-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

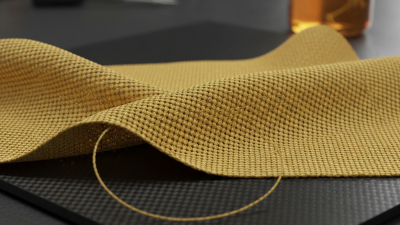

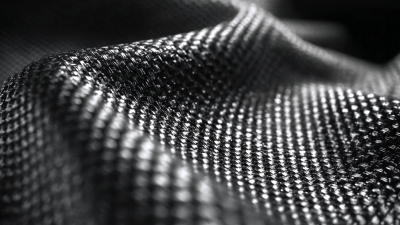

As industries continue to innovate and evolve, the adoption of advanced materials such as Carbon Fibre Mesh is taking center stage. By 2025, the market for carbon fibre composites is projected to exceed $6 billion, highlighting the extensive potential and versatility of this lightweight yet strong material across various sectors. According to the latest report from the International Composite Materials Association, the demand for carbon fibre solutions is anticipated to grow by 17% annually, driven by increasing applications in aerospace, automotive, and sports equipment industries.

Dr. Emily Carson, a leading expert in composite materials, emphasizes the significance of Carbon Fibre Mesh in modern manufacturing: “The unique properties of Carbon Fibre Mesh, including its high strength-to-weight ratio and corrosion resistance, make it an ideal choice for high-performance applications.” As we explore the top ten applications of Carbon Fibre Mesh in 2025, it becomes evident that this innovative material is set to revolutionize how products are designed and developed, improving efficiency and sustainability in various industrial processes. By understanding these applications, industries can better harness the advantages of Carbon Fibre Mesh, propelling them toward a more advanced, sustainable future.

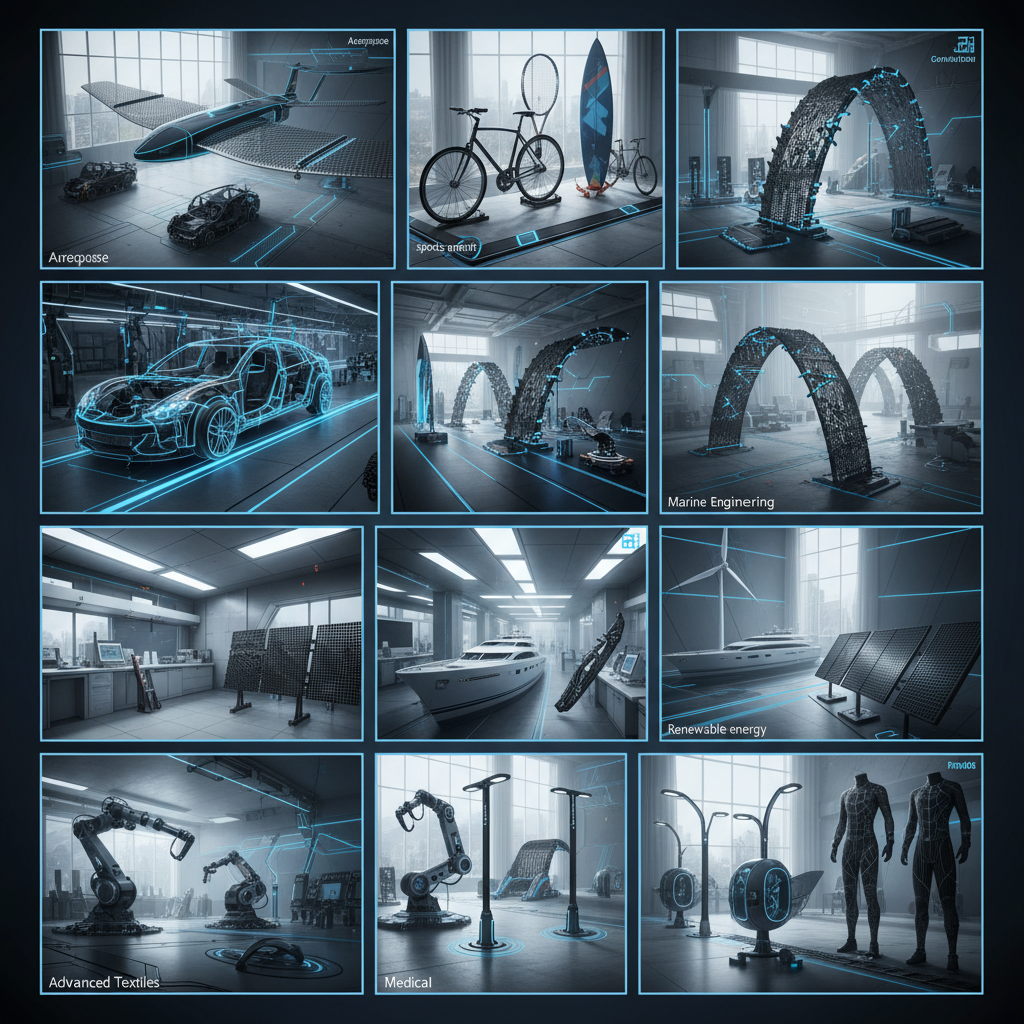

Carbon fibre mesh technology is revolutionizing aerospace engineering by significantly improving the weight-to-strength ratio of aircraft structures. The lightweight nature of carbon fibre mesh allows for the design of components that do not compromise on strength while reducing overall mass. This is crucial, as every kilogram saved translates into fuel efficiency and reduced emissions, aligning with the industry's goal for more sustainable aerospace solutions.

Additionally, the flexibility and robustness of carbon fibre mesh enable the creation of intricate shapes that can enhance aerodynamics. By integrating this advanced material into wings, fuselage sections, and other critical components, engineers can optimize performance while maintaining safety standards. Moreover, the corrosion resistance of carbon fibre increases the lifespan of aircraft parts, contributing to lower maintenance costs and improved operational efficiency. As aerospace continues to push the boundaries of innovation, the application of carbon fibre mesh stands out as a key player in achieving next-generation aircraft designs.

| Application Area | Primary Benefit | Weight Reduction (%) | Strength Enhancement (%) | Typical Use Case |

|---|---|---|---|---|

| Aerospace Structures | Improved fuel efficiency | 20-30 | 10-15 | Airframes, wings |

| Satellite Components | Increased payload capacity | 15-25 | 12-18 | Structural elements |

| Helicopter Blades | Enhanced lift capabilities | 20-35 | 15-20 | Rotors |

| Drone Frames | Increased flight time | 25-40 | 5-10 | Consumer, commercial drones |

| Automotive Parts | Lower emissions | 10-20 | 8-12 | Body panels, chassis |

| Wind Turbine Blades | Higher efficiency | 15-30 | 10-18 | Large-scale turbines |

| Sporting Goods | Enhanced performance | 20-45 | 5-10 | Bicycles, golf clubs |

| Medical Devices | Improved patient outcomes | 5-15 | 7-10 | Prosthetics, surgical instruments |

| Construction Materials | More durable builds | 10-20 | 10-15 | Reinforcement, insulation |

Carbon fibre mesh has emerged as a game-changer in automotive manufacturing, driving significant advancements in fuel efficiency and performance optimization. According to a recent report by the International Council on Clean Transportation, vehicles that utilize carbon fibre components can reduce overall weight by up to 50% compared to traditional materials. This weight reduction directly correlates with enhanced fuel efficiency, as lighter vehicles require less energy to operate, resulting in a decrease in CO2 emissions by approximately 30%.

Furthermore, carbon fibre mesh is revolutionizing vehicle design by allowing for more complex shapes and structures that improve aerodynamic performance. A study conducted by the Automotive Research Association revealed that incorporating carbon fibre mesh can improve a vehicle's aerodynamics by up to 15%, leading to better handling and stability at high speeds. As automotive manufacturers increasingly adopt this innovative material, the potential for increased performance combined with reduced environmental impact positions carbon fibre mesh as a crucial element in the evolution of the modern automotive industry.

This chart illustrates the anticipated improvements in fuel efficiency and performance optimization achieved through the utilization of carbon fibre mesh in various automotive applications by 2025. The data represents an estimated percentage increase in effectiveness across different automotive components.

Carbon fibre mesh has emerged as a transformative material in the field of civil engineering, significantly enhancing the durability and integrity of structures. According to a report by the American Composites Manufacturers Association, the use of carbon fibre composites in construction can reduce material costs by 30% while simultaneously increasing strength by up to 200%. This remarkable strength-to-weight ratio enables civil engineers to design lighter, more resilient structures, minimizing the risk of fatigue and failure over time, especially in seismic-prone regions.

Moreover, the application of carbon fibre mesh plays a crucial role in rehabilitation projects. Research published in the Journal of Infrastructure Systems indicates that integrating carbon fibre mesh can increase the lifespan of existing concrete structures by 50% or more. This makes it an ideal solution for retrofitting aging infrastructure, such as bridges and buildings, allowing for extended service without the need for complete reconstruction. As urban areas continue to grow and materials age, the adoption of carbon fibre mesh in civil engineering will be pivotal for maintaining the safety and sustainability of infrastructure.

The application of carbon fibre mesh in sports equipment is rapidly evolving, driven by a relentless pursuit of performance and safety enhancements. Athletes and manufacturers alike are embracing carbon fibre mesh for its lightweight yet robust properties. In gear such as helmets, protective padding, and even composite racquets, the integration of this material significantly reduces weight without compromising structural integrity. This advancement allows athletes to achieve greater speeds and maneuverability while minimizing the risk of injury.

Furthermore, innovations in carbon fibre mesh technology are paving the way for smart sports equipment that can monitor performance metrics in real time. For instance, smart helmets equipped with carbon fibre mesh can feature sensors that track impact force, providing instant feedback to players and coaches. This real-time data not only aids in optimizing performance but also plays a crucial role in injury prevention strategies.

As these trends continue to shape the industry, carbon fibre mesh is set to redefine the boundaries of athletic performance, ensuring both safety and enhanced capabilities on the field.

Carbon fibre mesh has rapidly emerged as a pivotal material in the medical device industry, primarily due to its lightweight and biocompatible characteristics.

The integration of carbon fibre mesh in devices such as prosthetics and surgical implants has revolutionized performance standards, minimizing the physical burden on patients while ensuring structural integrity.

Manufacturers are increasingly leveraging these properties to produce custom-fit solutions that enhance patient comfort and mobility, setting new benchmarks for medical interventions.

Moreover, the biocompatibility of carbon fibre mesh is critical in reducing the likelihood of adverse reactions in the body.

Its ability to integrate seamlessly with biological tissues allows for extended use in long-term implants without causing inflammation or rejection.

This innovative approach is sparking a wave of research focused on optimizing carbon fibre mesh for specific medical applications, paving the way for advanced treatments in orthopedics, cardiovascular devices, and even soft tissue repairs.

As the technology continues to advance, the future of medical devices looks increasingly promising with the adoption of carbon fibre mesh at its core.