-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

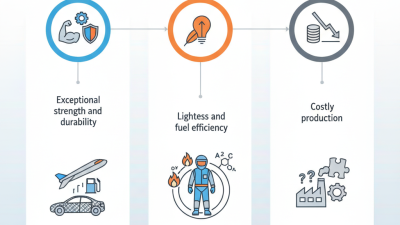

Aramid Fiber Products have gained immense popularity due to their unique properties. These materials offer exceptional strength and heat resistance. According to a report by MarketsandMarkets, the aramid fiber market is expected to reach approximately $5 billion by 2026. This growth is driven by the demand for durable and lightweight materials in various industries.

Choosing the right aramid fiber product can be challenging. It requires careful consideration of specific applications and needs. Misunderstanding the capabilities of aramid fibers can lead to suboptimal choices. It is important to assess mechanical properties and environmental resistance thoroughly. Failure to do so may result in performance issues or increased costs.

Selecting aramid fiber products is not merely about picking any option. The nuances of each product play a critical role in overall effectiveness. Industry experts emphasize the importance of understanding different grades and types. Failing to reflect on these factors could diminish the benefits of using aramid fibers. It is essential to stay informed about new developments in the market, ensuring optimal selections.

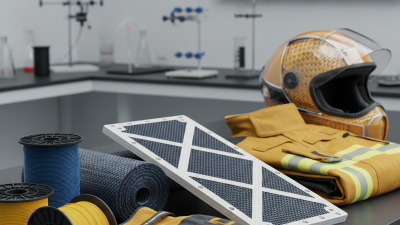

When selecting aramid fiber products, several critical factors come into play. First, consider the specific application. Aramid fibers are versatile and used in various fields. For example, they are popular in protective gear, aerospace, and automotive industries. Each application demands different properties such as strength, heat resistance, and weight. Understanding your specific needs can help narrow down your options significantly.

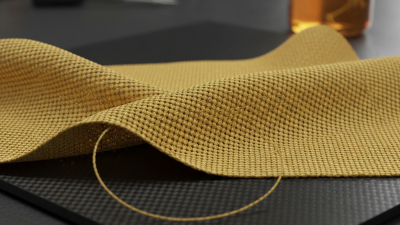

Another important aspect to reflect on is the product's construction. Look closely at how the fibers are woven or layered. Some products may offer higher tensile strength, while others are designed for flexibility. Testing samples can reveal a lot about their performance. Pay attention to manufacturer specifications and certifications, too. These details can indicate the quality and compliance of the product.

Price is a consideration, but don’t let it overshadow quality. Sometimes, cheaper options may not provide the same level of performance. Evaluating the long-term benefits against initial costs is essential. Keep in mind, not all aramid fibers are created equal. Some may degrade faster under certain conditions, leading to significant future expenses. Always ask questions and seek expert advice when unsure. Selecting the right aramid fiber can make a difference in durability and safety.

When exploring aramid fibers, it's essential to understand their different types. Two common types are para-aramid and meta-aramid. Para-aramid fibers are known for high strength and heat resistance. They are often used in bulletproof vests and industrial applications. In contrast, meta-aramid fibers have lower strength but improved thermal stability. They are ideal for electrical insulation and heat-resistant garments.

Choosing the right aramid fiber product can be challenging. Consider the specific application you need it for. If you need something robust and durable, para-aramid might be the better choice. For lighter protective gear or insulation, meta-aramid can be sufficient. Don't forget to check the thickness and weave of the fibers. Materials vary in weight and flexibility.

When picking aramid products, look beyond the surface. Evaluate environmental factors, such as exposure to chemicals or intense heat. The right choice might not always be obvious. Sometimes, what seems strong can fail under pressure. Consult with experts, and perhaps sample a few options. Make sure to reflect on how each product aligns with your needs.

When evaluating aramid fiber products, performance characteristics are crucial. These fibers are renowned for their high strength-to-weight ratio. According to the Composite Materials Handbook, aramid fibers can exhibit tensile strengths exceeding 3,000 MPa. This makes them ideal for applications where lightweight and strength are essential. However, one must not solely focus on strength.

Thermal stability is another key factor. Aramid fibers can withstand temperatures up to 250°C without significant loss of mechanical properties. Recent studies show that this thermal resistance empowers them to perform in extreme conditions—essential for aerospace and military applications. Yet, users often overlook water absorption rates, which can affect the fiber's long-term durability. Some aramid products absorb moisture, leading to dimensional instability.

Lastly, consider the aging properties of these fibers. While they resist UV light, some aramid fibers can degrade over time with prolonged exposure. Recent reports suggest a 20% reduction in tensile strength after five years of exposure in certain environments. Evaluating these nuances is vital for making informed choices. Proper assessment helps ensure that the selected products meet all performance expectations.

| Criteria | Description | Importance |

|---|---|---|

| Tensile Strength | Ability to withstand pulling forces without breaking. | High |

| Heat Resistance | Resistance to degradation in high temperatures. | High |

| Chemical Resistance | Ability to resist damage from chemicals and solvents. | Medium |

| Weight | Lightweight properties for ease of use and reduced fatigue. | Medium |

| Durability | Long-lasting performance under adverse conditions. | High |

| Flexibility | Ability to bend without cracking or breaking. | Medium |

| Abrasion Resistance | Resistance to wear from friction with other materials. | High |

| Electrical Insulation | Ability to act as an insulator for electrical applications. | Medium |

| Cost | Consideration of price versus performance ratio. | High |

| Compatibility | Suitability for intended applications and environments. | High |

When considering aramid fiber products, the balance between cost and quality is crucial. A recent industry report indicated that high-quality aramid fibers have a tensile strength of about 3.6 GPa. This characteristic plays a significant role in performance. However, cheaper alternatives may not meet these standards, leading to safety and durability concerns.

The cost of aramid fibers can vary significantly. Some premium products can cost over $20 per kg, while lower-quality options may be priced below $10 per kg. While the initial savings may seem appealing, subpar materials can lead to increased long-term costs. Maintenance and replacement often outweigh the initial savings, especially in high-stress applications like aerospace and defense.

Investing in quality can mean better performance and reliability. Yet, some companies overlook the details in their procurement process. They may choose lower-cost options without fully assessing the implications. Reports highlight that poor-quality fibers can fail under extreme conditions, resulting in potential hazards. It’s vital to consider the long-term effects rather than short-term savings when selecting aramid fiber products.

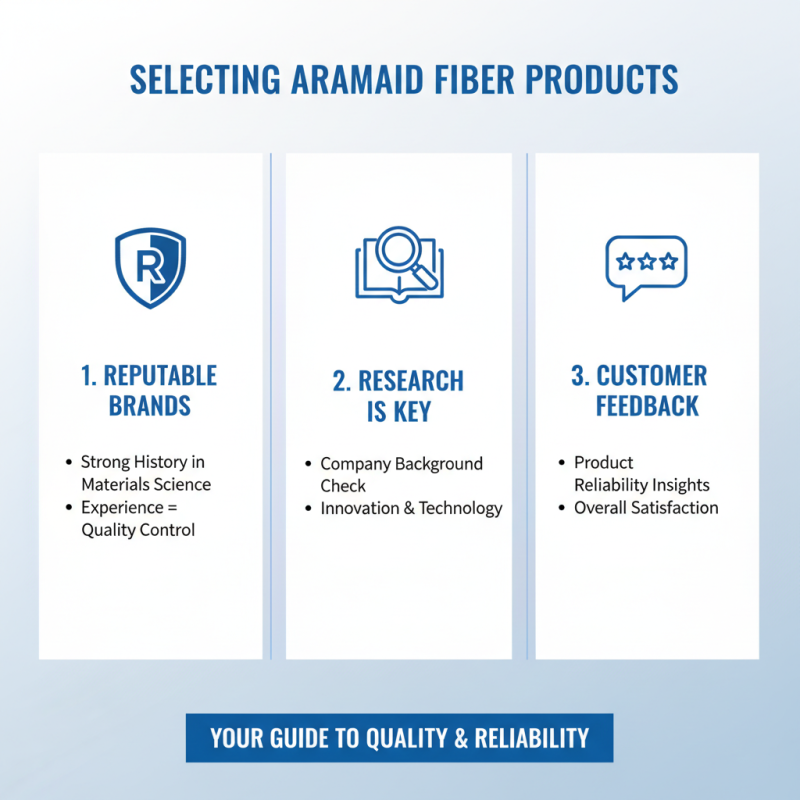

When selecting aramid fiber products, identifying reputable brands and manufacturers is crucial. Research is key. Look for companies with a strong history in materials science. Quality control is often a reflection of their experience. Pay attention to customer reviews and feedback. This can provide valuable insights into product reliability.

Consider certifications and standards. Reputable manufacturers often adhere to industry guidelines. These certifications can indicate quality and safety. Visual inspection of products is also important. Check for consistent color and texture. Inconsistent features might suggest poor production practices.

Networking within industry forums can help. Engage with professionals who have experience with aramid fibers. They can offer recommendations based on their experiences. Sometimes, new brands may surprise you with innovation. However, caution is needed. Not every newcomer is trustworthy. Always do your due diligence to ensure you make informed choices.