-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Carbon Fiber Fabric has gained immense popularity in various industries due to its unique properties. This lightweight material is not only strong but also offers excellent resistance to corrosion. According to a report by MarketsandMarkets, the global carbon fiber market is projected to reach $5.8 billion by 2025. Such growth highlights the increasing demand for versatile materials in aerospace, automotive, and sporting goods.

Using Carbon Fiber Fabric in your projects can enhance durability and performance. It is crucial to understand its application techniques. Many experts recommend combining it with other materials for optimal results. However, improper handling can lead to issues. For instance, misalignment during layering can weaken structural integrity. Therefore, precision is key.

Challenges also exist in sourcing quality Carbon Fiber Fabric. Some manufacturers may cut corners, affecting the final product's quality. Be sure to vet suppliers thoroughly. Though Carbon Fiber Fabric presents incredible benefits, remaining aware of these precautions can lead to better project outcomes.

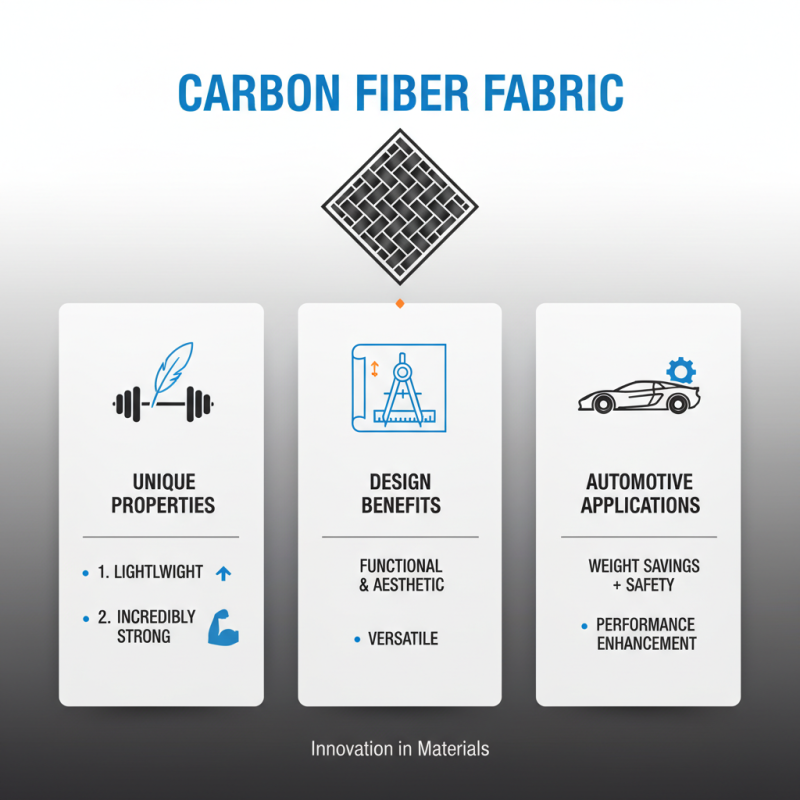

Carbon fiber fabric is known for its unique properties that make it popular in various projects. It's lightweight but incredibly strong. This combination allows for designs that are both functional and aesthetically pleasing. When used in automotive applications, carbon fiber can provide significant weight savings without compromising safety.

Its resistance to corrosion and temperature also makes carbon fiber ideal for outdoor projects. You could use it for sports equipment, where performance is crucial. However, working with carbon fiber can be challenging. The material is tricky to cut and shape, often requiring specialized tools.

Take time to learn about proper techniques. Mistakes can lead to wasted materials. Even experienced users sometimes struggle with achieving smooth finishes. Experiment with different approaches to find what works best for your specific needs. Each project can teach you something new about this fascinating material.

Carbon fiber fabric is transforming various industries with its lightweight and durable properties. In aerospace, it’s a game-changer. Aircraft parts made from carbon fiber are significantly lighter than those made from traditional materials. This weight reduction improves fuel efficiency. However, manufacturing can be costly. Balancing quality and cost is essential.

In the automotive sector, carbon fiber is gaining traction. Many high-performance vehicles use it for body panels and interior components. This enhances speed and reduces weight, but repairs can be tricky. Specialized skills are often required, which can pose a challenge for some manufacturers.

Tips: When working with carbon fiber, wear protective gear. The material can splinter and cause injuries. Always work in a well-ventilated area to avoid inhaling harmful dust.

In sporting goods, carbon fiber is prevalent. From bicycles to tennis rackets, its strength and lightness boost performance. Quality can vary greatly between products. Researching materials and construction methods is vital to ensure you’re getting the best.

Tips: Experiment with different layers and weaves. Finding the right balance can enhance your project. Always consider the end-use; it can dictate the type of carbon fiber to use.

Selecting the right carbon fiber fabric for your project can be daunting. It's vital to understand the types available. There are woven, uni-directional, and multi-axial fabrics. Each has unique properties. For instance, woven carbon fiber is often more flexible and easier to handle. According to a market report, the global carbon fiber market is projected to grow at a CAGR of 9.3% until 2026. This indicates increasing applications in various sectors.

Consider the weight and thickness of the fabric. A lighter fabric may be beneficial for projects where weight is critical, such as in aerospace applications. However, more substantial fabrics can offer enhanced strength. A balance is often difficult to achieve. Pay attention to the fabric's resin compatibility. Not all resins work well with every fabric type. A mismatch can lead to weak bonding.

Testing samples before committing is a practical approach. This allows for adjustments. You might find that a fabric looks good but doesn’t perform under stress. Many novices overlook this step. Careful evaluation can save time and resources. Observing project requirements closely is key. Sometimes, more is not better. The right carbon fiber fabric should align with your project's specific needs and constraints.

| Type of Carbon Fiber Fabric | Weight (g/m²) | Thickness (mm) | Applications | Properties |

|---|---|---|---|---|

| Plain Weave | 200 | 0.19 | Aerospace, Automotive | High Strength, Stiffness |

| Twill Weave | 240 | 0.21 | Sports Equipment, Bicycles | Flexibility, Aesthetic |

| Uni-Directional | 300 | 0.24 | Boat Hulls, Wind Turbines | High Tensile Strength |

| Sandwich Panel | 500 | 0.30 | Structural Components | Lightweight, High Rigidity |

Cutting and shaping carbon fiber requires precision. Depending on the project's needs, the method varies. For instance, using a diamond-tipped saw can ensure clean edges. However, achieving a perfect cut can be tricky. Users must take extra care to avoid jagged edges. This can lead to structural weaknesses, affecting overall performance.

When it comes to shaping, heat forming is an effective method. It allows for bending without breaking. Yet, controlling the heat is vital. Too much can damage the material. Research indicates that improper heating may weaken the fibers. Additionally, some practitioners report challenges with maintaining a consistent shape throughout the process.

Hand tools can also be beneficial for smaller projects. A simple rotary tool can provide versatility. Nevertheless, this approach can be time-consuming. Mistakes are common, as the fabric can fray if not handled correctly. Many enthusiasts discover that meticulous practice improves their cutting techniques. This is where learning from failure becomes crucial. Analyzing past projects may help refine skills and achieve better results in the future.

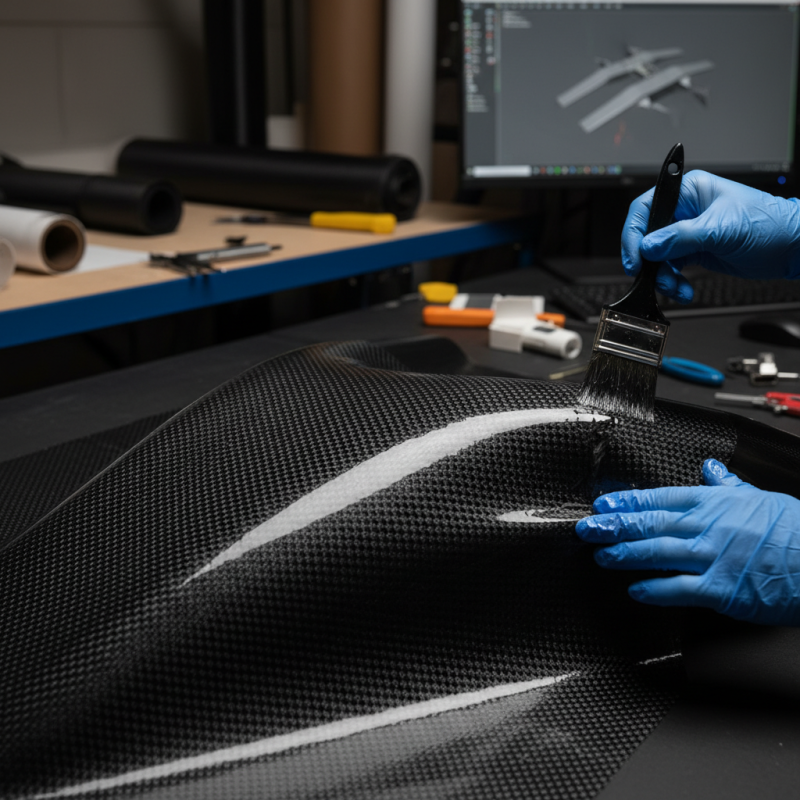

When working with carbon fiber fabric, bonding and finishing techniques are crucial. Begin by preparing the surfaces. Clean them thoroughly to remove dust and grease. A smooth surface ensures better adhesion. Apply a suitable epoxy resin to the carbon fiber. Use a brush or roller for even distribution. Be careful; bubbles may form. They can weaken the bond.

After the initial bonding, focus on the finishing touches. Trim excess fabric carefully; a sharp blade is essential. Sand the edges lightly for a clean look. Some imperfections may remain. It’s important to assess these areas and decide whether they meet your project standards.

To achieve a consistent finish, consider applying a clear coating. This helps protect the fabric and enhances its appearance.

Remember, every project is a learning experience. If the finish isn’t perfect, reflect on what to improve next time.

Each attempt with carbon fiber teaches new techniques and skills.