-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Uhmwpe Fiber Fabric has gained significant attention in various sectors. This high-performance material is known for its exceptional strength and durability. Industry experts project the global market for Uhmwpe Fiber Fabric to grow steadily. According to a report by Grand View Research, the market was valued at approximately $1.2 billion in 2022.

Dr. Emily Anderson, a leading expert in advanced fabrics, emphasizes its versatility: "Uhmwpe Fiber Fabric transforms industries with its unmatched properties." This remarkable material is used in protective clothing, marine applications, and defense gear. Its lightweight nature, combined with a high strength-to-weight ratio, makes Uhmwpe Fiber Fabric a preferred choice for manufacturers.

However, there are challenges in its production and sustainability. The environmental impact remains a concern as the industry seeks eco-friendly solutions. Looking forward, innovations in Uhmwpe Fiber Fabric must address both performance and sustainability to meet future demands.

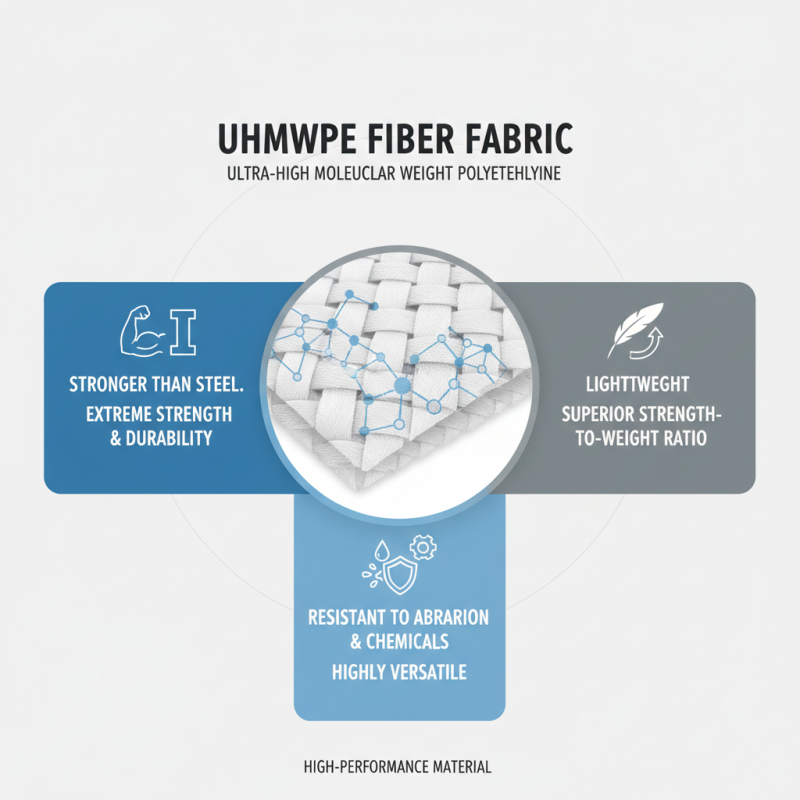

Uhmwpe fiber fabric is a high-performance material. It stands for ultra-high molecular weight polyethylene. This fiber is known for its exceptional strength and durability. It is significantly stronger than steel, yet lightweight. The fabric is also resistant to abrasion and chemicals, making it highly versatile.

One key feature of Uhmwpe fiber fabric is its low friction coefficient. This allows it to be used in various applications. For instance, it is commonly used in protective gear. This includes bulletproof vests and helmets. Its strength is crucial in life-saving situations. However, the production process is complex. Not all manufacturers produce it consistently. Quality can vary, which leads to challenges in performance across different products.

Moreover, Uhmwpe fiber fabric has environmental concerns. The production process may involve harsh chemicals. It's important to consider sustainable practices in production. The lifecycle of these fabrics obviously requires re-evaluation as well. While its benefits are clear, there are still areas needing improvement and reflection.

Uhmwpe fiber, or ultra-high molecular weight polyethylene, is known for its impressive properties. This fiber boasts high tensile strength, making it one of the strongest synthetic fibers available. It is lightweight yet incredibly durable. Uhmwpe fibers can withstand extreme temperatures. They resist abrasion and chemicals, making them suitable for a wide range of applications.

One notable characteristic of Uhmwpe fiber is its low moisture absorption. This quality allows it to maintain its strength even in wet conditions. Additionally, the fiber is UV resistant, which helps to prevent degradation from sunlight. These features make it ideal for outdoor gear and protective clothing. However, working with Uhmwpe requires careful attention. Its rigidity can pose challenges during manufacturing.

The fiber’s applications are diverse. It can be found in ropes, sails, and armor, showcasing its versatility. Despite its strengths, some manufacturers report difficulties in dyeing Uhmwpe fabrics. This can limit design options. Therefore, while Uhmwpe fibers excel in performance, their usability may bring some challenges.

UHMWPE Fiber Fabric, or Ultra-High Molecular Weight Polyethylene, is gaining traction in various industries due to its impressive properties. One significant area of application is in personal protective equipment (PPE). Studies indicate that these fabrics can provide up to 15 times the wear resistance of steel, making them ideal for cut-resistant gloves and vests. This increased durability enhances worker safety in hazardous environments.

Another common use of UHMWPE fiber fabric is in the manufacturing of ropes and cables. The strength-to-weight ratio is remarkable, with these fibers boasting a tensile strength five times greater than steel at just a fraction of the weight. Boats, rescue operations, and construction sites benefit massively from this innovation. However, some challenges persist, such as the high production costs and limited processing techniques available. This can restrict widespread adoption in lower-budget projects.

Moreover, the use of UHMWPE in ballistic protection gear cannot be overlooked. Fabrics engineered with these fibers are significantly lighter than traditional materials, reducing fatigue for users. Nonetheless, the technology still faces scrutiny regarding its long-term performance under extreme conditions. Continuous research and development are critical to maximize its potential across different industries.

| Application | Description | Benefits |

|---|---|---|

| Ballistic Protection | Used in armor systems for personal and vehicle protection. | High strength-to-weight ratio and flexibility. |

| Marine Applications | Utilized in ropes and nets for fishing and shipping industries. | Resistance to abrasion and UV light. |

| Medical Devices | Applied in surgical sutures and wound dressings. | Biocompatible and strong. |

| Industrial Applications | Used in conveyor belts and protective gear. | Durable and resistant to chemicals. |

| Aerospace | Incorporated in lightweight composites for aircraft. | Reduces weight while enhancing strength. |

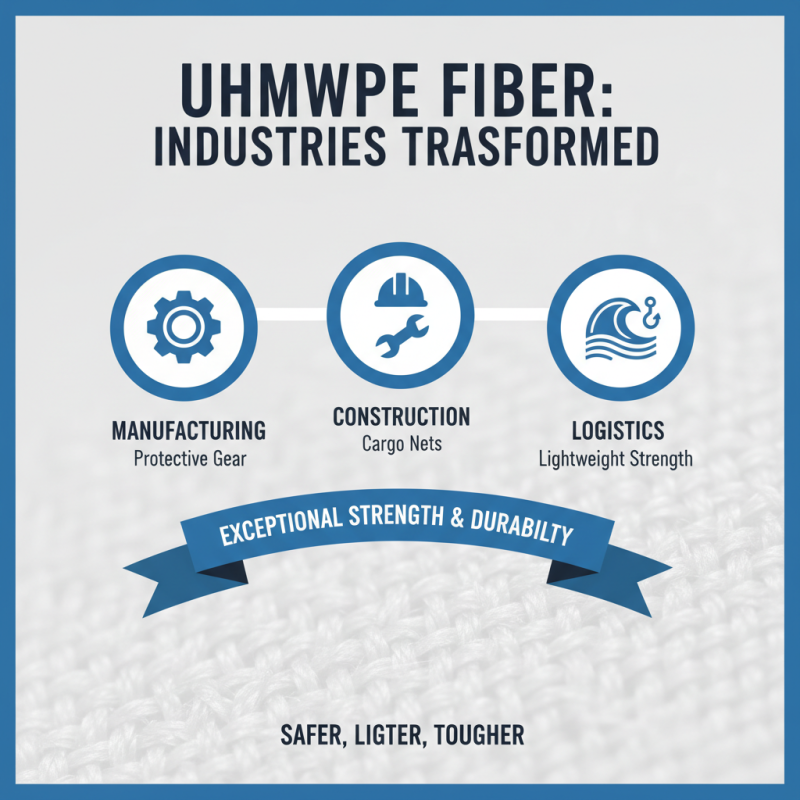

Uhmwpe fiber fabric is making waves across various industries. Its exceptional strength and durability are key features. In industries like manufacturing and construction, this fabric offers significant benefits. It is lightweight yet incredibly tough, making it ideal for protective gear and cargo nets. Workers benefit from added safety without the weight drag.

In the marine sector, Uhmwpe is used in ropes and lines. These products resist abrasion and UV damage. The longevity of such materials reduces replacement costs over time. However, one must consider proper disposal methods. While durable, they can contribute to waste issues if not handled correctly.

When choosing Uhmwpe fiber products, ensure quality checks are in place. Be aware of how different environments may affect performance. Regular inspections and maintenance help in identifying wear and tear. A proactive approach can save time and resources, reducing long-term risks.

Uhmwpe fiber products are known for their strength and durability. However, proper maintenance is crucial for longevity. Regular cleaning is essential. Use mild soap and water. Avoid harsh chemicals as they can damage the fibers.

Drying these fabrics requires care. Lay them flat to dry to prevent distortion. High heat can weaken the fibers, so air drying is preferred. Store Uhmwpe items in a cool, dry place away from direct sunlight. Prolonged exposure to UV light may cause fading and degradation.

Inspect your Uhmwpe products regularly for any signs of wear. Look for frayed edges or discoloration. It’s better to address small issues early. Remember, these materials are tough, but they will not last forever without care. Periodic maintenance will help preserve their quality over time.