-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

When embarking on a project that requires precision and strength, the choice of materials is crucial. Carbon fiber tubes are becoming increasingly popular due to their lightweight and robust properties. Renowned expert Dr. Emily Savinski, a material science specialist, once said, “Choosing the right carbon fiber tube can significantly impact your project’s success.” This highlights the importance of making informed decisions.

In the realm of engineering and design, the versatility of carbon fiber tubes stands out. They can be found in various applications, from aerospace to sporting goods. Selecting the right tube involves understanding specifications such as weight, diameter, and tensile strength. Each of these factors plays a vital role in the tube's performance.

However, navigating the options available in the market can lead to confusion. Not every carbon fiber tube is suited for every project. Some may focus solely on strength while neglecting flexibility. It's essential to reflect on the specific needs of your project. This careful consideration could mean the difference between failure and success.

Carbon fiber tubes are essential components in various applications. They are known for their lightweight nature and high strength. This makes them ideal for industries like aerospace, automotive, and sports equipment. Understanding their structure is crucial. Carbon fiber consists of thin filaments woven together, allowing for flexibility and durability.

Applications of carbon fiber tubes are diverse. In the automotive sector, they help reduce vehicle weight, improving fuel efficiency. In aerospace, these tubes enhance performance while maintaining structural integrity. However, users should note that not all carbon fiber tubes are equal. Variations in stiffness, length, and diameter can significantly affect performance.

Some projects may not require the highest quality tubes. Consider the specific needs of your project. For instance, a hobbyist may not need the same strength as a professional application. Reflecting on your requirements before purchase is vital. Choosing the right carbon fiber tube can save time and resources, but be prepared for trial and error in the selection process.

When selecting carbon fiber tubes for your projects, several key factors come into play. First, you need to consider the tube's diameter. The diameter affects the strength and weight. A thicker tube can bear more load but may add unwanted weight. Balance is critical. Don't rush; evaluate how the diameter fits your project's specific needs.

Next, look at the tube's wall thickness. Thicker walls usually mean more strength and stiffness. However, they also increase weight. It’s a trade-off that requires careful thought. Try to visualize how much strength you actually need. In some cases, it may be better to opt for a lighter option.

Finally, consider the tube's weave pattern. Different patterns offer varying flexibility and strength. A simple weave might suffice for standard applications, while a more complex pattern may be necessary for high-stress environments. Experiment with different options to see what works best. A good fit will enhance performance, but poor choices can lead to project failures. These choices matter greatly.

When selecting carbon fiber tubes for various projects, evaluating strength, weight, and flexibility is crucial. Carbon fiber boasts high tensile strength, often exceeding 600 MPa, making it ideal for applications requiring durability. Its remarkable strength-to-weight ratio allows structures to achieve significant robustness without adding excessive weight. Many engineers appreciate this aspect, especially in aerospace and automotive industries.

Weight savings are essential in many designs. Compared to aluminum, carbon fiber can be up to 30% lighter while maintaining similar strength. The reduced weight translates to better fuel efficiency and performance in vehicles. However, some may overlook how stiffness interacts with flexibility. Flexible designs can sometimes outperform rigid ones in dynamic applications. Not every project requires maximum stiffness; alternating between stiffness and flexibility could enhance functionality.

Choosing the correct modulus of elasticity is vital. Carbon fiber tubes can vary widely, from around 70 GPa to over 300 GPa. This variation affects how the tubes respond under load. A tube with low elasticity may bend under pressure, while another with high elasticity could shatter. Engineers must research their specific needs, reflecting on whether strength or flexibility is more critical for the given application. Balancing these factors takes careful consideration and foresight.

This chart illustrates key properties of carbon fiber tubes such as tensile strength, flexural strength, weight, and flexibility, which are crucial considerations when selecting carbon fiber tubes for various projects.

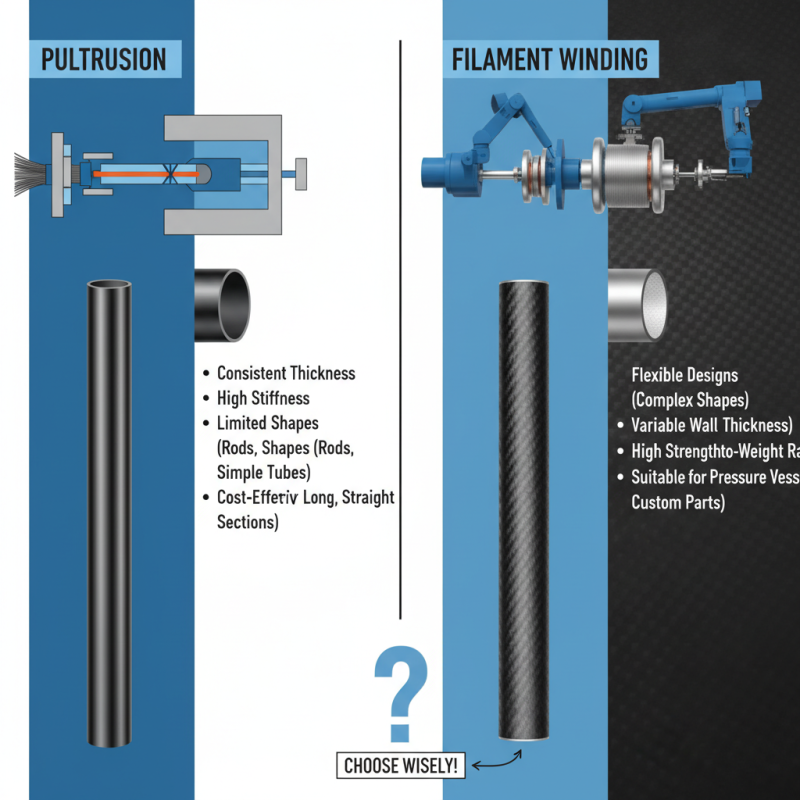

When selecting carbon fiber tubes for your projects, understanding the manufacturing processes is crucial. Various methods yield different qualities and characteristics. For example, pultrusion provides consistent thickness but may limit shape options. On the other hand, filament winding offers flexibility in design but can introduce variability in wall thickness. Recognizing these differences can guide your material choice effectively.

Consider the type of resin used in the manufacturing process. Epoxy resins offer better adhesion and durability but can be pricier. Vinyl ester resins provide a solid balance between strength and cost. Knowing what works best for your application is essential.

When choosing carbon fiber tubes, remember to assess their stiffness and weight. A lighter tube may be appealing, but it could compromise strength. Reflect on your project requirements. Sometimes, a heavier tube may provide the necessary durability. Balancing these factors ensures you get the right tube without unnecessary trade-offs.

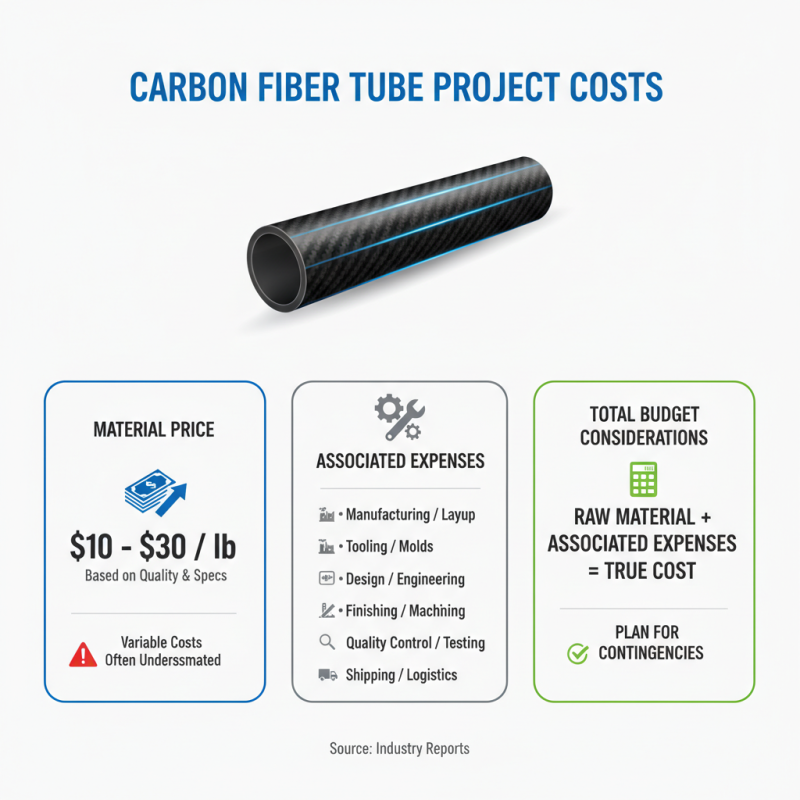

When planning a project involving carbon fiber tubes, cost is a critical factor. According to industry reports, the price of carbon fiber materials can range from $10 to $30 per pound, depending on quality and specifications. Many buyers report underestimating their budgets due to these variable costs. It’s important to consider not just the raw material but also the associated expenses.

Installation and manufacturing costs can further inflate your budget. Traditional methods of shaping carbon fiber may require expensive tools and skilled labor. Reports indicate that projects often need additional funds for prototyping and testing phases. This can lead to unexpected financial strain.

Moreover, the longevity and performance benefits of carbon fiber can seem attractive. Yet, these often come with upfront costs. A project's success hinges on balancing initial expenses with long-term savings. Remember, a thorough cost assessment prevents future regrets and helps refine your project scope. Investing in comprehensive research today can save money later.