-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In an era where safety and precision are paramount in various industries, the demand for innovative protective materials has surged. According to a recent market analysis by Research and Markets, the global protective clothing market, including cut-resistant fabrics, is projected to reach $13.74 billion by 2027, growing at a CAGR of 6.3% from 2020. Among these advancements, "Cut Proof Fabric" has emerged as a game-changer for professionals and artisans alike, providing essential protection against sharp edges and hazardous materials. This ultimate guide will explore the techniques and applications of cut proof fabric, enabling you to master its use in your projects for unparalleled safety and efficiency. By understanding its properties and correct implementation, you can enhance your work environment and contribute to a culture of safety, ensuring both your well-being and the quality of your output.

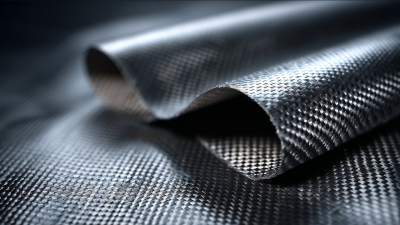

Cut-proof fabrics are becoming increasingly essential across various industries, particularly in sectors where safety is a paramount concern, such as construction, healthcare, and outdoor activities. These innovative materials utilize advanced technologies and high-performance fibers like Kevlar and Dyneema, which are known for their exceptional cut-resistance properties. According to recent industry reports, the cut-resistant gloves market is expected to grow significantly, projected to reach over $2.4 billion by 2027. This surge is driven by heightened awareness of workplace safety and advancements in fabric technology that enhance protection without sacrificing comfort and dexterity.

Moreover, the rise in demand for cut-proof fabrics has also influenced consumer products, notably in travel gear. Anti-theft backpacks featuring slash-proof fabric have been gaining popularity, with lab tests highlighting their effectiveness against the growing threat of theft during travel. These backpacks often incorporate steel wire mesh within the fabric, significantly reducing the risk of theft while maintaining the flexibility and style expected by modern travelers. Industry experts predict that by 2025, we will see a notable increase in fabric innovations, focusing on both enhanced safety features and sustainability, paving the way for responsible manufacturing in a competitive market.

Cut proof fabrics have gained significant recognition in various industries, particularly in environments where safety is paramount, such as manufacturing and food processing. One of the primary advantages of these materials is their ability to reduce the risk of cuts and abrasions, which can lead to serious injuries. Designed with advanced fibers that resist sharp objects, cut proof fabrics provide an essential layer of protection for workers handling hazardous tools or materials. This enhanced safety feature not only safeguards employees but also contributes to a more efficient workplace, as fewer injuries mean less downtime and lower medical costs.

Moreover, the integration of cut proof fabrics into work attire and equipment design promotes a culture of safety within organizations. When employees feel secure in their protective gear, their overall productivity increases. Innovations in cut resistant technologies not only improve flexibility and comfort but also ensure that these fabrics can be easily maintained and tailored to specific industries. Thus, incorporating cut proof fabrics into daily operations is a forward-thinking approach that not only prioritizes safety but also enhances performance and morale in the workplace.

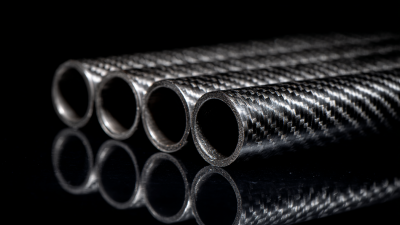

When working on projects that involve potential cutting hazards, understanding industry standards for cut-proof materials is essential. Cut-proof fabrics are designed to provide enhanced protection against sharp objects, and they come in various types, each suited for specific applications. The most commonly used materials include Kevlar, Dyneema, and stainless steel mesh, which offer different levels of resistance based on their construction and intended use. Familiarizing yourself with these materials and their properties can significantly influence the safety of your work environment.

Compliance with industry standards such as ISO 13997 and EN 388 is crucial when selecting cut-proof fabrics. These standards provide guidelines for testing the cut resistance of materials, ensuring they meet specific safety benchmarks. For example, ISO 13997 measures the force required to cut through a material using a standardized blade, while EN 388 assesses overall abrasion, blade cut, tear, and puncture resistance. By adhering to these standards, you ensure that you are utilizing the most reliable fabrics available, ultimately enhancing the safety and efficacy of your projects.

In today's rapidly evolving industrial landscape, the investment in cut-resistant solutions is becoming increasingly crucial for ensuring safety and efficiency in various projects. A recent analysis indicates that the global market for cut-resistant fabrics is projected to reach approximately $7 billion by 2025, driven by the growing demand across several sectors including healthcare, automotive, and construction. This significant growth reflects not just an increase in safety measures but also a responsive adaptation to innovation capabilities seen in markets such as China, where advancements in material technology are being prioritized.

Moreover, as organizations in the United States and globally navigate economic uncertainties, a cost-benefit analysis of cut-resistant solutions highlights that the initial investment can lead to substantial long-term savings. By reducing workplace injuries, companies can minimize compensation costs and improve overall productivity. The chemical industry, which is forecasted to emphasize sustainability and innovation in the coming years, serves as a model for exploring cost-effective strategies that integrate safety without compromising on quality or performance. The investment in advanced protective materials can thus be viewed as not just essential for worker safety, but as a strategic allocation of resources that supports broader economic resilience and growth.

Cut proof fabrics are revolutionizing safety across various sectors, providing essential protection against sharp objects and cutting hazards. In the medical field, for instance, these innovative materials are increasingly used in surgical gowns and gloves, ensuring that healthcare workers remain safe from accidental cuts while handling surgical tools. This not only enhances worker safety but also contributes to better overall hygiene and reduces the risk of infection in sterile environments.

In the manufacturing and construction industries, the application of cut proof fabrics is equally transformative. Workers are often exposed to sharp tools and materials, raising the importance of protective clothing. By integrating cut resistant textiles into uniforms and gloves, companies can significantly lower the rate of workplace injuries. Furthermore, these fabrics are being embraced in the automotive sector for protective gear, ensuring that workers are well-equipped to handle components that may have sharp edges.

The versatility of cut proof fabrics enables their use in everyday applications as well. For instance, outdoor enthusiasts can benefit from these materials in items such as gloves and apparel designed for activities like rock climbing or lumberjack work, where the risk of cuts is prevalent. By blending innovation with practicality, cut proof fabrics are redefining safety standards across multiple industries, offering peace of mind without compromising on comfort or functionality.

| Sector | Application | Type of Cut Proof Fabric | Benefits |

|---|---|---|---|

| Healthcare | Surgical Gowns | Dyneema Composite | High resistance to cuts, lightweight, breathable |

| Construction | Worker Safety Gloves | Kevlar | Excellent cut resistance, durable and flexible |

| Automotive | Interior Upholstery | Cut Resistant Textile Blend | Resists wear and tear, enhances passenger safety |

| Food Processing | Protective Clothing for Workers | High-Performance Polyethylene | Protects against cuts from knives and sharp tools |

| Sports | Protective Gear for Athletes | Ultra-high Molecular Weight Polyethylene (UHMWPE) | Enhances safety without sacrificing mobility |