-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

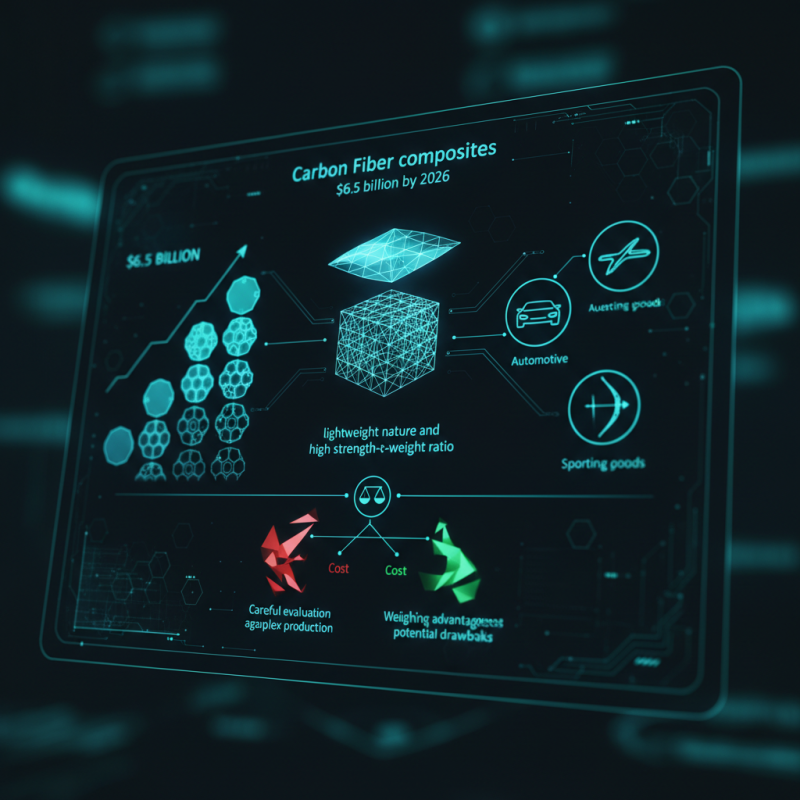

In recent years, Carbon Fiber Composites have gained significant attention across various industries. According to a 2022 market report by Research and Markets, the global carbon fiber composite market is projected to reach $6.5 billion by 2026. This growth is driven by their lightweight nature and high strength-to-weight ratio.

Manufacturers are increasingly opting for these materials to create components in aerospace, automotive, and sporting goods. However, choosing the right carbon fiber composites can be challenging. The variety of types, properties, and applications requires careful evaluation. Understanding specific performance needs is crucial for optimal selection.

While carbon fiber composites offer impressive benefits, they also present challenges. For instance, their cost can be a significant barrier for some businesses. Moreover, production processes can be complex and energy-intensive. Therefore, companies must reflect on their choices, weighing the advantages against potential drawbacks as they navigate this evolving landscape.

Carbon fiber composites have become increasingly popular due to their unique properties. They are lightweight yet incredibly strong. In fact, their strength-to-weight ratio can be five times that of steel. This makes them ideal for various industries, such as aerospace and automotive.

A key characteristic of carbon fiber composites is their resistance to corrosion and fatigue. Unlike metals, they do not rust. This longevity can lead to lower maintenance costs over time. Data from industry reports suggest that using carbon fiber can improve fuel efficiency in vehicles by 20%. This is a significant factor in today’s environmental focus. However, the production process is not without challenges. It requires high energy input and careful handling.

Another aspect to consider is the composites' thermal properties. They can withstand extreme temperatures. However, the tricky part is their conductiveness. Some applications may require non-conductive materials. Balancing these characteristics can be complex. As industries evolve, developing the right composites becomes crucial. Future innovations must address these challenges to maximize benefits.

Understanding the key characteristics and benefits of carbon fiber composites can help in making the right choice for various applications. The following chart illustrates the comparison of different types of carbon fiber composites based on their density, tensile strength, and cost per kilogram.

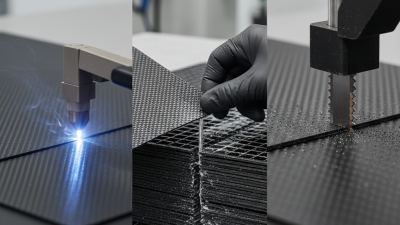

When choosing carbon fiber composites, understanding their types is essential. These materials vary significantly in strength, weight, and cost. There are two primary types: woven and unidirectional. Woven composites offer flexibility and ease of handling, while unidirectional composites provide higher strength and stiffness in one direction. This can be crucial for applications in aerospace and automotive industries.

Research shows that the demand for carbon fiber composites will exceed $30 billion by 2027. This growth highlights the importance of selecting the right composite for specific needs. For instance, aerospace-grade composites require superior tensile strength and thermal resistance. On the other hand, sporting goods may prioritize a balance between weight and cost.

Tips: Consider the environment where the composite will be used. High humidity can weaken some types. Test different options to determine which fits best. Always consult technical data sheets to ensure compatibility with your projects. Reflect on the long-term implications; while cheaper options exist, they may not yield durable results. Balancing cost with performance is a critical aspect of selection.

Choosing the best carbon fiber composites for your project can be challenging. The right selection depends on various criteria that cater to your specific needs. First, consider the material properties. Carbon fiber composites offer different strengths and stiffness levels. Make sure to assess the required tensile strength and modulus.

Next, think about the weight-to-strength ratio of the composites. Lighter options might be suitable for high-performance applications like aerospace. However, they may lack durability in heavy-duty environments. Conduct tests or consult with experts before making a final decision.

Tips: Always ask for samples. This allows you to evaluate the material's feel and flexibility. Pay attention to the fiber orientation too. Different orientations can affect the overall performance. Also, explore the price range. A high-cost composite might not always be the best fit for your budget. Reflect on these factors to make an informed choice.

When choosing carbon fiber composites, performance and durability are key factors. High-performance composites can withstand stress and impact. They are lightweight yet strong, making them ideal for various applications. However, not all carbon fiber materials are created equal.

Consider the composite's tensile strength. This indicates how much force it can handle before breaking. The higher the tensile strength, the better it will perform under pressure. Another factor is the impact resistance. These composites may resist fractures and maintain integrity during sudden impacts.

Tips: Always check the manufacturer's specifications. Look for third-party testing results. Don't rely solely on marketing claims. Evaluate past performance data. It’s useful to seek feedback from users who have tested these materials.

Durability is often tied to environmental factors. Carbon fiber can suffer from UV exposure and moisture. Choosing a composite with protective coatings might be necessary. Consider fibers that retain strength over time. Yet, there’s still room for improvement in this area. Testing different composites can lead to discoveries of best use cases. Remember, every application may result in different performance outcomes.

| Composite Type | Tensile Strength (MPa) | Flexural Modulus (GPa) | Weight (kg/m3) | Durability (Years) | Cost ($/kg) |

|---|---|---|---|---|---|

| Standard Carbon Fiber | 550 | 80 | 1600 | 15 | 30 |

| High Modulus Carbon Fiber | 700 | 120 | 1550 | 20 | 45 |

| Aramid Fiber Reinforced | 600 | 90 | 1700 | 18 | 35 |

| Epoxy Carbon Composites | 570 | 85 | 1650 | 12 | 28 |

| Ultra-High Performance Carbon Fiber | 900 | 130 | 1500 | 25 | 60 |

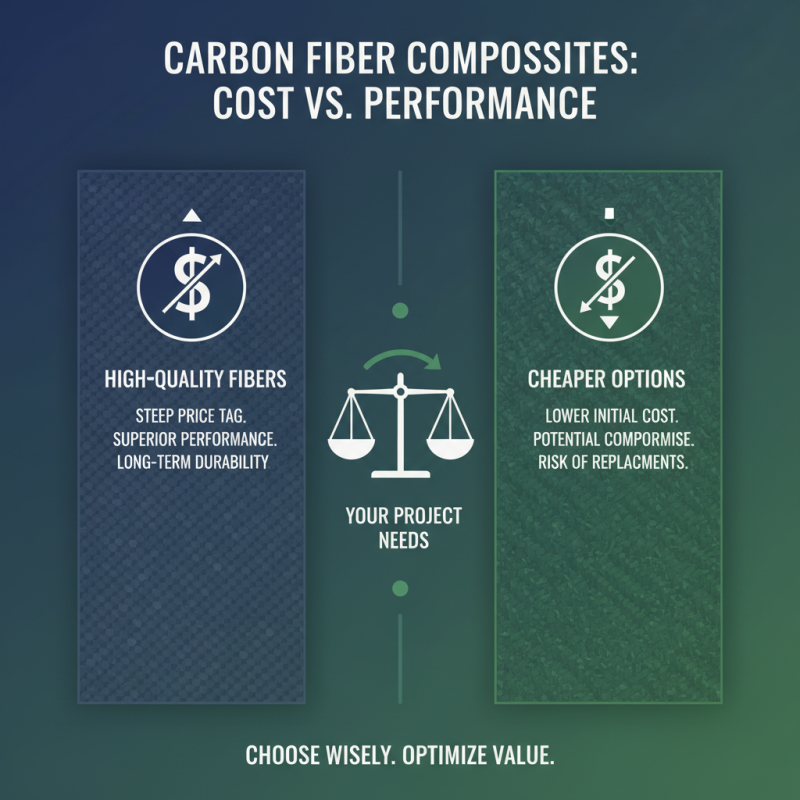

When evaluating carbon fiber composites, cost is a crucial factor. The price can vary significantly based on the type of carbon fiber used and the manufacturing process. Higher-quality fibers often come with a steep price tag. However, cheaper options may compromise performance. It’s important to assess what you truly need for your project. Sometimes, the initial savings could lead to costly replacements down the road.

Additionally, consider the long-term value. While upfront costs matter, think about durability and maintenance. Lower-cost options may degrade faster, resulting in additional expenses. Budgeting for the entire lifespan of the composite is essential. Also, keep in mind that source and availability can impact overall pricing. If you're in a pinch, rushing decisions could lead to poor choices. Always weigh immediate benefits against future implications.