-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

When embarking on a project that requires the use of a Carbon Fiber Sheet, the right choice can significantly impact the outcome. Experts like Dr. Jane Thompson, a renowned materials engineer, have emphasized the importance of informed decisions. She once stated, "Selecting the right material is crucial for achieving optimal performance."

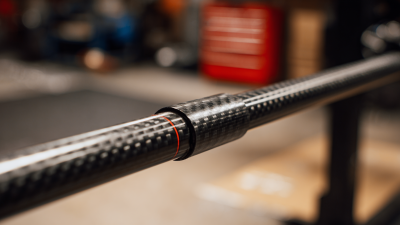

Carbon Fiber Sheets are known for their strength-to-weight ratio and versatility. However, not all sheets are created equal. Consider factors such as thickness, weave pattern, and resin type. These details may seem minor, but they greatly affect durability and application. Choosing the wrong specifications might lead to unforeseen challenges in your project.

It's essential to evaluate your needs carefully. A visually appealing design may be tempting, but functionality should be the priority. Reflecting on previous experiences can provide valuable insights. Ultimately, weighing pros and cons thoroughly will guide you toward the best Carbon Fiber Sheet for your specific application.

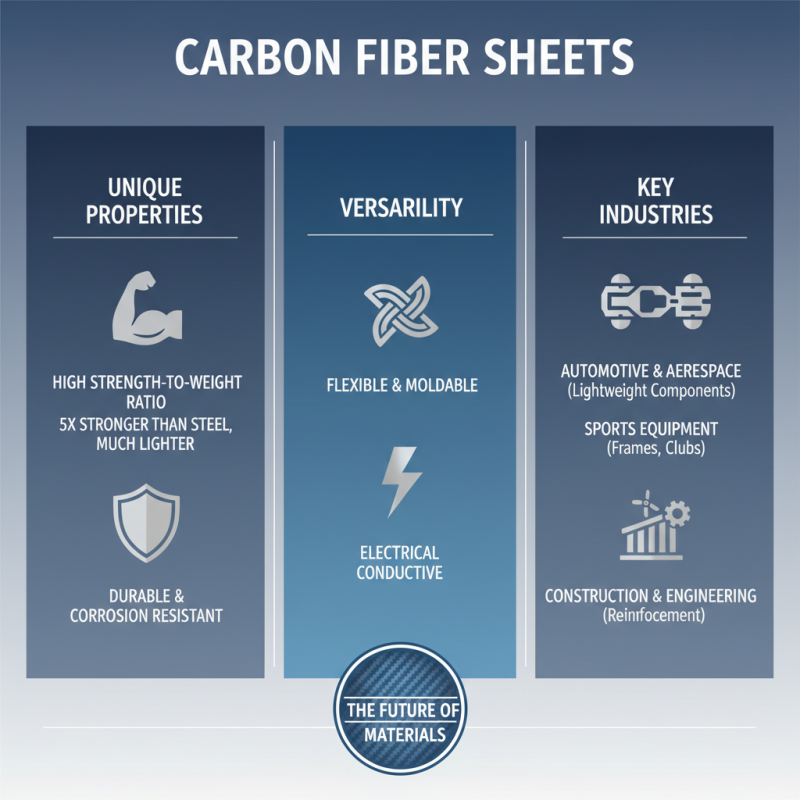

Carbon fiber sheets have gained popularity due to their unique properties and versatility. These sheets are known for their high strength-to-weight ratio. This means they are incredibly strong yet lightweight. For many industries, this is a game changer. According to industry reports, carbon fiber components can be five times stronger than steel while being significantly lighter.

The benefits extend beyond mere strength. Carbon fiber exhibits excellent resistance to corrosion and fatigue. Unlike metals, carbon fiber doesn’t rust, making it suitable for harsh environments. Additionally, it has low thermal expansion, which ensures dimensional stability across varied temperatures. A study suggests that carbon fiber can withstand temperatures up to 500 degrees Fahrenheit without degrading. However, the cost of carbon fiber remains a barrier for some projects. Prices can be ten times higher than traditional materials. This prompts designers to weigh immediate costs against long-term performance gains.

When selecting carbon fiber sheets, one must consider the intended application. Some projects may not require the high performance that carbon fiber offers. In such cases, it may not be a wise investment. Evaluating your project’s specific needs can help avoid unnecessary expenditure. Remember, each decision should align with both performance requirements and budget constraints.

When working on a project that requires a carbon fiber sheet, understanding your specific needs is crucial. Size, thickness, and weight all play vital roles in material selection. Most projects benefit from sheets that are at least 1 square foot in size, particularly if they require significant structural support. However, smaller applications may work well with dimensions closer to 6x6 inches.

Thickness is another essential factor. Carbon fiber sheets typically range from 0.5mm to 3mm or more. Thicker sheets provide greater strength but also add weight. According to the American Composites Manufacturers Association, a balanced approach is necessary. For lightweight projects like drones or automotive parts, a thinner sheet might suffice. Yet, for applications needing more rigidity, going thicker could be wise.

Weight considerations cannot be overlooked. Carbon fiber is celebrated for being lightweight. The density ranges from 1.5 g/cm³ to 2.0 g/cm³, making it ideal for performance-focused projects. However, lighter materials might sacrifice durability in some cases. Evaluate your needs carefully.

**Tips:** Always consider the manufacturing process and how the sheet will be cut. Precision matters. An incorrectly sized sheet may derail your project timeline. Seeking expert advice, especially when unsure, can clarify these needs. Don’t hesitate to revise your specifications as your understanding deepens.

| Project Type | Size (inches) | Thickness (mm) | Weight (lbs) | Finish Type |

|---|---|---|---|---|

| Aerospace Component | 12 x 12 | 1.5 | 2.5 | Glossy |

| Sports Equipment | 36 x 18 | 3 | 4.0 | Matte |

| Automotive Parts | 24 x 24 | 2 | 3.0 | Textured |

| Construction | 48 x 96 | 5 | 7.0 | Satin |

| Marine Applications | 24 x 72 | 3.5 | 5.0 | UV Resistant |

When choosing carbon fiber sheets, evaluating their quality is crucial. Start by examining the weave pattern. A tighter weave usually indicates better strength and durability. Look for inconsistencies; they can signal inferior quality. It's also important to check the thickness. Thicker sheets may offer more strength but can be heavier.

Tips: Consider your project's specific needs. If you need flexibility, opt for thinner sheets. For structural applications, a thicker sheet is better. Always request samples before making a bulk purchase. Testing a small section can save time and money later.

Another aspect to review is the resin type used. Epoxy resins tend to offer better performance compared to polyester. Trust your instincts when assessing the finish. A smooth, shiny surface often means quality craftsmanship. However, imperfections can serve as a reminder to choose wisely and reflect on your decisions.

When budgeting for a carbon fiber project, understanding costs is crucial. Carbon fiber sheets can range from $10 to $50 per square foot. The price varies based on thickness, weave type, and supplier. According to industry data, high-performance sheets typically cost more, reflecting enhanced durability and strength.

Beyond material costs, consider additional expenses. Manufacturing processes often require specialized tools and labor, which can add 20-30% to your budget. The layup process for carbon fiber requires skilled technicians. Training expenses can further escalate your initial project costs. Research indicates that projects with ample planning can mitigate unexpected expenses.

It's vital to anticipate maintenance and repair costs after project completion. Data shows that about 15% of budgets can be redirected for future repairs. These long-term costs shouldn't be overlooked. Understandable oversights happen, but thorough budgeting can significantly enhance project success.

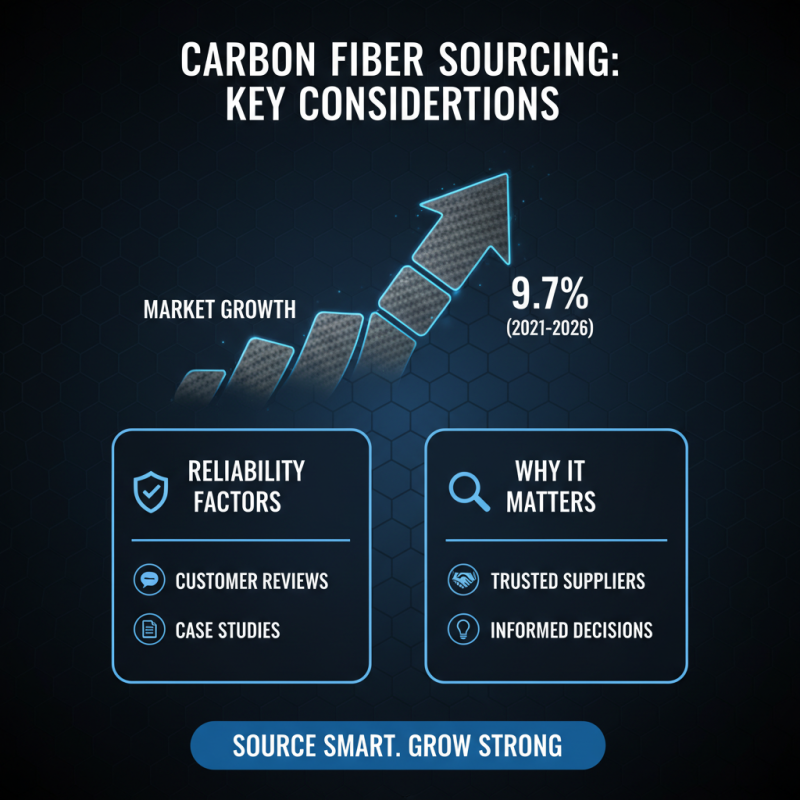

When sourcing carbon fiber sheets, it's crucial to consider the suppliers' reputation. Reliable suppliers often have customer reviews and case studies. Reports indicate that the carbon fiber market is expected to grow by 9.7% from 2021 to 2026. This makes understanding the sourcing landscape even more vital.

Look for suppliers that provide full transparency on their materials. Verify the product specifications and ensure they meet your project's requirements. One critical tip is to request samples before making a purchase. This helps assess the quality firsthand. It's also advisable to ask about production processes. Suppliers who openly share their methods often produce higher-quality products.

Don't forget to compare pricing among different suppliers. Some may have hidden fees or low-quality offerings at a reduced price. Balancing cost and quality is essential. Pay attention to delivery times and customer support, as these can impact your project timeline. A quick response from the supplier could indicate better service in the long run. Remember, choosing the right carbon fiber sheet involves careful consideration of various factors and suppliers.