-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

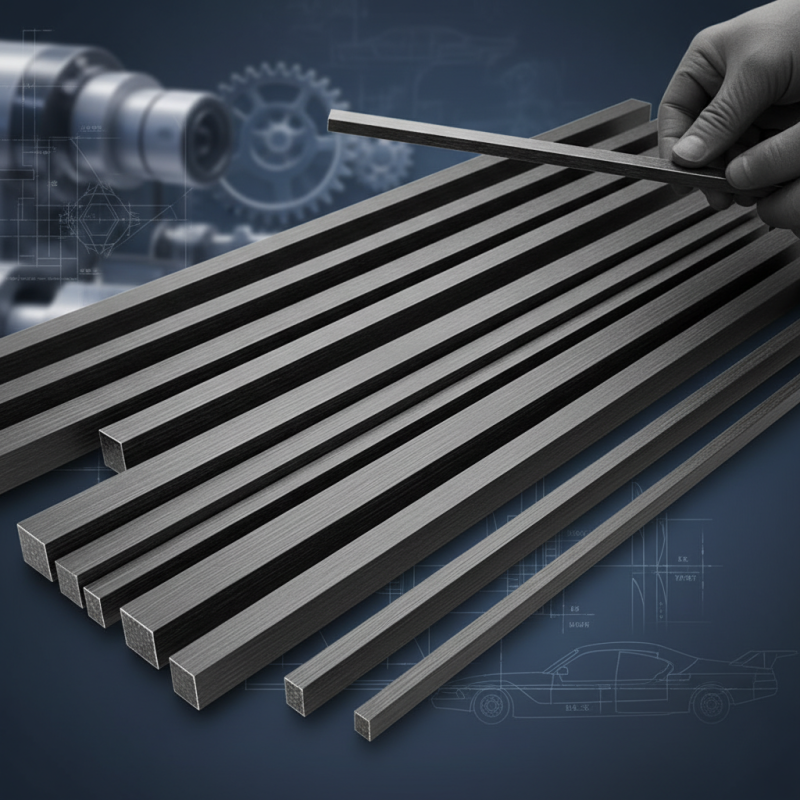

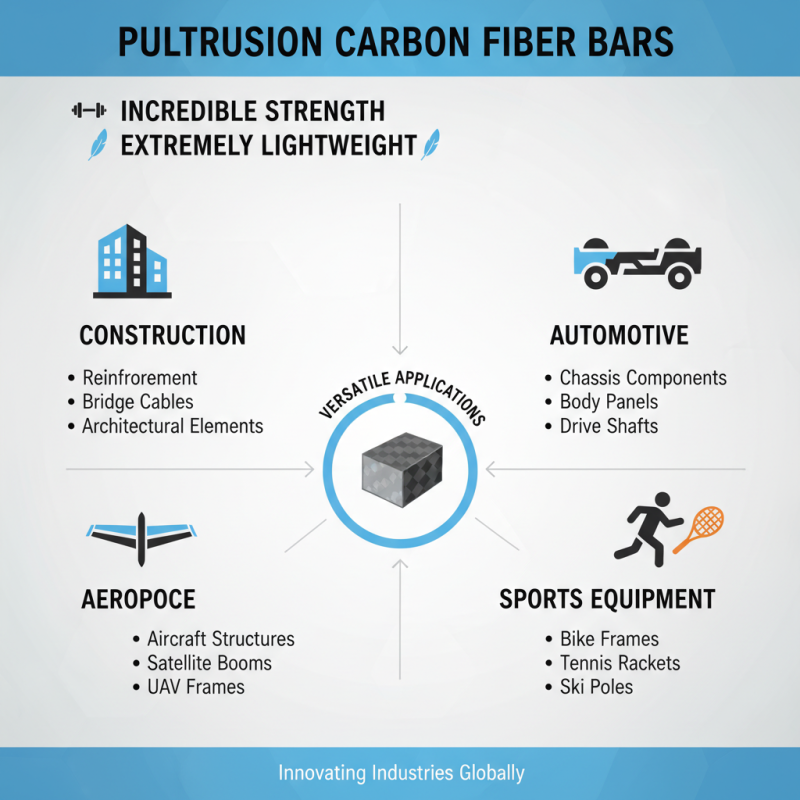

The Pultrusion Carbon Fiber Bar is gaining attention in various industries. Experts highlight its strength and lightweight properties. Dr. Emily Richards, a leading figure in composite materials, states, “The versatility of Pultrusion Carbon Fiber Bars makes them essential for modern engineering.”

These bars offer numerous benefits. Their high tensile strength allows for sturdy constructions. Engineers appreciate their ability to resist corrosion. Furthermore, these bars can be molded into various shapes, enhancing design flexibility. Yet, some challenges exist. The initial cost may deter small businesses.

Understanding the applications and advantages of Pultrusion Carbon Fiber Bars is crucial. They are transforming sectors like automotive and aerospace. However, ongoing research and innovation are needed. Overall, they present a significant opportunity, despite some hurdles.

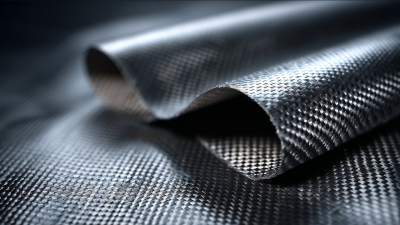

Pultrusion carbon fiber bars are lightweight yet incredibly strong composite materials. They are produced through the pultrusion process, which involves pulling raw fiber through a resin bath. This method creates a continuous, uniform structure. Research indicates that these bars have a tensile strength exceeding 600 MPa, making them suitable for various high-performance applications.

The advantages of pultrusion carbon fiber bars are significant. They resist corrosion, minimizing maintenance costs. This is crucial in industries that operate in harsh environments. According to industry data, up to 75% of structures made with carbon fiber can last longer than traditional materials. However, the production process can be energy-intensive, raising questions about overall sustainability. Manufacturers must evaluate this aspect carefully.

Despite their benefits, pultrusion carbon fiber bars are not without issues. The initial cost remains high, which can deter some projects. Additionally, there is a learning curve in working with these materials. Not all engineers and contractors are familiar with their properties. This gap in knowledge can lead to suboptimal designs. Exploring these factors is essential for maximizing the potential of pultrusion carbon fiber bars.

The manufacturing process of pultrusion for carbon fiber bars is a fascinating technique. Pultrusion combines continuous fibers with a thermosetting resin, resulting in strong and lightweight components. The process begins with fiber strands being pulled through a resin bath, saturating them thoroughly. Then, they enter a heated die, where the resin cures. Temperature and timing are critical here, as they directly affect the properties of the finished product.

Industry reports indicate that pultrusion can achieve a very high strength-to-weight ratio, often exceeding 100 MPa in tensile strength. This is particularly useful in applications demanding durability without excessive weight. Despite its advantages, the pultrusion process has challenges. One common issue is ensuring consistent fiber alignment. Misalignment can compromise strength, leading to potential failures. It’s crucial for manufacturers to refine their techniques continuously. The focus on minimizing defects is vital for the industry's growth.

Moreover, the production speed of pultrusion can sometimes be a double-edged sword. Rapid output can lead to reduced quality control. A study found that only 75% of products met rigorous industry standards when rushed. Balancing speed and quality is an ongoing struggle in the field.

Carbon fiber bars offer impressive properties that enhance various applications. They are lightweight yet incredibly strong. This unique combination makes them a popular choice in construction and automotive industries. Carbon fiber bars resist corrosion, which extends their lifespan. They can withstand harsh environments without significant wear.

Moreover, these bars exhibit excellent tensile strength. This means they can endure significant forces without breaking. Their flexibility is another key trait. This allows for design versatility in various engineering projects. Unfortunately, the manufacturing process can sometimes introduce defects. It may require careful inspection to ensure quality.

Additionally, carbon fiber bars have low thermal expansion. They maintain their shape and size under varying temperatures. This stability makes them ideal for precision instruments. However, the cost of production is often high. This can limit their use in some scenarios. Overall, understanding these key characteristics can help guide better material choices.

Pultrusion carbon fiber bars are making waves across various industries. Their strength and lightweight properties are highly beneficial. You can find them in construction, automotive, aerospace, and sports equipment. Each sector leverages these bars for specific needs.

In construction, they are used for structural components. The durability helps reduce maintenance costs. However, some designs can be tricky. Not every design optimizes the material’s strength. It’s vital to test different configurations.

Tips: Consider the environmental impact of your choice. Carbon fiber has a high recycling potential, yet it’s often overlooked. Always seek ways to enhance sustainability.

In the automotive industry, pultrusion carbon fiber bars improve fuel efficiency. The reduced weight leads to better performance. Yet, the initial cost can be high. That might deter some manufacturers. Identify the long-term savings to justify the expense.

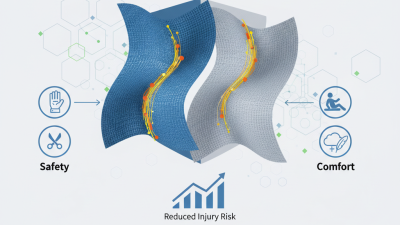

In sports, these bars enhance equipment performance. Lightweight bikes and strong fishing rods are just the beginning. Still, quality control is essential. Any flaws in production can lead to failures. Maintaining strict standards is crucial for safety.

Pultrusion carbon fiber bars are gaining attention in various industries. Their unique manufacturing process delivers a high-strength, lightweight material. Unlike traditional materials, carbon fiber bars resist corrosion and fatigue. This makes them popular in construction, automotive, and aerospace sectors.

The primary advantage of using pultrusion carbon fiber bars lies in their strength-to-weight ratio. They offer exceptional strength without the added bulk of metals. Additionally, they are easier to transport and install. The durability of these bars reduces the need for frequent replacements, translating to cost savings over time.

Tips for using pultrusion carbon fiber bars:

Consider the environment where the material will be used. Extreme temperatures can affect performance. Also, ensure proper bonding with other materials. This enhances the structural integrity of your project. Always follow safe handling practices. Awareness during installation can prevent damage and yield better results.

While pultrusion carbon fiber bars are highly beneficial, some drawbacks exist. They are more expensive than metals, and their repair can be complicated. Weighing the pros and cons is essential before making a decision. Understanding these aspects can lead to better choices in material selection, enhancing your project’s success.