-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

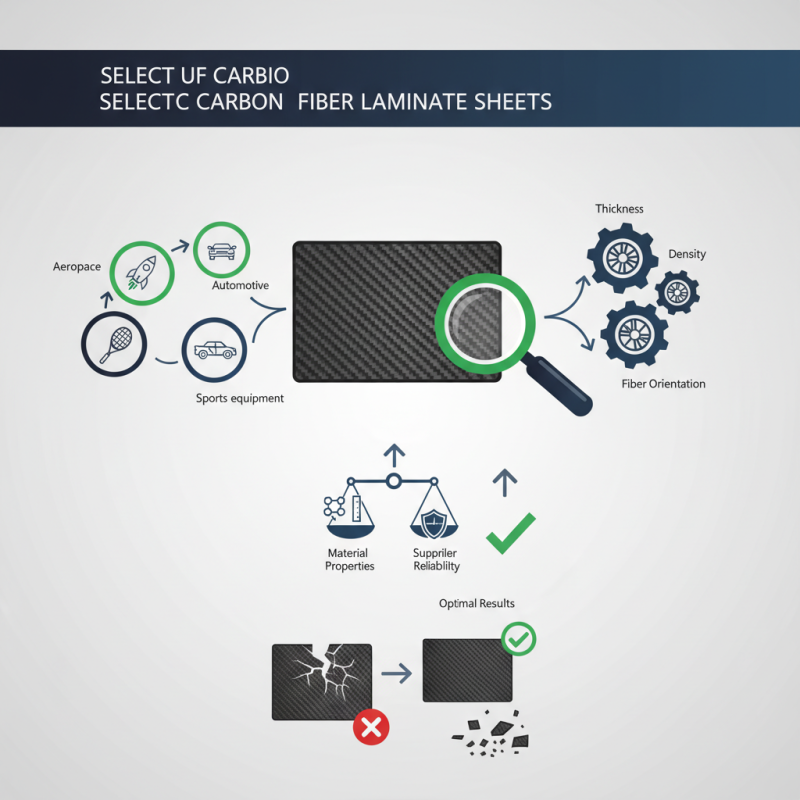

Choosing the right Carbon Fiber Laminate Sheet is crucial for various applications. Industries such as aerospace, automotive, and sports equipment rely on these materials. According to a recent market report, the carbon fiber composite market is expected to grow at a CAGR of 10.78% from 2023 to 2028. This growth emphasizes the importance of understanding how to select the correct laminate sheet.

Expert John Smith, a leading specialist in composite materials, once stated, “Selecting the right carbon fiber laminate can significantly impact performance and durability.” His insights highlight the necessity of making informed choices. Challenges can arise from differing laminate thickness, density, and fiber orientation. Not every sheet suits every project.

In this rapidly evolving industry, making a misguided choice can lead to costly failures. It is essential to evaluate specific material properties and supplier reliability. Many users overlook these factors, which can compromise the intended use of Carbon Fiber Laminate Sheets. Paying attention to these details is vital in achieving optimal results in your applications.

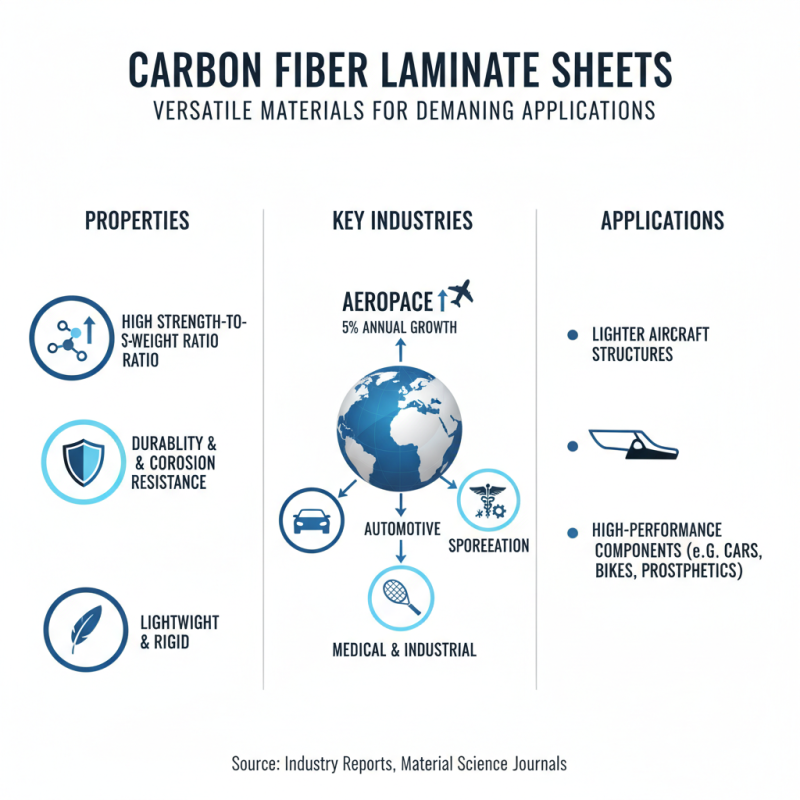

Carbon fiber laminate sheets are versatile materials widely used across various industries. Their unique properties make them suitable for demanding applications. For instance, in aerospace, carbon fiber's high strength-to-weight ratio allows for lighter aircraft designs. Reports indicate that the aerospace sector alone is projected to grow by 5% annually, driven by advancements in material technology.

In automotive manufacturing, carbon fiber laminates enhance vehicle performance. These materials reduce weight, improving fuel efficiency. A study highlighted that a mere 100 kg reduction could lead to a 3-5% increase in fuel efficiency. However, choosing the right laminate sheet requires careful consideration. Factors like thickness, weave pattern, and curing process play a crucial role in performance.

Despite their advantages, carbon fiber materials pose challenges. The production process can be costly and time-consuming. Sustainability remains a concern, as recycling options are limited. This can lead to environmental issues that need addressing. Users must reflect on the long-term implications of their choices. Understanding these aspects is essential for making informed decisions in applications.

When selecting carbon fiber laminate sheets, a few key factors stand out. Consider the thickness of the sheet. Thicker sheets offer greater strength but can be heavier. Lightweight options may lack durability in high-stress applications, so balance is crucial. Pay attention to the weave pattern as well. Varsity-grade sheets often feature a twill or plain weave, affecting aesthetics and performance. Weaves can influence strength and flexibility, so choose wisely.

The resin type used in the laminate is another essential aspect. Epoxy resins are popular due to their superior adhesion and weather resistance. However, they can be pricier and may not be necessary for every project. On the other hand, polyester resins are cost-effective but often less durable. Assess your budget and requirements carefully.

Lastly, ensure the sheets meet relevant specifications and standards. Not all carbon fiber sheets are created equal. Some may not hold up under certain conditions, leading to risky failures. Conducting thorough research and comparisons will pay off in the long run. With so many variables, it's easy to overlook something important. A second look can help catch issues before they become problems.

When evaluating carbon fiber laminate sheets, quality and durability are crucial factors. High-quality carbon fiber sheets should ideally have a tensile strength exceeding 3,500 MPa and a weight-to-strength ratio that substantially outperforms aluminum. A report from CompositesWorld indicates that well-manufactured laminates can provide excellent fatigue resistance and lower thermal expansion.

Consider the thickness of the carbon fiber sheets. Thicker sheets often increase durability, but they can also add weight. It’s vital to strike a balance between strength, weight, and application needs. Testing the laminate's resistance to impact is also a practical approach. A study published in the Journal of Reinforced Plastics and Composites shows that quality laminates can withstand considerable forces without delaminating.

Tip: Verify certifications of carbon fiber products. Look for compliance with industry standards. This ensures that the materials you select meet safety and performance expectations.

Another factor to keep in mind is the manufacturing process. Not all carbon fibers are created equal. Continuous fiber is generally superior to chopped fiber for structural applications. Always check the fabrication methods used in your chosen sheet. Discrepancies in production can lead to weak spots that may not be visible at first glance.

Tip: Inspect samples before purchasing. Pay attention to surface defects or variations in texture. These can indicate potential weaknesses in the laminate's structure.

When choosing carbon fiber laminate sheets, evaluating costs and benefits across brands is crucial. Prices vary significantly among options. Some sheets may appear cheaper at first glance, but hidden costs can arise in performance and durability. It's essential to understand that a lower price may lead to more expenses down the line.

Take the weight-to-strength ratio into consideration. Some brands offer sheets that may be lighter or stronger while remaining competitively priced. It’s not always obvious from the product description. This can lead to disappointing outcomes if the sheet doesn't meet your project needs.

Don’t overlook the sources of these materials. Local suppliers might charge more, but they can provide essential support. Reliability and service can make a significant difference. Also, check reviews. Sometimes, they offer insights that aren't visible in specifications. Evaluate the long-term value of your choice, not just the immediate cost.

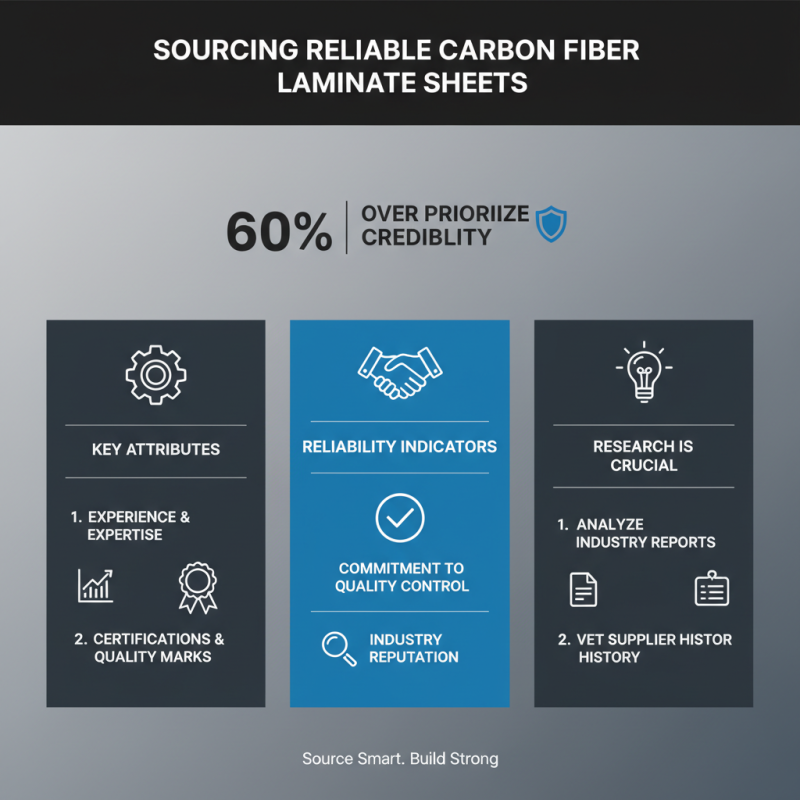

When sourcing reliable suppliers for carbon fiber laminate sheets, research is crucial. Industry reports suggest that over 60% of buyers prioritize supplier credibility. A supplier's experience and expertise reflect their reliability. Certifications and quality marks are good indicators. Seek suppliers who demonstrate a commitment to quality control.

Evaluating supplier feedback is also essential. An analysis by the Composite Material Industry shows that 45% of businesses consider reviews critical in their decision-making. High customer satisfaction typically correlates with superior product quality. Look for testimonials that highlight product performance. Sometimes, subpar reviews can reveal underlying issues needing attention.

In addition, conducting site visits can provide valuable insights. Seeing production facilities firsthand helps assess quality practices. It also builds trust. However, this can be a challenging task for many. Suppliers may hesitate to allow visits if there are concerns about transparency. Always consider the location and logistics of reaching potential suppliers. The right choice can lead to successful projects and growth opportunities.