-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the ever-evolving world of materials science, carbon fiber sheets have emerged as a game-changer, revolutionizing various industries with their unparalleled strength and lightweight properties. According to Dr. Emily Novak, a renowned expert in advanced composite materials, "The versatility of carbon fiber sheets is unmatched; they offer solutions that were previously deemed impossible." This quote underlines the significance of this material in modern applications, ranging from aerospace to automotive engineering, and even in sporting goods.

As we delve into the top 10 applications of carbon fiber sheets, it's essential to recognize how this innovative material enhances performance and efficiency across different sectors. By harnessing the unique characteristics of carbon fibers, industries are able to develop products that not only perform better but also contribute to sustainability by reducing weight and energy consumption. The following sections will explore these transformative applications, illustrating why understanding carbon fiber sheets is crucial for professionals and enthusiasts alike in today's technology-driven landscape.

Carbon fiber sheets have gained immense popularity across various industries due to their exceptional strength-to-weight ratio and versatility. One of the most significant applications is in the automotive sector, where manufacturers utilize carbon fiber to enhance performance and fuel efficiency. By incorporating these lightweight materials into vehicles, manufacturers can reduce overall weight without compromising safety or durability, leading to improved handling and acceleration.

Another prominent application of carbon fiber sheets is in the aerospace industry. Aircraft components made from carbon fiber offer enhanced structural integrity while significantly reducing weight, which is crucial for cost-effective fuel consumption and improved flight efficiency. Additionally, carbon fiber's resistance to corrosion makes it an ideal choice for both commercial and military aircraft, ensuring longevity and reduced maintenance costs.

In the sporting goods sector, carbon fiber is widely used in high-performance equipment such as bicycles, tennis rackets, and fishing rods. The material's lightweight characteristics facilitate superior maneuverability and increased speed, catering to the demands of professional athletes. Moreover, its stiffness contributes to better energy transfer during performance, making carbon fiber an invaluable asset in competitive sports.

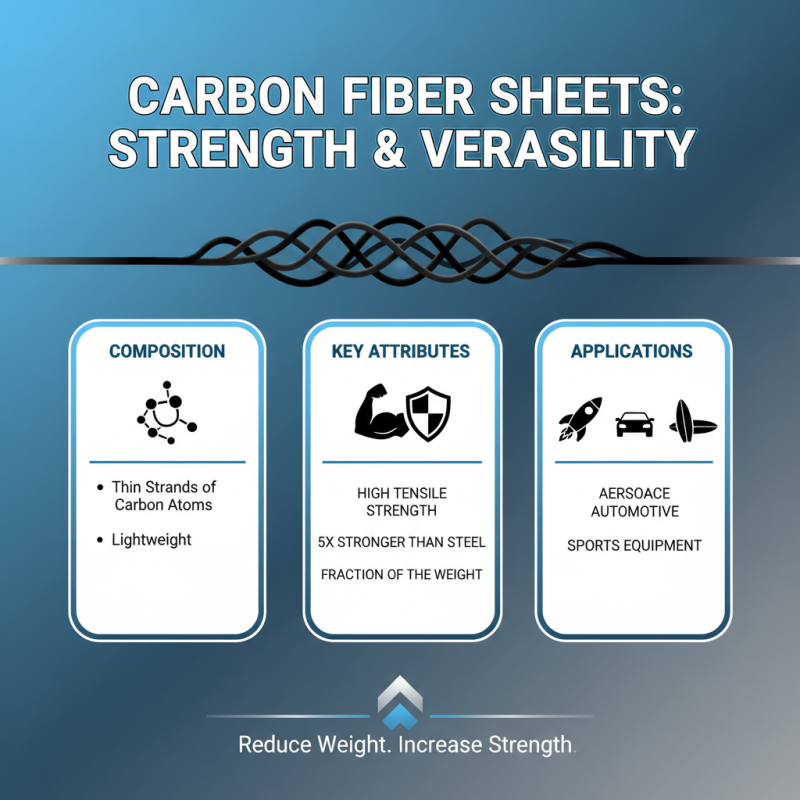

Carbon fiber sheets have gained significant popularity due to their unique combination of high strength-to-weight ratio and versatility. Carbon fiber, composed of thin strands of carbon atoms, exhibits remarkable properties that make it an ideal material for various applications. One of the key attributes of carbon fiber sheets is their exceptional tensile strength, which can be up to five times greater than that of steel while being only a fraction of the weight. This property makes them highly suitable for industries such as aerospace, automotive, and sports equipment manufacturing, where reducing weight while maintaining strength is critical.

In addition to their strength, carbon fiber sheets also demonstrate excellent resistance to corrosion and thermal expansion, allowing for longevity in diverse environments. According to market research reports, the global carbon fiber market is expected to reach USD 4.23 billion by 2024, growing at a compound annual growth rate (CAGR) of 9.8% from 2019. This growth stems from the expanding applications of carbon fiber in sectors beyond traditional manufacturing, such as in wind energy, where lightweight components can enhance efficiency and performance. With ongoing innovations and advancements in carbon fiber technology, we can expect to see even broader adoption of these materials in various fields, highlighting their indispensable role in modern engineering and design.

The aerospace industry has been at the forefront of innovation, constantly seeking materials that can enhance aircraft performance while reducing weight. Carbon fiber sheets have emerged as a game-changer in this domain. Recognized for their exceptional strength-to-weight ratio, carbon fiber composites allow aircraft manufacturers to design lighter, faster, and more fuel-efficient planes. This shift not only boosts performance but also leads to significant cost savings in fuel consumption over the aircraft's lifecycle.

When considering carbon fiber for aerospace applications, it's vital to prioritize quality and compatibility with existing structural designs. Tips for incorporating carbon fiber sheets effectively include performing a thorough weight analysis to determine the optimal use of the material and ensuring that all components adhere to strict aerospace standards. Additionally, expert guidance from material engineers can aid in selecting the right type of carbon fiber, considering factors such as environmental resistance and flexibility tailored to specific aircraft needs.

Another crucial aspect is maintenance. Carbon fiber, while durable, requires proper care to sustain its performance characteristics. Regular inspections for signs of wear or damage can prevent small issues from escalating, ensuring the longevity of aircraft components. By embracing carbon fiber technology and adhering to recommended maintenance protocols, the aerospace industry can leverage its full potential, paving the way for the next generation of aircraft design.

| Application | Description | Benefits | Weight Reduction (%) |

|---|---|---|---|

| Aircraft Structure | Used for fuselage and wing structures. | Increased strength and durability. | 20-40% |

| Propellers | Manufactured for enhanced aerodynamic performance. | Improves fuel efficiency and performance. | 15-25% |

| Interior Components | Used in seats, cabinetry, and panels. | Lightweight and high-end finish. | 10-20% |

| Landing Gear | Components designed for strength and resilience. | Reduction in weight without sacrificing safety. | 30-50% |

| Wing Flaps | Enhanced lift during take-off and landing. | Improved control and aerodynamics. | 20-35% |

| Tail Section | Used in rudders and elevators. | Enhanced structural integrity. | 25-40% |

| Fuel Tanks | Lightweight and durable fuel storage solutions. | Increased range and reduced operational costs. | 15-20% |

| Adhesives and Composites | Used in bonding and structural applications. | Superior bonding strength. | Varies by application |

| Control Surfaces | Used in ailerons and spoilers. | Improved responsiveness and performance. | 20-30% |

The automotive industry has consistently sought innovative solutions to enhance fuel efficiency, and carbon fiber sheets have emerged as a game-changer in this arena. A report by the Lightweight Materials Market indicates that vehicles made with carbon fiber composites can reduce weight by up to 50% compared to traditional materials like steel. This reduction in mass not only contributes to lower fuel consumption but also improves vehicle performance and agility, allowing manufacturers to meet increasingly strict emissions regulations.

As electric and hybrid vehicles gain traction, the use of carbon fiber in automotive design has become crucial. In fact, recent studies project that the demand for carbon fiber in the automotive sector will increase by 25% by 2026, driven by the need for lightweight structures that enable longer battery life and enhanced driving range. For instance, integrating carbon fiber sheets into the chassis and body panels can lead to significant reductions in energy expenditure. This shift not only propels the automotive sector towards sustainability but also aligns with consumer demands for more fuel-efficient vehicles in an era of heightened environmental awareness.

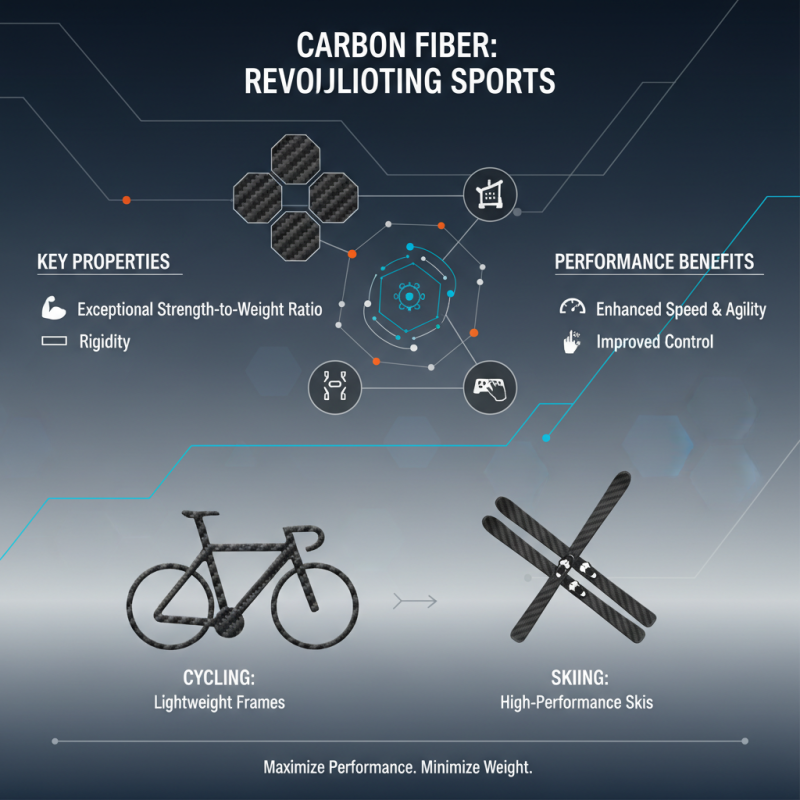

Carbon fiber has revolutionized the sporting goods industry by providing athletes with equipment that maximizes performance while minimizing weight. The unique properties of carbon fiber—its exceptional strength-to-weight ratio and rigidity—enable manufacturers to design products that enhance speed, agility, and control. For example, in sports like cycling and skiing, carbon fiber sheets are utilized to construct lightweight frames and skis that enable athletes to achieve greater speeds and improve their overall handling.

Beyond the traditional applications, carbon fiber is making waves in team sports as well. It is increasingly used in the design of protective gear, such as helmets and pads, offering superior impact resistance without compromising mobility. Additionally, equipment like tennis rackets and golf clubs benefit greatly from carbon fiber's ability to absorb vibrations, allowing for a smoother, more powerful strike. With ongoing advancements in carbon fiber technology, athletes are gaining access to increasingly sophisticated gear that directly translates into enhanced performance on the field and court.

Carbon fiber sheets are renowned for their unique properties, including high strength-to-weight ratio, durability, and resistance to corrosion. These characteristics have made them essential in various industries. In the aerospace sector, carbon fiber sheets enhance aircraft performance by reducing weight while maintaining structural integrity. The automotive industry benefits from these lightweight materials as they contribute to greater fuel efficiency and improved speed.

Moreover, carbon fiber sheets are increasingly utilized in sporting goods, providing athletes with equipment that boosts performance without adding excess weight. In the medical field, advancements in biocompatible carbon fiber solutions are paving the way for innovative medical devices. Overall, the applications of carbon fiber sheets are vast and continue to evolve, showcasing the material's versatility and significance across multiple domains.