prominent across various industries due to their remarkable versatility and innovative applications. As the nonwovens industry surges to a valuation of $70 billion with robust growth rates, the adaptability of materials like carbon fiber is quintessential in meeting the evolving demands of modern design and engineering. These sheets can be utilized in a wide array of applications, from automotive components requiring lightweight yet sturdy materials to aerospace innovations where performance and fuel efficiency are paramount.

One of the most exciting developments is the integration of robotic 3D manufacturing in fabricating these materials. By utilizing multiaxis articulators, designers can achieve unparalleled flexibility in part designs, allowing for greater complexity and improved production efficiencies. This technological synergy not only enhances the physical properties of flexible carbon fiber sheets but also streamlines the creation of intricate designs, paving the way for new possibilities in product development.

Tips: When exploring the use of flexible carbon fiber sheets, consider the specific requirements of your project, such as weight constraints and durability. Additionally, leveraging advanced manufacturing technologies can significantly improve the efficiency and effectiveness of your designs. Always stay updated on the latest industry trends to maximize the benefits of your material choices.

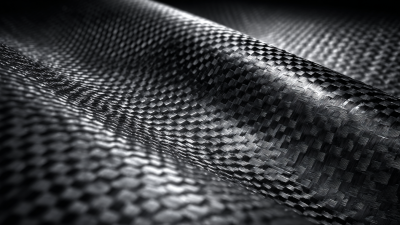

When considering the integration of flexible carbon fiber sheets in modern design and engineering, several key design considerations emerge. One of the most critical factors is the material's thermoformability. Recent advancements highlight the introduction of thermoformable carbon fiber, which alleviates traditional challenges related to scale and cost by automating many manual processes. This innovation not only enhances production efficiency but also facilitates high-volume manufacturing, enabling designers and engineers to explore intricate shapes and applications that were previously deemed impractical.

Another important consideration is the mechanical performance of carbon fiber-reinforced polymer sheets, particularly in critical applications such as seismic performance enhancements in steel structures. Research shows that varying bolt diameters can significantly influence the structural integrity of beam-column joints, underscoring the necessity for precision in design and selection. In addition, ongoing advancements in composite materials are leading to the development of lighter and more environmentally friendly alternatives, which can redefine traditional design paradigms. Such innovations prompt engineers to consider both performance and sustainability when selecting materials for new projects.

Flexible carbon fiber sheets are revolutionizing modern engineering, offering a unique combination of strength, lightweight properties, and adaptability. These innovative materials are increasingly being utilized in various applications, from automotive design to aerospace engineering. Their flexibility allows for intricate shapes and designs that were previously difficult to achieve with traditional materials, enabling engineers to push the boundaries of creativity and functionality.

In the automotive sector, flexible carbon fiber sheets are employed to enhance the performance and efficiency of vehicles. By using these sheets for body panels and structural components, manufacturers can reduce overall weight while maintaining structural integrity. This not only improves fuel efficiency but also enhances the vehicle's acceleration and handling characteristics. Similarly, in aerospace, the ability to mold carbon fiber sheets into complex geometries leads to significant weight savings and improved aerodynamic performance, contributing to the creation of cutting-edge aircraft that prioritize both performance and sustainability.

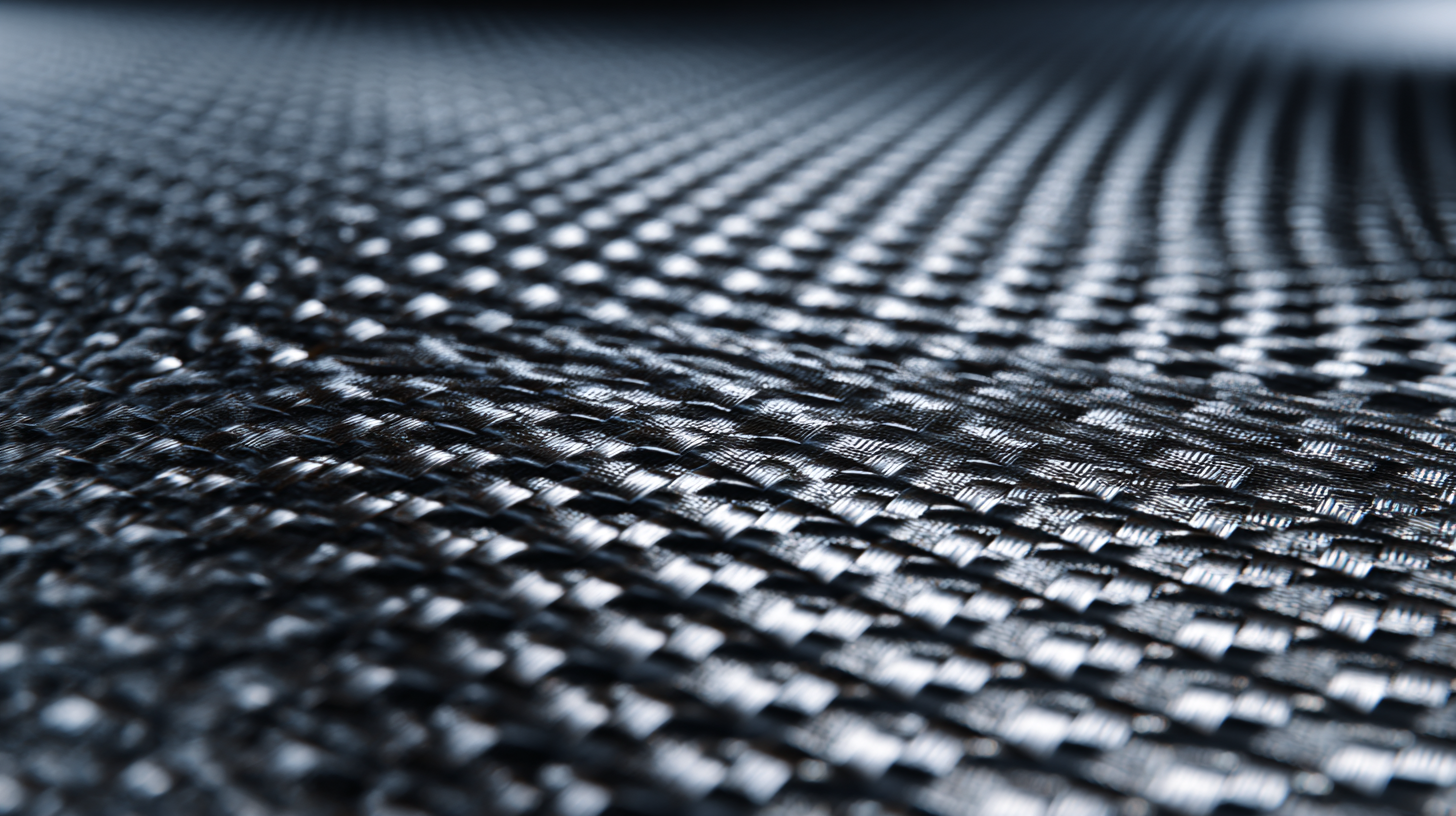

When working with flexible carbon fiber sheets, maximizing performance is key to harnessing their full potential in modern design and engineering. According to the Global Carbon Fiber Market report, the demand for carbon fiber materials is expected to increase by over 10% annually, driven by their superior strength-to-weight ratio and versatility in applications ranging from automotive to aerospace. To achieve optimal results, it is essential to understand the unique properties of carbon fiber, including its tensile strength of approximately 600 MPa, which surpasses that of conventional materials like aluminum.

One crucial tip for effectively handling carbon fiber materials is to ensure precise cutting techniques. Using specialized tools, such as carbide-tipped blades, can prevent fraying and ensure clean edges, leading to better bonding and structural integrity in final products. Additionally, the curing process is pivotal; maintaining a controlled environment during curing can significantly enhance the mechanical properties of composites. Industry studies have shown that a well-executed curing cycle can improve the overall strength of the composite by up to 30%. Therefore, investing time in these initial stages pays off by maximizing the performance and longevity of carbon fiber applications.

The evolving landscape of design and engineering is increasingly leaning towards cost-effective and sustainable materials, where flexible carbon fiber sheets are carving a niche. According to a report by Markets and Markets, the global carbon fiber market is projected to reach $5.67 billion by 2025, propelled by growing demand in automotive and aerospace applications. Flexible carbon fiber sheets provide an ideal solution, combining lightweight properties with impressive strength, making them cost-effective alternatives to traditional materials such as metals and plastics.

Sustainability is another significant aspect driving the adoption of carbon fiber in modern design. The material's recyclability is a critical advantage, with studies indicating that up to 94% of carbon fiber can be recycled, significantly reducing waste and environmental footprints. Furthermore, the production processes are evolving, with companies like Toray Industries working on reducing carbon emissions during manufacturing. As a result, flexible carbon fiber sheets not only enhance design capabilities but also align with sustainable practices essential for the future, making them a vital player in innovative engineering solutions.