-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

When it comes to modern engineering and design, the significance of materials cannot be overstated. Among the myriad options available, Carbon Fiber Tubes stand out due to their unparalleled strength-to-weight ratio and versatility. This lightweight yet robust material has captivated industries ranging from aerospace to automotive and sports equipment, making it a preferred choice for many applications. However, navigating the world of carbon fiber can be daunting, especially for those looking to select the right product for their specific needs.

In this ultimate guide, we will provide you with essential insights into choosing the right Carbon Fiber Tube. Whether you are a seasoned professional or a newcomer to the industry, understanding the key factors that influence your decision will help you make informed choices that align with your project requirements. From considering the tube's diameter and wall thickness to evaluating its mechanical properties, our ten tips will equip you with the necessary knowledge to optimize your selection process. Join us as we delve into the intricacies of carbon fiber, empowering you to harness its full potential in your innovative endeavors.

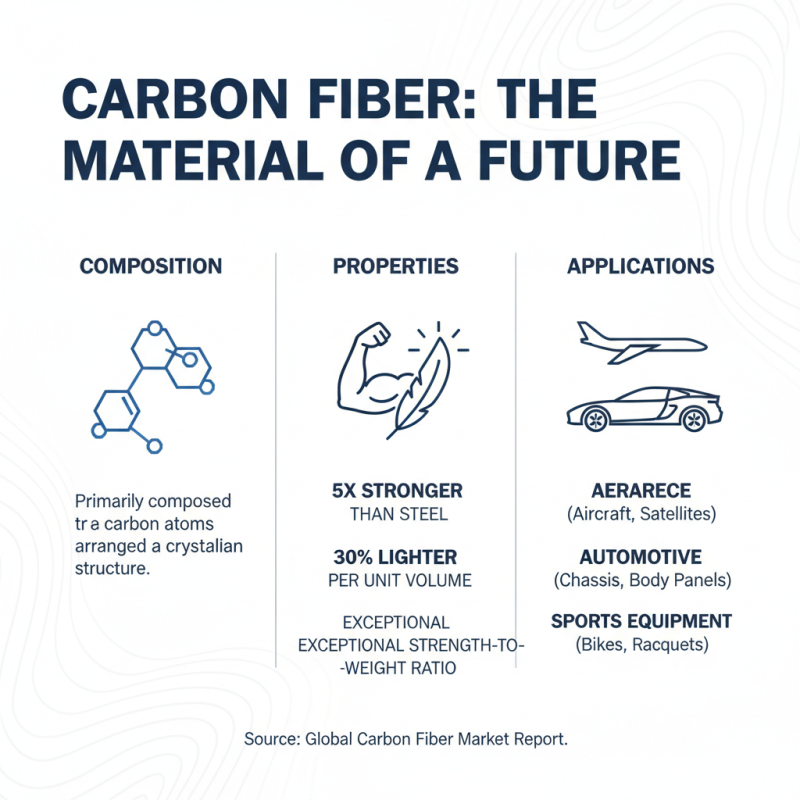

Carbon fiber has become a vital material across various industries, thanks to its unique composition and outstanding properties. Primarily composed of carbon atoms arranged in a crystalline structure, carbon fiber exhibits exceptional strength-to-weight ratios, making it a top choice for applications ranging from aerospace to automotive. According to a report by the Global Carbon Fiber Market, the material can be five times stronger than steel while being significantly lighter—roughly 30% lighter per unit volume. This combination allows manufacturers to create lightweight but robust products, leading to increased fuel efficiency and performance in vehicles and aircraft.

In addition to its remarkable strength, carbon fiber boasts excellent stiffness and thermal resistance. The modulus of elasticity for carbon fiber can be significantly higher than that of metals, indicating its ability to maintain shape under stress. Research released by the Carbon Fiber Composite Materials Market states that the thermal stability of carbon fiber allows it to withstand temperatures exceeding 250°C without deforming. This quality is particularly beneficial in environments requiring durability under high temperatures or fluctuating thermal conditions. Overall, understanding these properties is crucial when choosing the right carbon fiber tube for specific applications, ensuring performance and longevity.

Carbon fiber tubes have become increasingly important across various industries due to their unique properties, including high strength-to-weight ratios and excellent resistance to fatigue and corrosion. In the aerospace sector, for instance, reports indicate that the use of carbon fiber composites has led to weight reductions of approximately 30% in certain aircraft components. This results in significant fuel savings and improved overall performance, which is crucial for both commercial and military applications.

In the sporting goods industry, carbon fiber tubes are favored for their lightweight characteristics and rigidity. Products like bicycles and golf clubs utilize carbon fiber to enhance performance; studies have shown that bicycles made from carbon fiber can be 15-20% lighter than their aluminum counterparts. This reduction in weight without sacrificing strength allows athletes to achieve better speeds and efficiencies. Additionally, the automotive industry is also harnessing the advantages of carbon fiber tubing, with data from market analyses forecasting a compound annual growth rate (CAGR) of over 15% for carbon fiber applications in vehicles from 2021 to 2026. This trend underscores the material’s potential for contributing to more fuel-efficient and high-performance automotive designs.

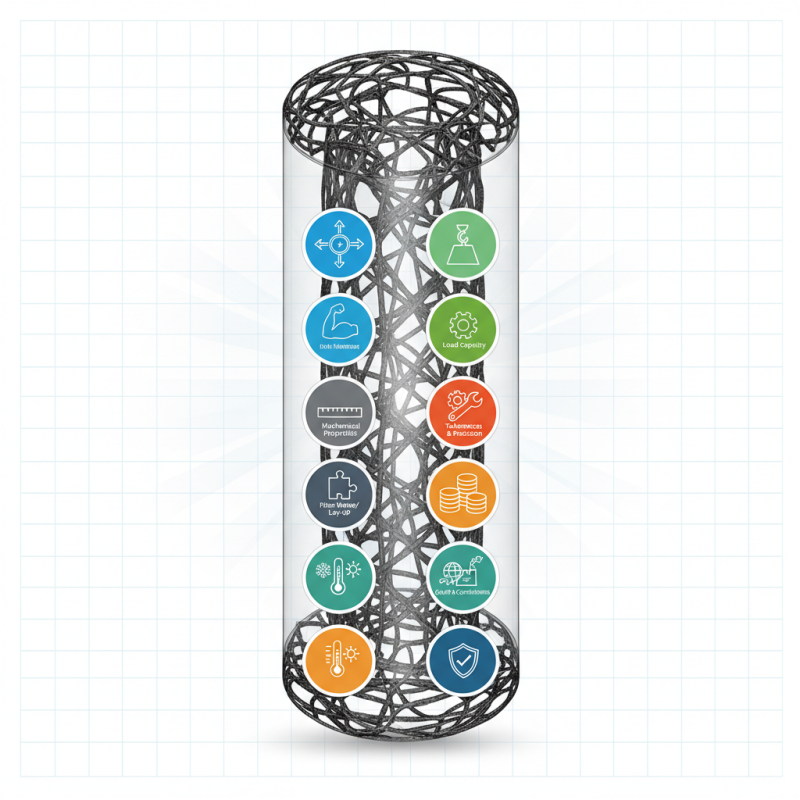

When selecting carbon fiber tubes, various factors play a critical role in determining their overall performance. One of the primary factors is the fiber orientation and layup configuration, which influences the tensile strength and stiffness of the tube. According to a report by Composites World, carbon fiber materials can exhibit a tensile strength ranging from 300 to 600 ksi, depending on the fiber type and how it is oriented in the composite. This makes understanding layup techniques essential for engineers designing applications ranging from aerospace to sporting goods.

Another significant factor is the resin system used in conjunction with the carbon fibers. The resin affects the bonding between fibers and can influence the thermal and chemical resistance properties of the final product. For instance, a study published in the Journal of Composite Materials indicates that epoxy resin systems significantly enhance the performance of carbon fiber composites compared to polyester resins, offering improved durability and weather resistance. Additionally, the manufacturing process, such as roll-wrapping or filament winding, also impacts the fiber alignment and density, which ultimately contribute to the strength and load-bearing capacity of the tubes. Ensuring proper selection based on these performance-influencing factors is essential for achieving optimal results in any application utilizing carbon fiber tubes.

When evaluating the cost-effectiveness of carbon fiber tubes, one must consider a variety of factors that influence both their initial investment and long-term value. According to a report from the Composites Industry Association, carbon fiber components can be up to 10 times stronger than traditional materials like aluminum, allowing for significant weight savings and efficiency improvements in various applications. This strength-to-weight ratio translates to lower energy consumption and enhanced performance, particularly in industries like aerospace and automotive, where every gram matters.

Tip 1: Always assess the specific mechanical properties required for your application. Different carbon fiber tubes offer varying levels of tensile strength, stiffness, and flexibility, which can directly impact their performance and suitability for your project.

Another crucial aspect of cost-effectiveness is the longevity and durability of carbon fiber tubes. A study conducted by the American Society for Composites found that carbon fiber materials can have a lifespan that exceeds 40 years with proper maintenance, reducing the need for frequent replacements and associated costs.

Tip 2: Evaluate the manufacturing processes involved. Advanced production techniques, while initially more expensive, can lead to significant savings in terms of waste reduction and efficiency. Investing in high-quality carbon fiber tubes from the outset may offer better long-term performance and reliability.

In conclusion, while the upfront costs of carbon fiber tubes may be higher than traditional materials, their exceptional performance characteristics and potential for cost savings over time make them a compelling choice for many applications.

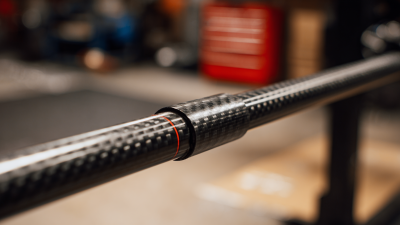

When selecting and maintaining carbon fiber tubes, it's essential to consider several best practices to ensure optimal performance and longevity. First, when choosing a carbon fiber tube, always assess its intended application. Different projects may require tubes with varied flexural strength, stiffness, and weight. Understanding these requirements will help you select the most suitable option for your needs.

Another crucial factor is to inspect the tube for any imperfections or damages before purchasing. Small flaws can significantly impact the tube's performance and durability. Additionally, regular maintenance is key to extending the life of the carbon fiber tubes. It’s advisable to clean them with a mild detergent and soft cloth to avoid scratching the surface.

Proper storage also plays a significant role in the longevity of carbon fiber tubes. Ensure they are kept away from direct sunlight and harsh environmental conditions, which can degrade the material over time. When handling, always use gloves to prevent oils from your skin from affecting the resin finish. These simple yet effective tips will help you maintain the integrity of your carbon fiber tubes while ensuring their effectiveness in various applications.