-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

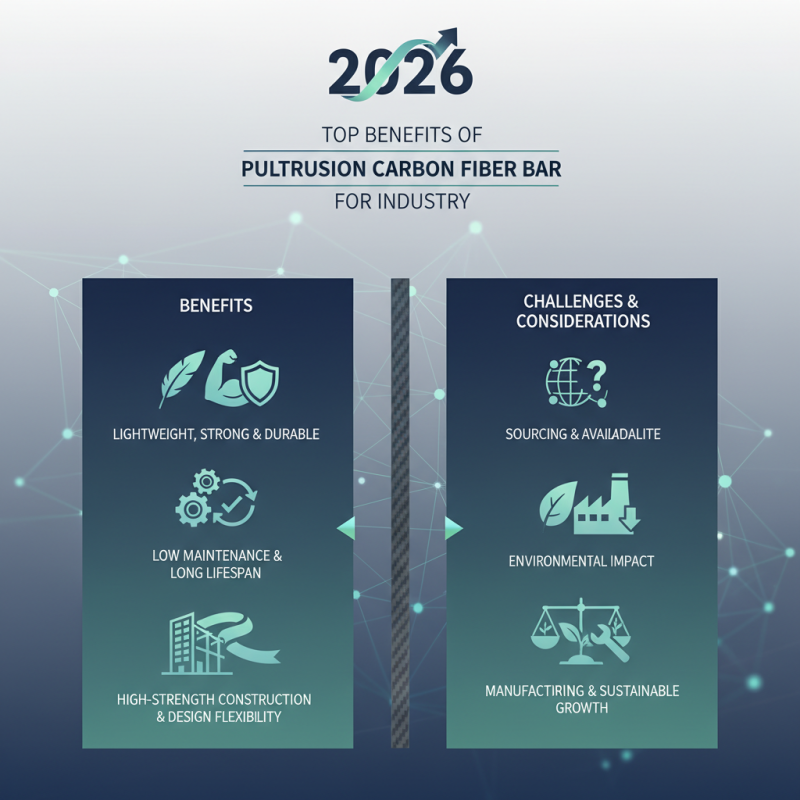

The Pultrusion Carbon Fiber Bar is revolutionizing various industries. Its unique properties enable significant advantages over traditional materials. Lightweight yet incredibly strong, it offers durability and resistance to chemicals. This means lower maintenance costs and longer life spans for applications.

In construction, the Pultrusion Carbon Fiber Bar lends itself to high-strength reinforcements. Designers appreciate its flexibility in creative applications. Yet, some might find it challenging to source this material consistently. Availability in different specifications can be an issue.

Moreover, its environmental impact must be considered. While it reduces energy consumption, the manufacturing process has room for improvement. As industries adopt Pultrusion Carbon Fiber Bars, ongoing evaluation is crucial. Balancing benefits against production challenges ensures sustainable growth.

The pultrusion process is a continuous manufacturing method. It combines fibers, typically carbon, with resin to create strong composite materials. This technique offers efficient production and high strength-to-weight ratios. It involves pulling raw materials through a heated die, shaping them into specific profiles.

In industries like construction and automotive, pultruded carbon fiber bars serve vital roles. These bars provide excellent tensile strength, making them suitable for structural applications. However, challenges exist. Quality control during the process can be tricky. Variability in resin curing times can affect product consistency. Manufacturers must hone their techniques to address these issues and ensure optimal performance.

The significance of pultrusion in manufacturing lies in its ability to create lightweight yet durable components. The demand for such materials continues to grow. As industries look for efficiency and sustainability, exploring new applications is essential. Carefully evaluating the limitations of pultrusion can help in fine-tuning its use in various sectors.

This chart illustrates the top five benefits of pultrusion carbon fiber bars for various industries in 2026. The ratings signify their relevance and importance, with "Lightweight" being rated the highest.

Carbon fiber bars have gained significant traction in various industries. Their unique properties make them ideal for many applications. Lightweight yet robust, they are significantly stronger than traditional materials. Their strength-to-weight ratio is exceptional, which leads to increased efficiency in manufacturing and construction.

These bars are also resistant to corrosion. This characteristic enhances their durability, making them suitable for harsh environments. In addition, they maintain their structural integrity over time, unlike metals that can weaken. Carbon fiber bars can endure extreme temperatures, aiding performance in diverse environments.

Tips: When choosing carbon fiber bars, consider the application. Think about the weight limits and the environment. Regular inspections are crucial. Ensure there are no signs of wear or damage. While these materials are strong, they can fail if not monitored.

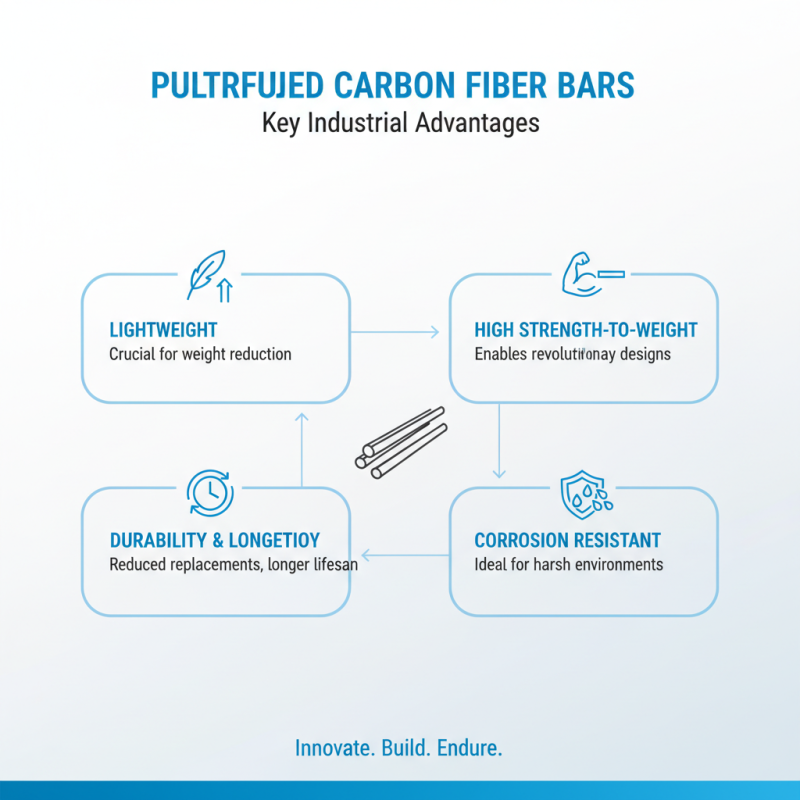

Pultrusion carbon fiber bars have become vital in various industries. Their lightweight nature makes them a preferred choice where weight reduction is crucial. These bars offer high strength-to-weight ratios, allowing designs that were once impossible. They resist corrosion, making them ideal for outdoor and harsh environments. This resilience can lead to longer-lasting products and fewer replacements.

**Tips:** When considering pultruded carbon fiber, assess project requirements. Calculate load-bearing needs accurately. Sometimes, lighter is not always better.

Another major advantage is their versatility. Pultrusion allows for tailored shapes and sizes to fit specific applications. This customization can enhance performance in unique spaces. However, manufacturers must communication closely with designers. Misunderstandings often lead to unexpected costs or delays.

**Tips:** Collaborate early in the design process. Share detailed specifications to avoid mistakes. Flexibility in planning can mitigate unforeseen issues.

Pultrusion carbon fiber bars can reduce maintenance costs due to their durability. They withstand harsh chemicals and extreme temperatures. However, industries should weigh initial investment against long-term savings. If budgets are tight, this may pose a challenge. Balancing quality with cost-effectiveness requires careful thought.

Pultrusion carbon fiber bars present a compelling alternative to traditional materials like steel and aluminum. These bars are significantly lighter. For instance, carbon fiber can be up to five times lighter than steel. This weight advantage allows for easier handling and reduced transportation costs. Additionally, pultruded carbon fiber offers better corrosion resistance compared to metals. It maintains its strength in harsh environments, such as those exposed to moisture or chemicals.

However, the cost of carbon fiber can be a barrier. It typically requires a higher upfront investment compared to traditional materials. In some cases, the long-term savings in maintenance and longevity might not justify this initial expense for certain industries. Moreover, the manufacturing process still needs refinement to improve efficiency. Here, traditional methods may have the upper hand, as they can produce bulk quantities rapidly.

Despite these challenges, the strength-to-weight ratio of pultrusion carbon fiber bars is impressive. They deliver superior performance in applications demanding rigidity and structural integrity. Industries such as aerospace and automotive are already recognizing this potential. However, widespread adoption depends on addressing cost and manufacturing speed. The industry must evolve to fully harness the benefits of this innovative material.

Pultrusion technology is evolving rapidly. Industry experts predict significant advancements in carbon fiber pultrusion by 2026. According to a recent report by Research and Markets, the market for pultruded composites is expected to grow by 5.2% annually. This growth reflects the rising demand for lightweight, durable materials in various sectors, including automotive and aerospace.

Future innovations focus on enhancing the efficiency of pultrusion processes. Automated systems may soon reduce production times by up to 30%. The integration of artificial intelligence could improve quality control. Yet, there's a risk of neglecting manual oversight. Balancing automation with human expertise is crucial. A failure to do so could lead to quality compromises.

Sustainability is another crucial trend. Eco-friendly resins are gaining traction, responding to both industry demand and environmental concerns. Reports indicate that nearly 40% of manufacturers are exploring renewable material options. However, questions remain about the long-term performance of these alternatives. Maintaining strength while pursuing greener options is a challenge that needs more exploration.