-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the realm of modern engineering and design, the choice of materials can significantly impact the success and functionality of a project. Among the various options available, the Rectangular Carbon Tube has emerged as a highly favored solution for a multitude of applications. Renowned for their strength-to-weight ratio, these tubes offer unparalleled durability while maintaining a lightweight profile, making them ideal for projects that prioritize efficiency and structural integrity.

The unique geometry of Rectangular Carbon Tubes also presents a variety of benefits. Their shape allows for easy integration into flat or angular designs, facilitating innovative architecture and machinery. Furthermore, the exceptional tensile strength of carbon fiber ensures that these tubes can withstand harsh conditions while minimizing the risk of deformation or failure over time. As such, engineers and designers are increasingly turning to Rectangular Carbon Tubes, not only for their mechanical advantages but also for their aesthetic potential in high-performance applications.

In conclusion, the decision to choose Rectangular Carbon Tubes for your next project can lead to significant enhancements in both performance and design versatility. With their superior characteristics and adaptability, these tubes are set to redefine conventional approaches in various industries, paving the way for groundbreaking innovations.

Rectangular carbon tubes offer a unique combination of strength, lightweight properties, and versatility that make them an ideal choice for various engineering applications. One of the primary benefits of these tubes is their structural integrity. The rectangular cross-section provides greater stiffness and resistance to buckling compared to circular tubes of the same weight, allowing engineers to create robust frameworks that can withstand significant loads and challenges. This characteristic is particularly beneficial in industries such as aerospace, automotive, and civil engineering, where safety and performance are paramount.

Another significant advantage of rectangular carbon tubes is their efficient use of space and material. The flat surfaces of rectangular tubes facilitate easier integration into complex assemblies, making them suitable for a wide range of applications from structural supports to fluid transport systems. Additionally, the anisotropic properties of carbon fiber allow for tailored strength and stiffness, enabling designers to optimize the material for specific performance requirements. The lightweight nature of these tubes not only contributes to reduced overall project weight but also enhances energy efficiency, which is crucial for sustainable engineering solutions.

Rectangular carbon tubes present a unique blend of material properties that make them ideal for a variety of applications. One of the most compelling advantages is their high strength-to-weight ratio, which exceeds that of many traditional materials. According to a 2022 report by the Composites Industry Association, carbon fiber composites have a tensile strength of around 600 MPa, significantly higher than aluminum at approximately 200 MPa. This superior strength allows for thinner sections in designs without compromising structural integrity, which can lead to weight savings and improved efficiency in applications ranging from aerospace to automotive engineering.

In addition to their strength, rectangular carbon tubes boast excellent stiffness and fatigue resistance. A study published in the Journal of Materials Science indicated that carbon fiber exhibits stiffness values up to 70 GPa, compared to steel's 210 GPa; however, the lightweight property reduces the overall load in dynamic applications. Furthermore, carbon materials demonstrate remarkable resistance to cyclic loading, ensuring a longer lifespan than metals, which can endure fatigue over time. The integration of rectangular carbon tubes in structural designs not only enhances performance but also provides the potential for innovative engineering solutions that require a combination of weight efficiency and durability.

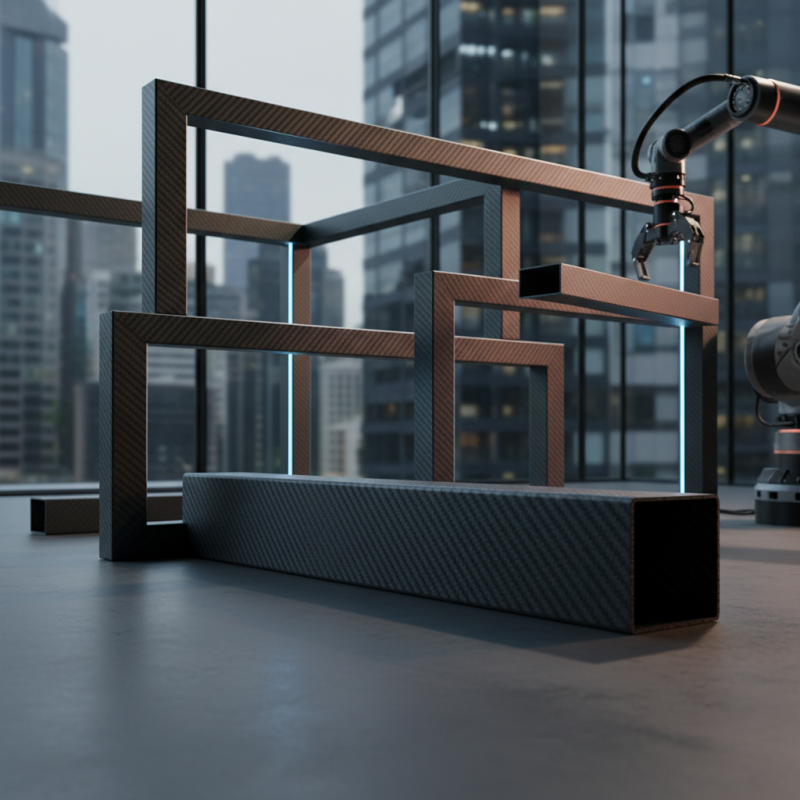

When embarking on a new project, the design flexibility offered by rectangular carbon tubes is unparalleled. These tubes come in a variety of dimensions and wall thicknesses, allowing engineers and designers to tailor their choices to meet specific project requirements. The geometric configuration of rectangular tubes not only provides efficient space utilization but also permits the seamless integration of components, making them ideal for bespoke solutions. Whether constructing lightweight frames, structural supports, or intricate designs, the versatility of these tubes allows for innovative approaches that standard materials simply cannot match.

Customization options further enhance the appeal of rectangular carbon tubes. They can be manufactured to precise specifications, ensuring that each tube fits the unique parameters of your project. This capability reduces the need for additional modifications or reinforcements, streamlining the construction process. In addition, the ability to specify finishes, surface treatments, and additional features such as pre-drilled holes or specific angles means that designers can achieve not only functionality but also aesthetic appeal. This level of personalization enables projects to reflect the vision and creativity of designers while maintaining structural integrity and performance.

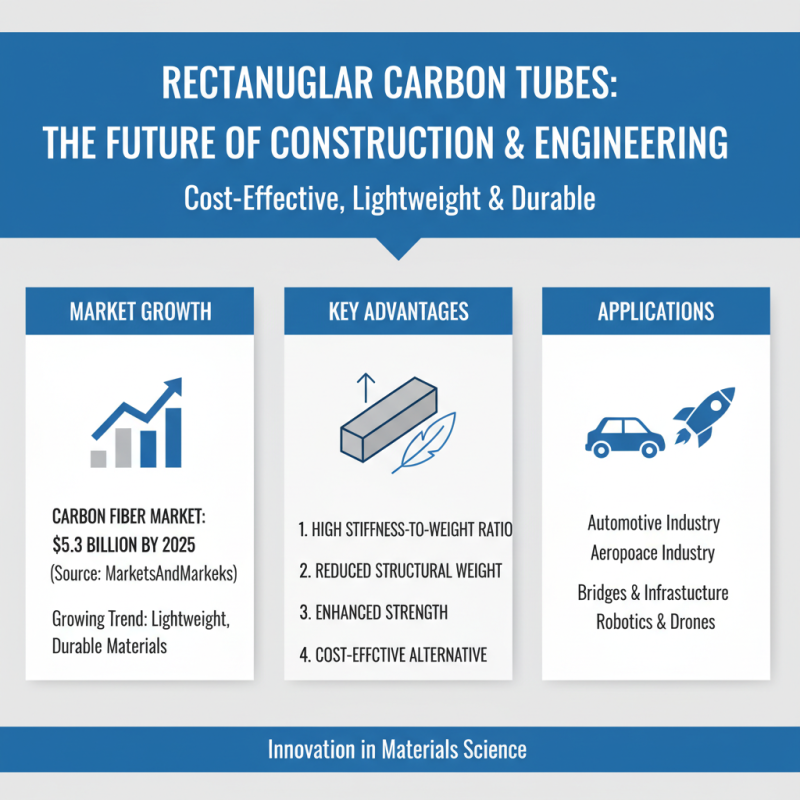

When considering materials for construction and engineering projects, the cost-effectiveness of rectangular carbon tubes stands out among alternatives. According to a report by MarketsandMarkets, the carbon fiber market is expected to reach $5.3 billion by 2025, indicating a growing trend toward utilizing lightweight and durable materials. Rectangular carbon tubes, with their high stiffness-to-weight ratio, not only reduce the overall weight of structures but also enhance their strength, making them an ideal choice for various applications such as automotive and aerospace industries.

Moreover, the initial investment in rectangular carbon tubes may be offset by their long-term benefits. A study from the Composite Materials Handbook highlights that carbon fiber components can lead to a 30% reduction in maintenance costs due to their superior resistance to corrosion and fatigue. This durability translates into lower lifecycle costs, making rectangular carbon tubes not only a viable option for project budgets but also a strategic investment for future savings. Thus, the combination of reduced material weight, increased strength, and lower maintenance expenses underscores the financial advantages of choosing rectangular carbon tubes for upcoming projects.

Rectangular carbon tubes are increasingly becoming popular across various industries due to their unique properties and versatile applications. In the automotive sector, these tubes are valued for their lightweight yet robust nature, enabling significant weight savings while maintaining structural integrity. The aerospace industry also benefits from rectangular carbon tubes, which are used in the construction of lightweight components that enhance fuel efficiency and performance. Additionally, in the construction field, they serve as vital elements in frame designs, providing strength without excessive weight, which is essential for modern architectural demands.

Tips: When selecting rectangular carbon tubes for your project, consider the specific load-bearing requirements and environmental conditions they will face. Understanding the strength-to-weight ratio can help optimize your design while ensuring safety and functionality.

Another significant application can be found in the sporting goods industry. Rectangular carbon tubes are often utilized in the production of high-performance equipment, such as bicycles and outdoor sports gear. Their durability and ability to be molded into various shapes make them ideal for crafting finely tuned performance pieces. Furthermore, furniture designers are now exploring these tubes for innovative designs that capitalize on both aesthetics and stability.

Tips: Always evaluate the fabrication methods available for carbon tubes, as this can affect both cost and the final product's performance. Partnering with skilled manufacturers can lead to optimized designs that meet your specific project needs.