-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the realm of repair solutions, the emergence of innovative materials has revolutionized our approach to restoring and enhancing the durability of various objects. One such material that has gained significant attention is Carbon Fiber Tape. Renowned for its exceptional strength-to-weight ratio and impressive tensile properties, Carbon Fiber Tape offers a versatile and effective means of conducting repairs that are both robust and long-lasting. This introduction aims to delve into the myriad applications of this remarkable tape, highlighting its unique benefits for tackling repairs across a wide spectrum of items.

From everyday household items to specialized equipment, Carbon Fiber Tape serves as a reliable ally in reinforcing structures and preventing further damage. Whether addressing minor fractures or enhancing the integrity of components, utilizing Carbon Fiber Tape can significantly elevate the effectiveness of repair efforts. As we explore the practical methods for employing this material, we will uncover essential techniques and tips that ensure optimal results, enabling users to harness the full potential of Carbon Fiber Tape for diverse repair applications.

Carbon fiber tape is an innovative material that has gained popularity in various repair applications due to its exceptional strength and durability. This tape is made from strands of carbon fiber, renowned for their lightweight properties and high tensile strength. As a result, carbon fiber tape offers a unique solution for reinforcing and repairing structures, whether they are mechanical components, sporting equipment, or household items. The ability to withstand extreme conditions without losing its integrity makes it an ideal choice for both temporary fixes and permanent solutions.

One of the key benefits of carbon fiber tape is its versatility. It can conform to a variety of shapes and surfaces, making it suitable for different repair scenarios. This flooring could be used in applications ranging from automotive repairs, where it withstands heat and stress, to home repairs, adding structural integrity to weakened areas. Additionally, carbon fiber tape is resistant to moisture and chemicals, ensuring long-lasting repairs that can endure harsh environments. As the demand for efficient and reliable repair solutions grows, carbon fiber tape stands out not only for its performance but also for its ease of use, allowing both professionals and DIY enthusiasts to achieve high-quality results without extensive tools or skills.

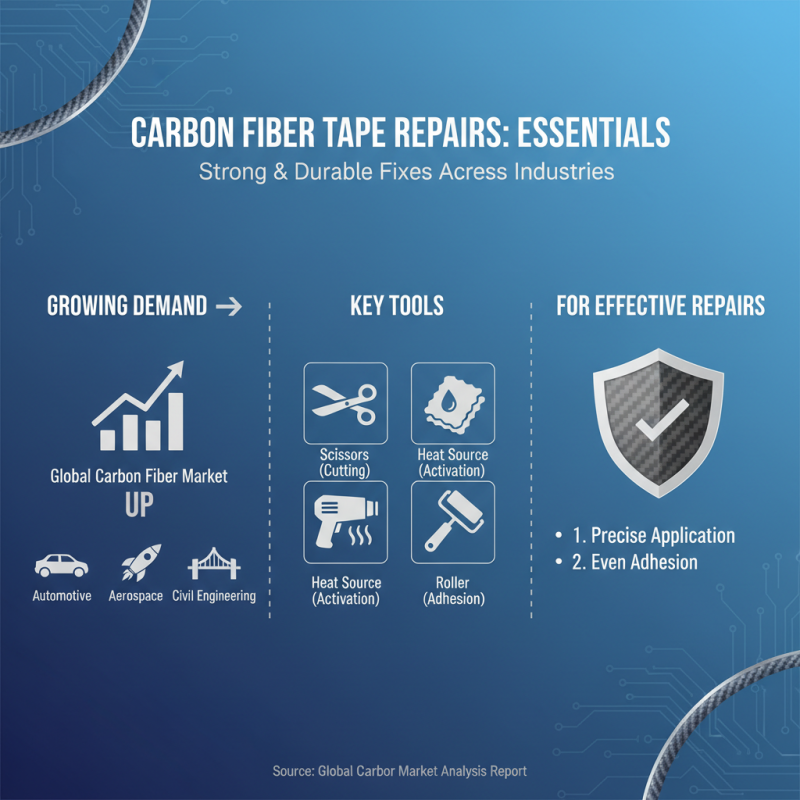

When utilizing carbon fiber tape for repairs in a variety of applications, having the right tools and materials is crucial for achieving strong and durable results. According to a report by the Global Carbon Fiber Market Analysis, the demand for carbon fiber products is projected to grow significantly, highlighting its increasing presence in industries such as automotive, aerospace, and civil engineering. For effective repairs, one should gather essential tools including scissors for precise cutting, a heat source for activating adhesive properties, and a clean cloth for surface preparation. Additionally, a roller can be beneficial for ensuring that the tape adheres completely and evenly to the surface being repaired.

In terms of materials, it is critical to select high-quality carbon fiber tape, which typically consists of woven strands of carbon fiber providing both strength and lightness. The properties of carbon fiber allow it to withstand high stress and temperature fluctuations, making it ideal for various applications—from minor household fixes to extensive industrial repairs. Industry data suggests that repairs utilizing carbon fiber tape can achieve strength-to-weight ratios of over 100:1, showcasing its superiority compared to traditional repair materials. Furthermore, proper surface preparation and curing processes will enhance the bond strength, ensuring longevity and reliability of the repairs conducted with carbon fiber tape.

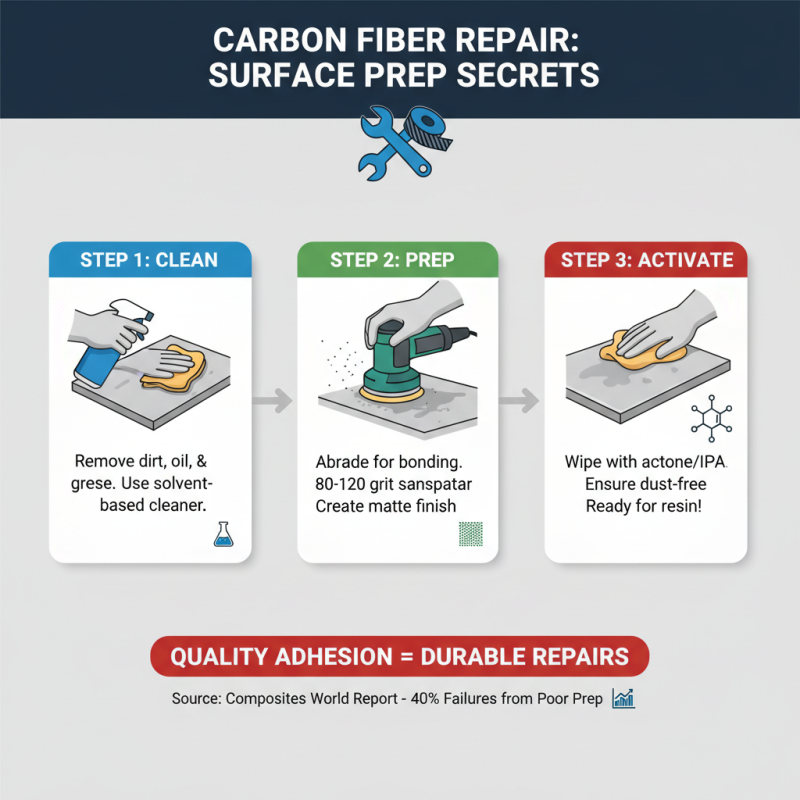

Preparing the surface for carbon fiber tape repairs is crucial for ensuring strong and durable results. According to a report by the Composites World, improper surface preparation is one of the leading causes of repair failures, accounting for nearly 40% of all issues in composite repairs. To achieve the best adhesion, the first step involves thoroughly cleaning the surface to remove any contaminants such as dirt, oil, or grease. Utilizing a solvent-based cleaner can effectively eliminate residues, as recommended in industry standards.

Once the surface is cleaned, the next step is surface roughening. Research published by the Journal of Materials Science indicates that increasing the surface area through mechanical abrasion improves the bonding capabilities of carbon fiber tape. Light sanding with a fine-grit sandpaper can create micro-abrasions, enhancing the tape's grip. It is essential to wipe away any dust generated from the sanding process using a lint-free cloth to ensure the surface remains clean. Following these steps will provide an optimal foundation for applying carbon fiber tape, significantly enhancing the repair's overall strength and durability.

When it comes to applying carbon fiber tape for repairs, mastering the right techniques can make a significant difference in the durability and effectiveness of your fixes. First, preparing the surface is crucial. Ensure that the area is clean and dry, free from any dirt, grease, or previous adhesive residues. Use sandpaper or a suitable abrasive to lightly scuff the surface, which enhances adhesion by providing a better grip for the tape. Once prepared, cut the carbon fiber tape to the desired length, leaving some extra length on either side for effective bonding.

When applying the tape, it’s essential to work methodically. Start from one end of the repair area and apply the tape in a smooth, even manner, avoiding air pockets or wrinkles. It’s beneficial to use a roller or a flat tool to firmly press the tape down as you apply it, ensuring that the fibers bond well with the surface. For optimal results, consider layering strips of tape for added strength, especially in areas that will undergo stress or pressure. Allow sufficient curing time as indicated in your guide for the adhesive, as this step is vital for the longevity of the repair.

When working with carbon fiber tape for repairs, the curing and finishing process is critical to achieving maximum strength and durability. According to industry standards, the optimal curing temperature for carbon fiber resin systems is typically between 60°C to 80°C (140°F to 176°F), which allows the resin to properly harden and bond with the substrate material. This temperature range not only enhances the adhesive properties of the tape but also minimizes the risk of air bubbles forming during the curing process, which can significantly weaken the bond.

Once the initial curing phase is complete, finishing touches can further amplify the repair’s integrity. Surface preparation, such as sanding the repaired area lightly, creates a micro-texture that encourages better mechanical bonding of subsequent layers of resin or sealants. A recent study published in the Journal of Composite Materials indicates that repairs utilizing proper finishing techniques can increase the overall strength of the adhesive bond by up to 40%. Additionally, applying a protective topcoat after the curing process can safeguard the repair from environmental factors, enhancing its longevity. With correct application procedures and attention to detail during the curing and finishing stages, the use of carbon fiber tape can yield robust, lasting repairs suitable for various high-strength applications.