-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Uhmwpe Fiber Fabric has emerged as a revolutionary material in various industries, with applications expanding rapidly. By 2026, it is projected that the global market for Uhmwpe Fiber Fabric will reach approximately $2 billion, driven by its exceptional strength and lightweight properties. According to a recent report by Technavio, the rising demand for ballistic protection gear is a major contributor to this growth. Experts agree that Uhmwpe Fiber Fabric stands out due to its unmatched durability compared to traditional fabrics.

Dr. Emily Johnson, a leading figure in polymer science, emphasizes its potential: "Uhmwpe Fiber Fabric is redefining how we approach protective wear and industrial applications." This material is already being utilized in various sectors, including military, sports, and transportation. However, challenges remain in production scalability and cost-effectiveness. Some manufacturers struggle with consistent quality, making it imperative to refine production processes.

While the future looks promising for Uhmwpe Fiber Fabric, these hurdles demand attention. As the industry evolves, stakeholders must focus on innovation to harness this material's full potential. The continuous development and application of Uhmwpe Fiber Fabric will likely transform our approach to safety and performance.

Uhmwpe fiber fabric, or ultra-high-molecular-weight polyethylene, is known for its incredible strength and versatility. This synthetic material has a high tensile strength-to-weight ratio. It is often used in various industries for its durability and resistance to abrasion. Reports indicate that Uhmwpe fibers are five times stronger than steel, making them particularly valuable in high-performance applications.

Uhmwpe fiber fabric is non-toxic and environmentally friendly. It withstands extreme temperatures and harsh environments. This fiber is commonly utilized in personal protective equipment, such as vests and helmets, providing essential safety features. Furthermore, it finds applications in maritime industries, including ropes and nets, where resilience is crucial. The global market for Uhmwpe fibers is expected to grow significantly, with predictions estimating a compound annual growth rate of around 7.3% by 2026.

Tips: Consider using Uhmwpe fabric in safety gear to enhance protection without adding weight. Invest in materials known for their long lifespan. This way, you minimize replacement costs and waste. Remember, not all Uhmwpe fabrics meet the same standards. Always review specifications before purchase.

Uhmwpe (Ultra High Molecular Weight Polyethylene) fiber fabric is known for its outstanding properties. This material boasts an exceptional tensile strength, making it five times stronger than steel. Lightweight yet highly durable, Uhmwpe is resistant to abrasion and impact. Industrial reports indicate that this fabric remains stable in extreme temperatures, which enhances its versatility in various applications.

The key properties include a low coefficient of friction and excellent chemical resistance, which makes it suitable for hostile environments. The fiber is non-toxic, adding to safety in use. With these attributes, Uhmwpe fiber fabric is increasingly chosen for military and industrial applications. Innovative sectors like sports gear and protective clothing also benefit from this technology.

Despite its advantages, the production of Uhmwpe can be resource-intensive. The process may generate waste and consume energy. As applications for this material expand, the industry faces the challenge of balancing performance with sustainability. Improving manufacturing efficiency is essential. The future will require ongoing innovation to address environmental concerns.

| Property | Description | Applications |

|---|---|---|

| High Strength | UHMWPE fibers are known for their exceptional strength, making them suitable for various demanding applications. | Protective Gear, Ropes |

| Lightweight | These fibers are lightweight compared to steel, providing an advantage in construction and apparel. | Aerospace, Sports Equipment |

| Chemical Resistance | UHMWPE fibers resist many chemicals, enhancing their durability in hostile environments. | Medical Applications, Industrial Fabrics |

| Low Friction | The low coefficients of friction make UHMWPE fibers suitable for sliding applications. | Marine Applications, Conveyor Belts |

| Thermal Stability | UHMWPE fibers maintain their properties over a wide temperature range. | Fire-Resistant Clothing, Heat Shields |

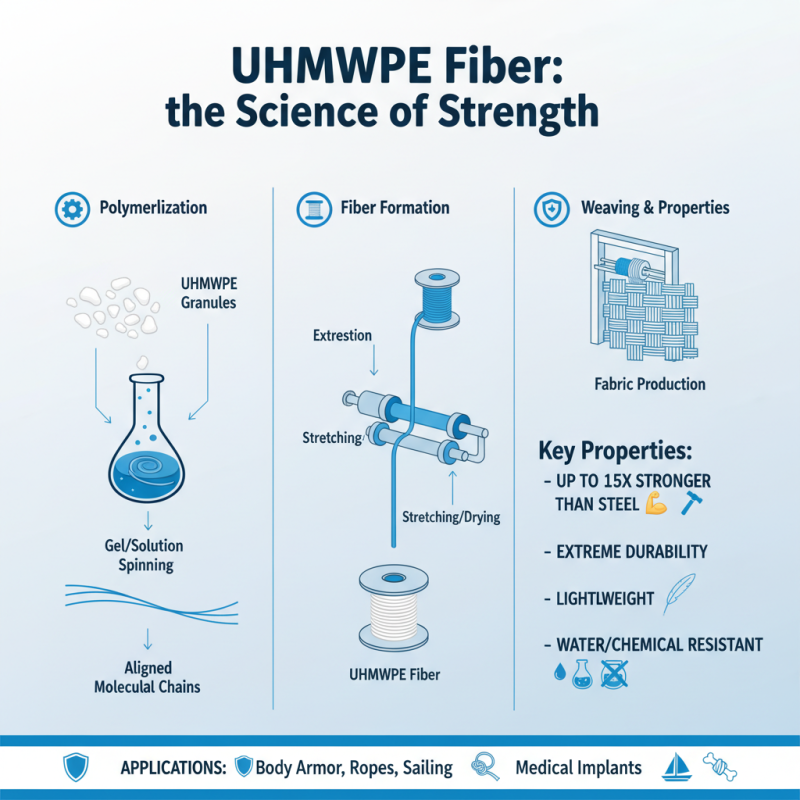

Uhmwpe fiber fabric is known for its remarkable strength and durability. The manufacturing process is critical to achieving these properties. Typically, it begins with the polymerization of ultra-high molecular weight polyethylene (UHMWPE) granules. This process can be done through various techniques, including gel spinning and solution spinning. Gel spinning allows for better alignment of molecular chains, resulting in superior tensile strength, which gets reported to be up to 15 times stronger than steel.

After fiber production, the next stage involves weaving or knitting. These methods determine the final fabric characteristics, such as flexibility and resilience. Most fabrics undergo treatments to enhance UV resistance and water repellency. A study from the Textile Research Journal suggests that treated Uhmwpe fabrics exhibit a remarkable increase in performance under harsh conditions. The variety in production techniques allows manufacturers to cater to multiple industries, ensuring a versatile application range.

However, challenges persist in the industry. The initial costs of raw materials and sophisticated machinery can lead to reduced accessibility for smaller manufacturers. Sustainability also poses questions, as the eco-footprint of UHMWPE production is under scrutiny. Companies are exploring recycling options but face technical barriers. The market demands innovative solutions to make the production process greener, highlighting the ongoing need for reflection and adaptation in this thriving field.

Uhmwpe fiber fabric is gaining significant attention. This material is known for its exceptional strength and low weight. In 2026, various industries will adopt it for innovative applications. One major area will be protective clothing. Workers in hazardous environments need reliable gear. Uhmwpe fabric offers superior puncture and cut resistance. This can enhance safety and performance significantly.

Another promising application lies in sports gear. Athletes require lightweight, durable materials to enhance their performance. Uhmwpe fibers could revolutionize equipment like helmets and pads. The comfort and flexibility it provides will be crucial. However, challenges remain with production costs and scalability. Manufacturers must work on affordable solutions.

The automotive industry will also explore Uhmwpe fiber. Lightweight components can improve fuel efficiency. Yet, concerns about long-term durability need addressing. Engineers must ensure that these materials withstand extreme conditions. Uhmwpe fiber fabric has potential, but there are hurdles. Balancing performance with cost will be essential. These applications show promise but require careful consideration and innovation.

Uhmwpe fiber fabric is gaining significant traction in various industrial sectors. By 2026, the growth of this material is projected to increase dramatically. A report by Technavio estimates a compound annual growth rate (CAGR) of 9.4% for the UHMWPE market. This trend suggests a robust demand for its unique properties, including high tensile strength and low weight.

In the automotive and aerospace industries, UHMWPE fabric is particularly valued for its lightweight and durable qualities. These fabrics can reduce vehicle weight, leading to better fuel efficiency. Many manufacturers are exploring innovative applications, but challenges remain. The production process can be complex, and costs may hinder widespread adoption.

Further, the protective gear sector is increasingly utilizing UHMWPE for its impressive abrasion resistance. Reports indicate a growing interest in safety equipment made from this fiber, which offers excellent protection without sacrificing comfort. However, one must question the environmental impact of sourcing and producing Uhmwpe. As the demand grows, securing sustainable practices will be crucial for long-term viability. Industry players face pressure to balance innovation with environmental responsibilities while meeting consumer expectations.