-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

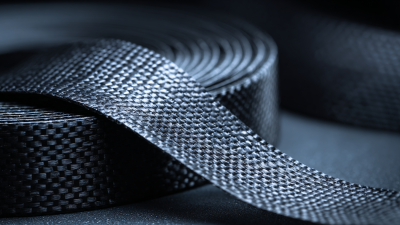

In the realm of lightweight engineering solutions, materials play a crucial role in determining the performance and efficiency of various applications. Among the myriad options available, the Rectangular Carbon Tube stands out as a superior choice, offering a unique combination of strength, durability, and minimal weight. This innovative material has been gaining traction in industries ranging from aerospace to automotive, where every gram saved translates to improved efficiency and performance.

One of the primary advantages of the Rectangular Carbon Tube is its exceptional structural integrity. By maximizing the strength-to-weight ratio, it allows engineers to design components that can withstand substantial loads without compromising on performance. Furthermore, the versatility of this material lends itself to a variety of fabrication processes, making it suitable for a broad spectrum of engineering projects.

In this article, we will explore the top five reasons why Rectangular Carbon Tubes are revolutionizing lightweight engineering solutions. From their superior mechanical properties to their aesthetic appeal, we will delve into how these tubes are not only meeting but exceeding the demands of modern engineering challenges. As innovations continue to emerge, understanding the benefits of Rectangular Carbon Tubes will be essential for professionals aiming to harness the full potential of lightweight design.

Rectangular carbon tubes have emerged as a premier choice in lightweight engineering, offering a myriad of advantages that are particularly beneficial in various applications. One of the primary benefits is their exceptional strength-to-weight ratio. The unique structure of these tubes allows for increased rigidity while minimizing overall weight, making them ideal for industries such as aerospace and automotive where every gram counts. Additionally, the uniform geometry of rectangular tubes facilitates efficient stress distribution, enhancing overall structural integrity under load.

Rectangular carbon tubes have emerged as a premier choice in lightweight engineering, offering a myriad of advantages that are particularly beneficial in various applications. One of the primary benefits is their exceptional strength-to-weight ratio. The unique structure of these tubes allows for increased rigidity while minimizing overall weight, making them ideal for industries such as aerospace and automotive where every gram counts. Additionally, the uniform geometry of rectangular tubes facilitates efficient stress distribution, enhancing overall structural integrity under load.

Another significant advantage of rectangular carbon tubes is their versatility. They can be easily customized in terms of dimensions and material composition, enabling engineers to tailor solutions to specific performance requirements. This adaptability not only streamlines design processes but also supports innovative applications in advanced technology sectors. Moreover, the resistance of carbon composites to environmental factors like corrosion ensures a longer lifespan, reducing maintenance costs and improving reliability in critical applications. These attributes solidify the status of rectangular carbon tubes as a cornerstone in the pursuit of lightweight yet robust engineering solutions.

When considering materials for lightweight engineering solutions, rectangular carbon tubes stand out in comparison to traditional materials such as steel and aluminum. Unlike steel, which offers strength but is significantly heavier, rectangular carbon tubes provide exceptional strength-to-weight ratios. This means that engineers can design structures that require less material without compromising on performance, making them ideal for applications ranging from aerospace to automotive engineering.

Furthermore, when contrasting rectangular carbon tubes with aluminum, another common lightweight option, the advantages become clear. Aluminum, while lightweight and versatile, has limitations in terms of rigidity and fatigue resistance. Rectangular carbon tubes, on the other hand, offer superior stiffness and durability, allowing for innovative designs that withstand greater stress and strain. This not only enhances the longevity of the components but also contributes to overall efficiency in engineering solutions, showcasing why rectangular carbon tubes are increasingly favored in modern design and manufacturing processes.

Rectangular carbon tubes embody a remarkable fusion of strength and design flexibility, making them an ideal choice for various lightweight engineering applications. Their unique geometry allows for the optimization of structural performance, enabling designers to create components that effectively distribute loads while maintaining minimal weight. This characteristic is particularly beneficial in industries such as aerospace and automotive, where every gram counts, and innovative design can lead to significant performance improvements.

The versatility of rectangular carbon tubes extends beyond mere load-bearing capabilities; they can be easily integrated into complex frameworks and structures. The ability to customize dimensions and thicknesses means that engineers can tailor these tubes to meet specific design criteria without compromising on strength or durability. Furthermore, the aesthetic potential of rectangular carbon tubes allows for a diverse range of applications, from sleek modern furniture to high-tech equipment housings, proving that functional engineering and visual appeal can coexist seamlessly in product design.

Rectangular carbon tubes have emerged as a cost-effective solution in the realm of lightweight engineering. Their unique structural properties allow for reduced material usage while maintaining strength and durability, making them an ideal choice for various applications in automotive, aerospace, and construction industries. The efficient use of carbon fiber in these tubes means that manufacturers can achieve significant weight savings without compromising performance, which leads to lowered fuel consumption and enhanced energy efficiency over time.

Investing in rectangular carbon tubes can also provide substantial long-term savings for engineers and designers. The manufacturing processes for these tubes have become increasingly advanced, resulting in lower production costs while retaining high-quality standards. Additionally, their versatility in design means less waste and better optimization of resources. By selecting rectangular carbon tubes, companies not only benefit from a lightweight solution but also reduce overall project expenses, paving the way for more economically viable engineering solutions in the competitive market.

This chart illustrates the cost per weight of different materials used in engineering solutions. Rectangular carbon tubes present a competitive cost per weight, though slightly higher than aluminum and steel, they provide unique advantages in terms of strength-to-weight ratio, making them an attractive choice for lightweight engineering applications.

The future of lightweight engineering is set to be transformed by the integration of rectangular carbon tubes. These advanced materials offer a unique combination of high strength-to-weight ratio, superior rigidity, and excellent fatigue resistance, making them ideal for various applications, from aerospace to automotive industries. As manufacturers increasingly prioritize efficiency and performance, rectangular carbon tubes stand out as an innovative solution that not only reduces overall weight but also enhances structural integrity. Emerging trends indicate that the adoption of rectangular carbon tubes will accelerate due to advancements in manufacturing techniques, such as automated processes and 3D printing. These developments allow for greater design flexibility, enabling engineers to create intricate configurations that were previously difficult to achieve. Furthermore, with growing environmental concerns, lightweight solutions such as these tubes contribute to improved fuel efficiency and lower emissions, aligning with sustainability goals. As research continues to push the boundaries of composite materials, rectangular carbon tubes are poised to redefine engineering standards, paving the way for a new era of lightweight design.