-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Carbon Fiber Laminate Sheet is a versatile material. It is lightweight yet incredibly strong, making it ideal for various projects. Many people use this material in automotive, aerospace, and sporting goods industries.

When working with Carbon Fiber Laminate Sheet, it’s important to understand its properties. These sheets can be cut, shaped, and layered to suit specific needs. However, one must be cautious when handling the material. Sometimes, it can be difficult to manage because of its rigidity. Not everyone will achieve perfect results on the first try.

Planning your project with Carbon Fiber Laminate Sheet requires creativity and precision. Think about your design and how you will use the sheet. Explore the possibilities and embrace the challenges. Each use can teach you something new about this material.

Carbon fiber laminate sheets are gaining popularity in various projects due to their unique properties. These sheets are lightweight, strong, and resistant to various environmental conditions. Their stiffness makes them ideal for applications requiring high strength-to-weight ratios. Additionally, they resist corrosion, offering enhanced durability. These characteristics make them suitable for both industrial and creative uses.

When working with carbon fiber, it’s essential to understand its limitations. The material can be brittle if not layered properly. Improper handling may lead to stress fractures. Therefore, consider practicing on smaller pieces before tackling larger projects. Accurate cutting and layering can enhance the final product's strength.

Tips: Always wear protective gear when cutting or layering carbon fiber. The fibers can be harmful when airborne. Additionally, use a sharp blade to prevent fraying. Lastly, take time to plan your design. Sketching your layout can save materials and time. Mistakes might occur, but learning from them will improve future projects. Embrace the challenges, and the results will be rewarding.

| Property | Description | Benefits |

|---|---|---|

| Weight | Lightweight material | Reduces overall project weight |

| Strength | High tensile strength | Increases durability and longevity |

| Flexibility | Can be shaped or molded | Allows for creative designs |

| Corrosion Resistance | Resistant to chemicals and moisture | Longevity in harsh environments |

| Thermal Stability | Maintains integrity under temperature changes | Ideal for various climate conditions |

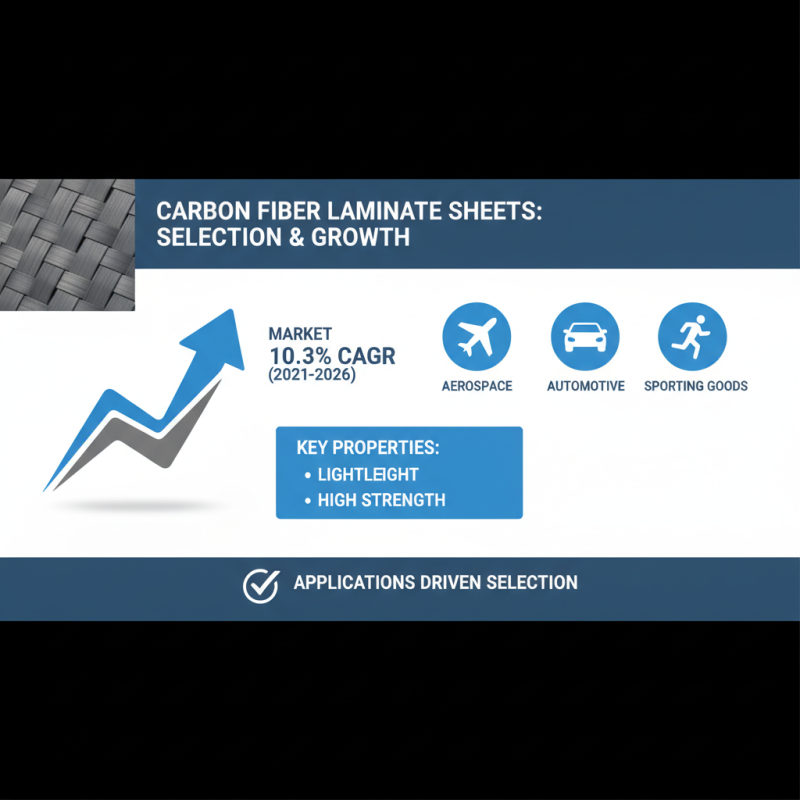

Carbon fiber laminate sheets are incredibly versatile and widely used across various industries. In the aerospace sector, for instance, these sheets contribute to weight reduction while maintaining strength. Reports indicate that the aerospace sector is expected to benefit from a 5% CAGR in carbon fiber composites over the next five years. This growth is propelled by continuous advancements and innovations in manufacturing techniques, enhancing durability.

The automotive industry also harnesses the potential of carbon fiber laminate sheets. As manufacturers aim for lighter vehicles, carbon fiber helps in achieving fuel efficiency. According to industry data, carbon fiber usage in automotive applications is projected to rise, accounting for over 20% of composite material usage by 2025. This shift emphasizes the importance of integrating carbon fiber for vehicle performance and sustainability.

Tips: When selecting carbon fiber laminate sheets, consider the thickness and weave type according to your project's requirements. Testing the material before large-scale applications can avoid unexpected failures. While carbon fiber offers superior strength, it’s essential to ensure proper handling during installation to limit any structural weaknesses.

When selecting the right carbon fiber laminate sheet, consider its applications. Carbon fiber is known for its lightweight nature and high strength. Reports indicate that the carbon fiber market is expected to grow annually by 10.3% from 2021 to 2026. This increase reflects its potential across aerospace, automotive, and sporting industries.

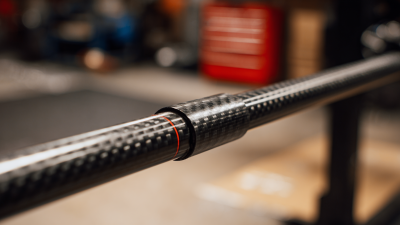

Think about the thickness and weave of the laminate. A 3K weave offers decent flexibility while maintaining strength. For more structural applications, consider unidirectional options. The choice of epoxy resin also plays a crucial role in durability. Each project's requirements may vary. A wrong choice could lead to failures.

Test your choices with samples. Never skip this step. Understanding how materials interact under stress is vital. Not every laminate will suit your specific needs. Adjustments in design might be necessary. Keep an open mind about alternatives. Remember, experimentation can lead to unexpected innovations.

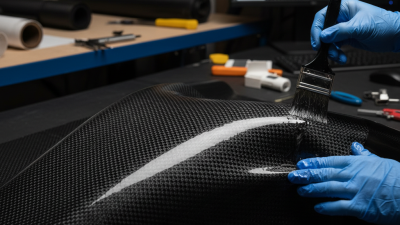

Cutting and shaping carbon fiber laminate sheets can be challenging. According to industry data, improper techniques can lead to injuries and material waste. The fibers are strong yet require careful handling. Personal protective equipment, such as gloves and masks, is essential during this process. This minimizes exposure to dust and sharp edges.

There are various methods to cut these sheets. Common techniques include using a diamond blade saw or water jet cutting. Each method has pros and cons. For example, saws create dust, while water jets may offer precision but can be expensive.

It's crucial to choose the right tool based on your project’s needs. Remember to measure twice before making any cuts. It’s easy to make mistakes, especially with intricate designs.

Shaping involves techniques like sanding and heating. Heating can help achieve curves but often risks damaging the structural integrity of the laminate. An optimal temperature of about 150°C is recommended. However, this requires a careful balance. Too much heat can weaken the material.

It's vital to test small pieces before committing to larger sections. Always document your process to reflect on what methods worked best.

When working with carbon fiber laminate sheets, bonding and finishing are crucial for optimal results. The right adhesive can enhance the material’s strength. According to a recent industry report, proper bonding techniques can increase structural integrity by up to 30%. Always ensure surfaces are clean and free of debris before applying adhesive. This small detail is often overlooked but plays a significant role.

Tips: Choose an epoxy adhesive that is specifically formulated for composite materials. This ensures a strong bond and minimizes chances of delamination. Using clamps can help secure the laminate during the curing process, allowing for even distribution of pressure.

Finishing is equally important in design projects. Sanding the edges can prevent chipping. Many underestimate the benefits of smooth edges. A rough finish may compromise aesthetics and functionality. A fine-grit sandpaper can provide that polished look without damaging the laminate.

Tips: Consider using a clear coat to protect the surface. This not only enhances durability but also gives a sleek appearance. Remember to test any finish on a scrap piece first to avoid unexpected results.