-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

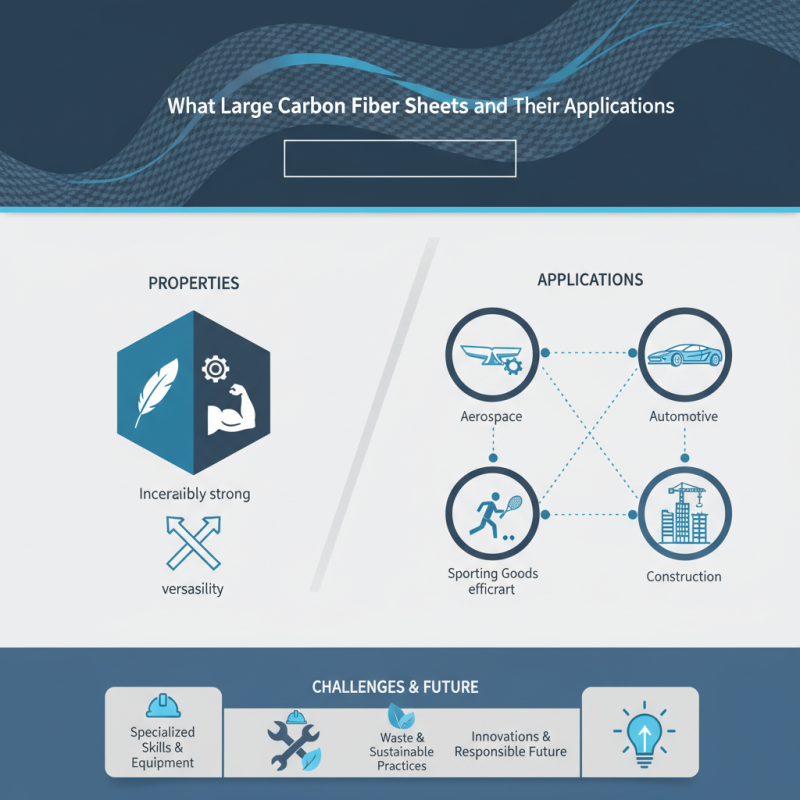

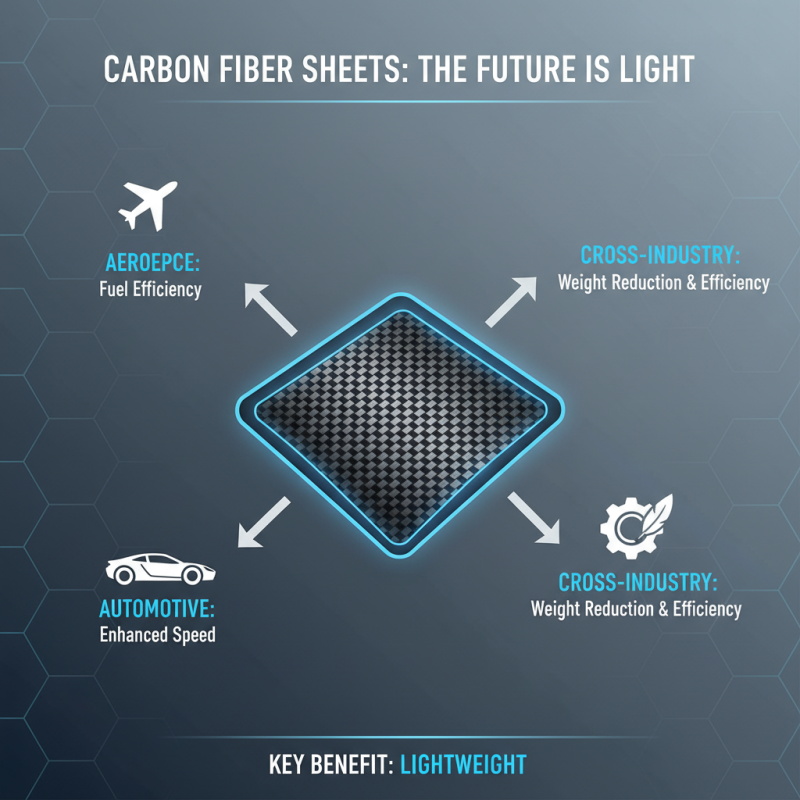

Large Carbon Fiber Sheets have transformed various industries with their unique properties. These sheets are lightweight but incredibly strong, making them ideal materials for multiple applications. Many businesses are now exploring how these large sheets can enhance their products and processes.

In aerospace, Large Carbon Fiber Sheets play a crucial role in building lighter and more fuel-efficient aircraft. Automotive manufacturers use them too. They contribute to making cars more efficient and better-performing. The versatility of these sheets extends to sporting goods and construction, proving their adaptability.

However, it’s essential to recognize the challenges. Working with Large Carbon Fiber Sheets requires specialized skills and equipment. Waste during production is another concern. As industries grow, finding sustainable practices is vital. Innovations and adjustments will pave the way for a responsible future with these materials.

Large carbon fiber sheets are composite materials made from woven fibers and polymer resins. They are known for their high strength-to-weight ratio. This makes them ideal for various industrial applications. The global carbon fiber market is expected to grow considerably. Reports suggest a growth rate of around 9% annually.

These sheets are often utilized in the aerospace and automotive industries. For instance, they provide lightweight solutions that enhance fuel efficiency. Also, they offer greater durability compared to traditional materials. However, their production process can be complex. It often requires significant investment and specialized knowledge, which some companies may lack.

In construction, large carbon fiber sheets are gaining popularity. Their application in reinforcing structures can help reduce weight while maintaining structural integrity. Yet, the cost remains a challenge for widespread use. Some may find the price prohibitive. As the market evolves, better technologies could emerge, potentially addressing these concerns and expanding their applications.

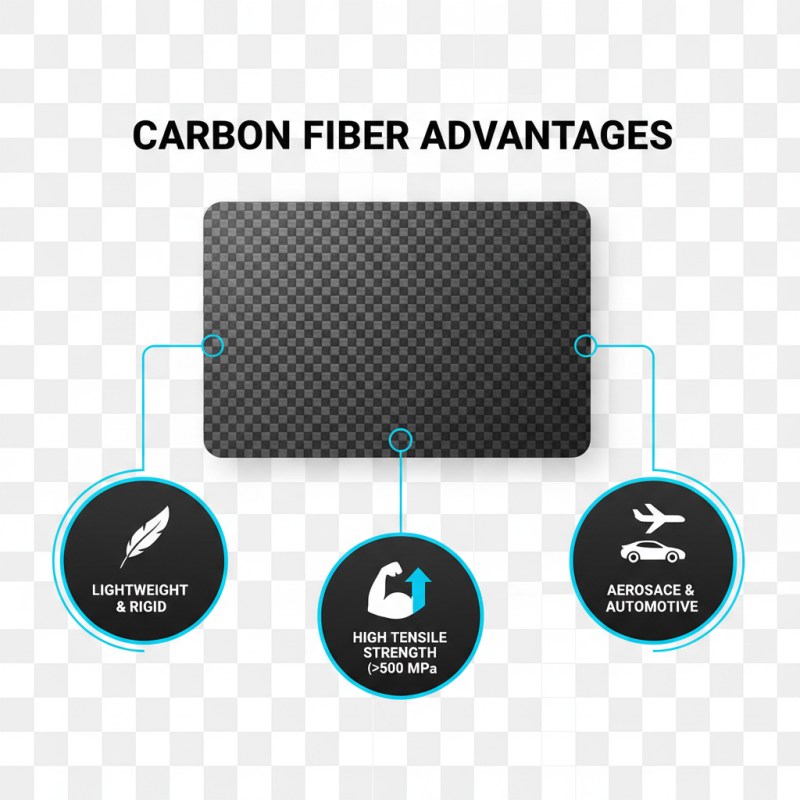

Large carbon fiber sheets have garnered significant attention in various industries. Key properties make them highly desirable. They are lightweight yet strong. This material provides high tensile strength, often exceeding 500 MPa, which is critical in aerospace and automotive applications.

Moreover, carbon fiber sheets have excellent stiffness-to-weight ratios. For instance, their modulus of elasticity typically ranges from 70 GPa to 300 GPa. This means structures can be both light and rigid. Additionally, they exhibit remarkable resistance to fatigue and corrosion, ensuring longevity in demanding environments. These attributes are essential in creating durable components.

However, not everything is perfect with large carbon fiber sheets. The manufacturing process can be complex and costly. Quality control remains a challenge, impacting consistency in production. Despite advancements, the recycling of carbon fiber is still limited. This presents an ongoing issue for sustainability. Balancing performance and environmental impact is crucial for future developments.

Large carbon fiber sheets are increasingly utilized in various industries due to their unique properties. These sheets are lightweight yet incredibly strong. They provide high stiffness and low thermal expansion, making them ideal for applications in aerospace and automotive sectors.

In the aerospace industry, large carbon fiber sheets are essential for aircraft construction. They reduce weight significantly, leading to improved fuel efficiency. A report by the National Aerospace and Defense Contractors Accreditation Program highlights that carbon fiber can cut aircraft weight by up to 30%. This results in substantial cost savings for airlines. However, the manufacturing process is complex and requires careful quality control. Any flaw can lead to potential safety issues.

The automotive industry also benefits from these materials. Large carbon fiber sheets are used in high-performance vehicles, enhancing speed and performance. A study shows that using carbon fiber can improve a car's performance by over 15%. Yet, the high cost of raw materials poses a challenge. Manufacturers must balance expenses with the benefits. This reliance on carbon fiber raises questions about long-term sustainability as well.

Large carbon fiber sheets have gained popularity in various industries. Their lightweight nature is a major advantage. These sheets significantly reduce the overall weight of products. This can lead to improved efficiency, especially in aerospace and automotive applications. Reduced weight helps in saving fuel and enhancing speed.

The strength of large carbon fiber sheets is another key benefit. They offer high tensile strength compared to traditional materials like aluminum or steel. This means they can withstand greater forces without bending or breaking. In construction, using these sheets can result in safer buildings. They are also corrosion-resistant, which prolongs their lifespan in harsh environments.

However, challenges exist. Manufacturing large sheets can be costly. The initial investment might discourage some businesses. Additionally, recycling carbon fiber is still a developing field. It raises questions about environmental impact. As industries look for alternatives, these considerations will shape future development in materials. Exploring the balance between benefits and challenges is essential.

The evolution of carbon fiber sheet technology holds immense potential. As industries seek lightweight and durable materials, innovations continue to emerge. Researchers focus on enhancing the strength-to-weight ratio, leading to new applications. These sheets could revolutionize aerospace, automotive, and sporting goods.

Recent advancements involve better resin systems and production techniques. Innovations in manufacturing processes may drive down costs. However, some challenges remain. Production methods need further optimization to reduce waste and energy consumption. Sustainability is a key consideration in future developments.

In terms of applications, we see a promising shift. Engineers explore the use of large carbon fiber sheets in construction and renewable energy sectors. The need for materials that withstand harsh environments is growing. Nonetheless, the scalability of production is still a concern. As we look to the future, the balance between innovation and practicality will be essential to maximize the potential of carbon fiber sheets.

| Application Area | Benefits | Future Trends | Innovation Potential |

|---|---|---|---|

| Aerospace | Weight reduction, enhanced fuel efficiency | Use of bio-based resins | Advanced structural designs |

| Automotive | Improved performance, crash safety | Increased recycling initiatives | Smart material integration |

| Sporting Goods | Enhanced performance and durability | Customization through 3D printing | Personalized gear technology |

| Construction | Increased structural strength, lightweight | Sustainability in building materials | Integration with IoT for monitoring |

| Medical Devices | Biocompatibility, lightweight | Advanced imaging technologies | Smart diagnostic tools |