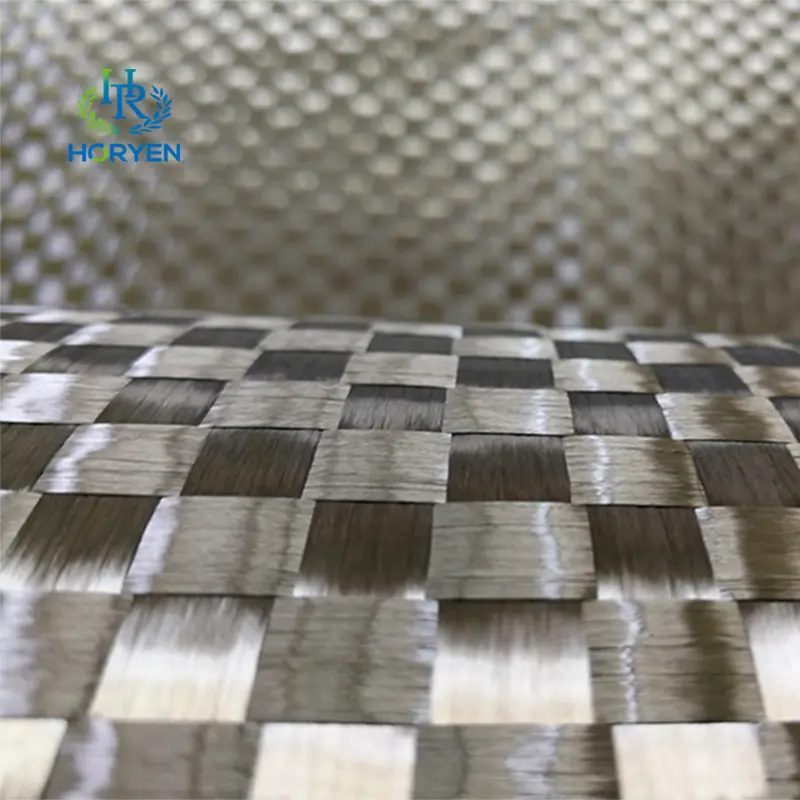

12k 100g Ultra-lightweight Carbon Fiber Spread ...

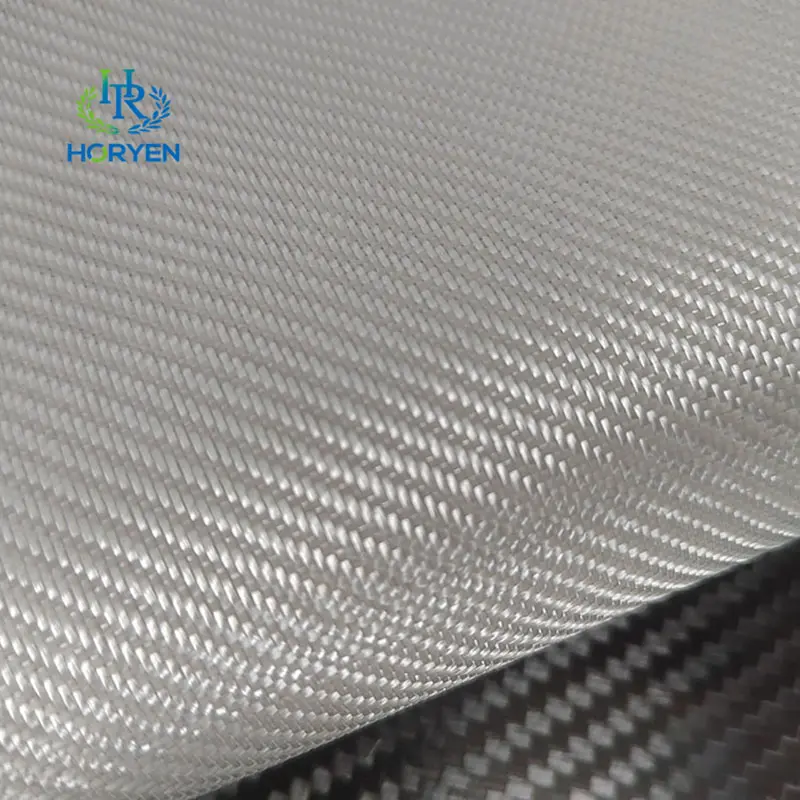

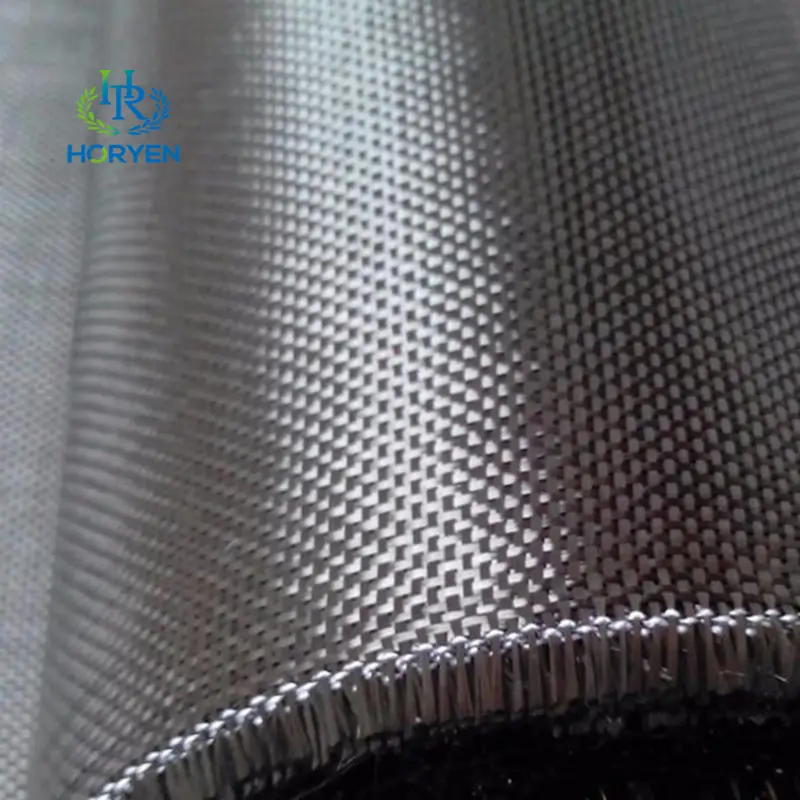

The advantage of carbon fiber spread tow fabric lies in its unique fiber distribution morphology. Compared with traditional carbon fiber fabric, the widening process results in a highly uniform arrangement of fibers in the plane, significantly improving the specific strength and stiffness of the composite material. Due to the thinner fiber layer and reduced gaps.

In addtion, the advantage of the flatness of the widened fabric surface enables it to present a smooth appearance after molding, especially suitable for scenarios such as aerospace shells and high-end car bodies that require strict appearance and aerodynamic performance.

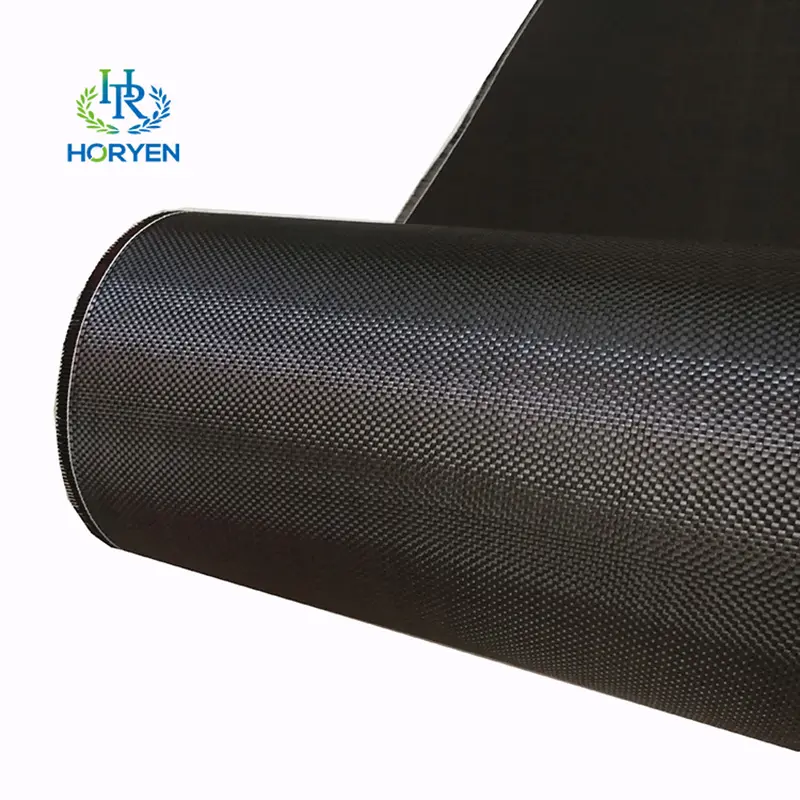

12K 200gsm Plain Spread Tow Carbon Fiber Cloth ...

Carbon Fiber Spread Tow Fabric is a high-performance composite material reinforced fabric that optimizes fiber distribution through advanced processes. Its core lies in processing traditional carbon fiber bundles (usually tightly bundled from thousands of single filaments) through mechanical or air flow unfolding technology, forming a flat strip structure with significantly increased width (up to 50 millimeters or more) and extremely thin thickness (single layer thickness can be as low as 0.02 millimeters). This process not only breaks the traditional circular cross-sectional shape of fiber bundles, but also evenly spreads the fibers into nearly single-layer continuous sheets, greatly reducing the overlap and gaps between fiber bundles.

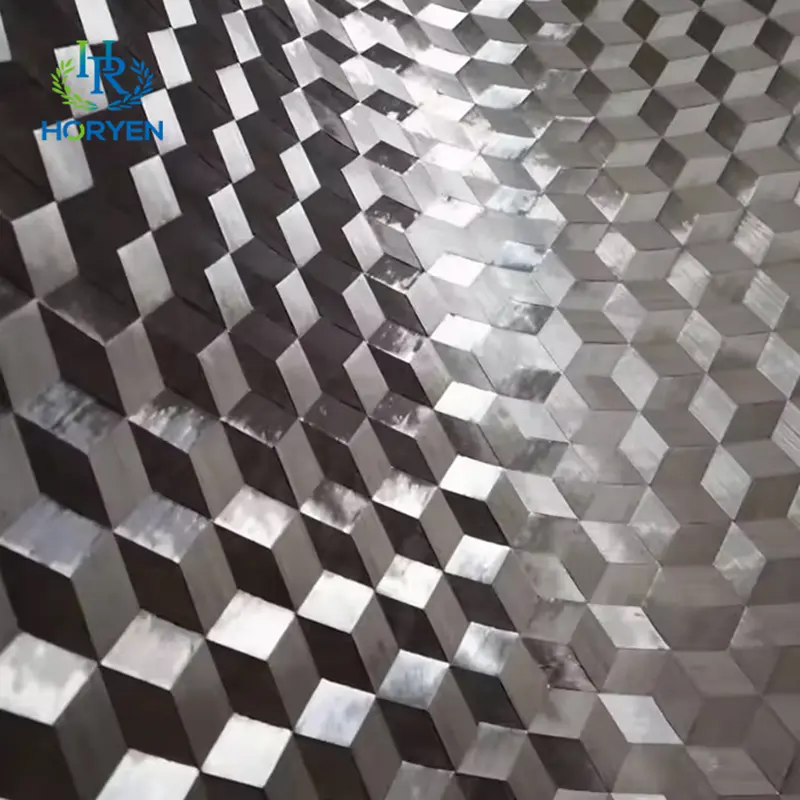

Triaxial 3D 12k 150gsm Spread Tow Carbon Fiber ...

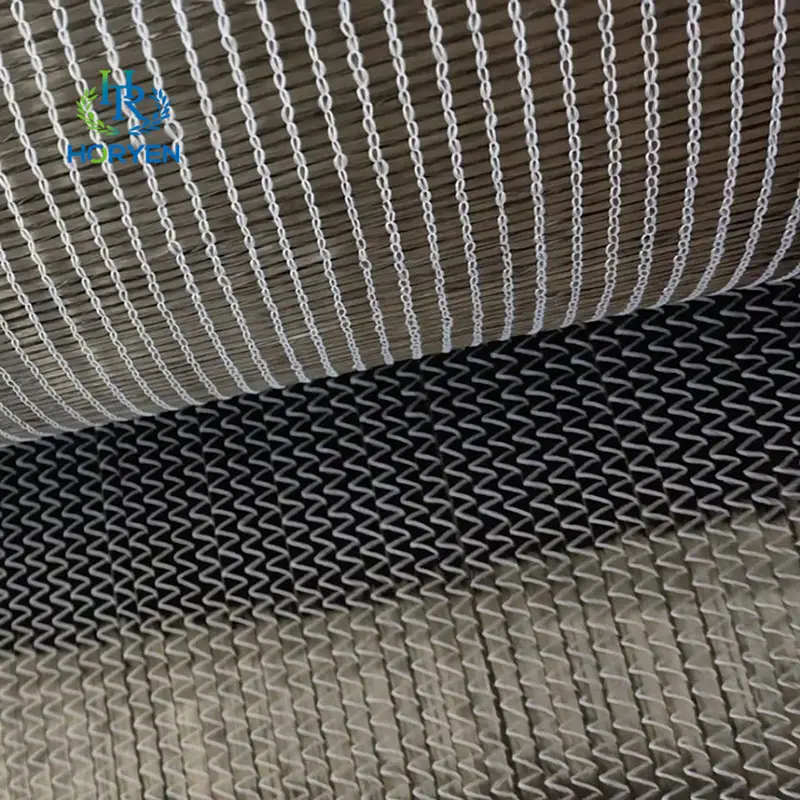

Traditional triaxial fabrics are made by interweaving two sets of mutually perpendicular yarns on the same side.

Triaxial fabric is a fabric made up of three yarns interwoven at a 60 degree angle in the same plane. Due to the special structure of three-axis fabric interwoven with three system yarns, it has good fabric structural stability and the same mechanical characteristics of all directional forces, which disperses the forces acting on the fabric on the three axes and greatly improves the load-bearing volume of the fabric.

The performance indicators such as fracture strength, tear strength, and fracture strength of fabrics are higher than those of biaxial fabrics. Strength advantage, strong anti diagonal pulling ability, high flexibility, and good fatigue resistance.

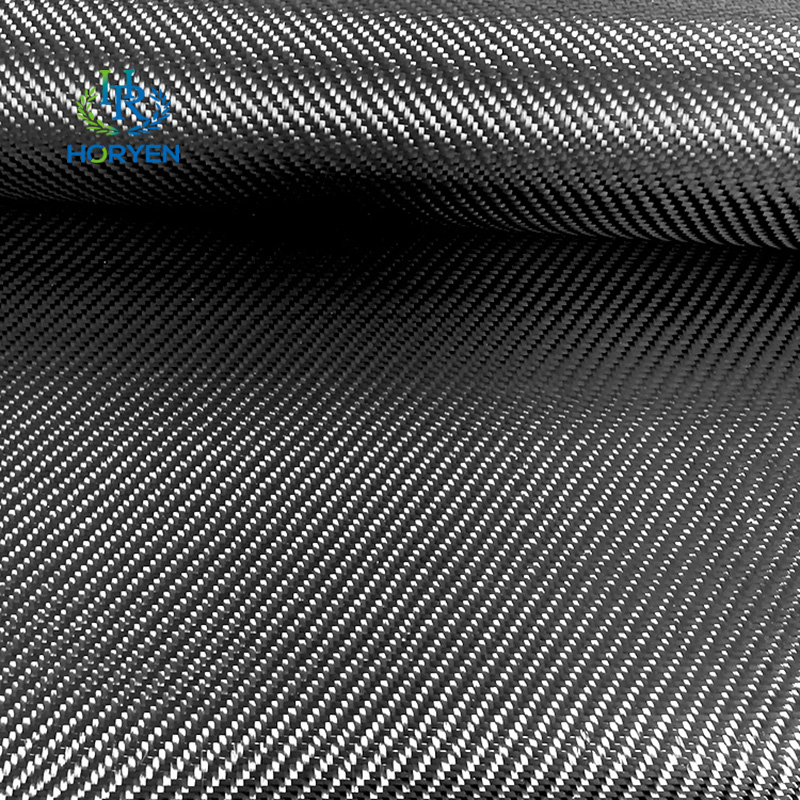

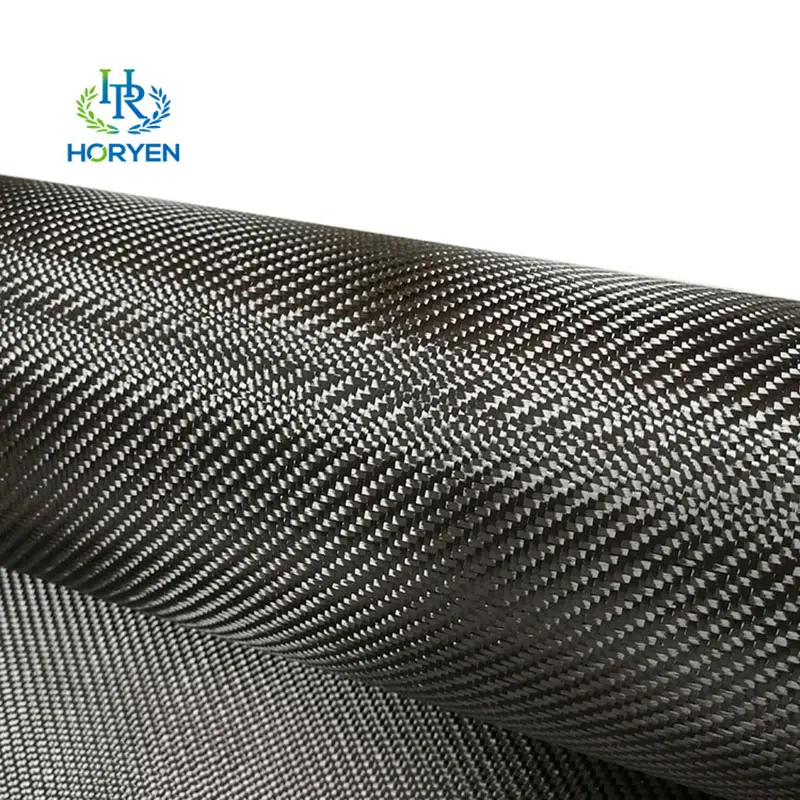

Hot Selling 1.5m Width 3k 240g Twill Carbon Fib...

Carbon fiber cloth is an advanced composite material made of carbon fiber. Its single filament diameter is only 5-10 microns, but it exhibits specific strength characteristics that exceed steel by 5-8 times, with a tensile strength of up to 3500-7000 MPa and an elastic modulus exceeding 230 GPa. By using 0 °/90 ° orthogonal or ± 45 ° diagonal weaving techniques, the mechanical property distribution in different directions can be customized. In terms of chemical stability, carbon fiber cloth is resistant to strong acid and alkali erosion, with a fatigue resistance of over 10 ^ 7 cycles, and maintains a strength retention rate of over 90% in extreme temperature ranges from -196 ℃ to 650 ℃. This disruptive material performance makes it a core reinforcement material for high-end equipment such as spacecraft fairings and high-speed train bogies, achieving a weight reduction of 30% -50% while improving structural reliability.

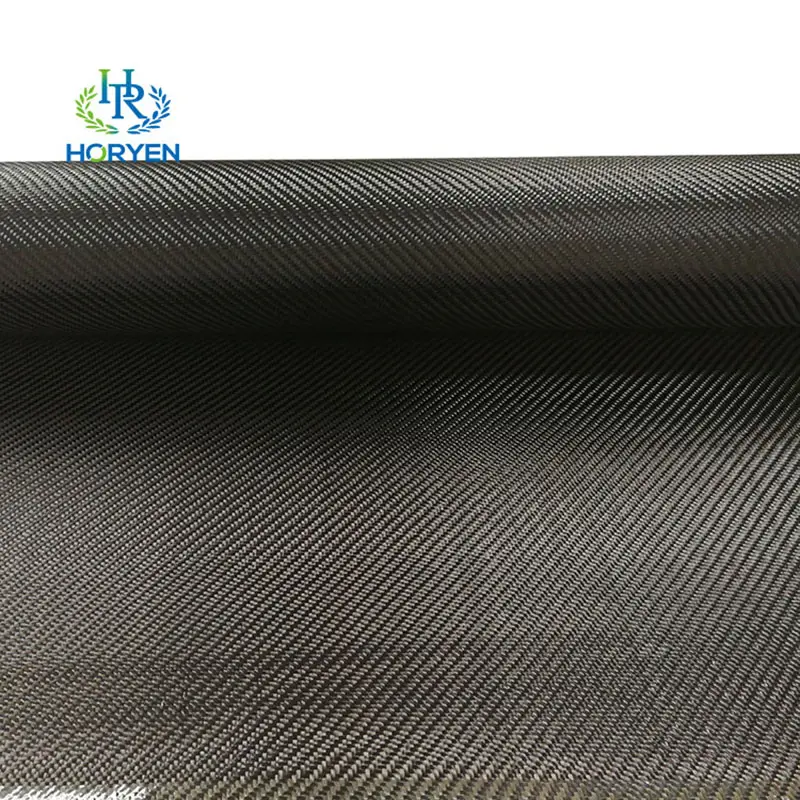

Width 1.5m 3k 220g Twill Carbon Fiber Fabric Cloth

Carbon fiber cloth is a material woven from carbon fibers, with carbon fibers being its main component. It has the characteristics of high strength, high modulus, high temperature resistance, and corrosion resistance. Due to its extremely high strength and stiffness, carbon fiber cloth can be used to manufacture various high-strength and high-performance products.

With the advancement of materials science, carbon fiber cloth is being explored for use in more cutting-edge fields, such as wearable devices, medical prosthetics, robot structural components, etc. Its lightweight and high-strength characteristics make it one of the key materials for future intelligent equipment. At the same time, the research and development of environmentally friendly carbon fiber cloth is also being promoted, such as using recyclable resins or bio based carbon fibers to reduce carbon footprint and meet the needs of sustainable development.

Double Faced 6k 320g Plain Weave Carbon Fiber F...

Carbon fiber fabric can be customized according to the needs of different industries, such as adjusting fiber density (3K, 6K, 12K, etc.), thickness, weaving method (plain weave, twill weave, satin weave) or adding special coating (flame retardant, UV resistant, wear-resistant, etc.). For example, prepreg resin carbon fiber cloth can be directly hot pressed, greatly improving production efficiency; Flexible carbon fiber felt is suitable for complex curved surface covering and is widely popular in car modification and drone shell manufacturing.

Unlike traditional fiber materials, carbon fiber fabric can maintain stability in high temperature environments, and some models can even withstand short-term high temperatures above 1000 ° C. It is suitable for spacecraft thermal protection or industrial heat-resistant components. Meanwhile, carbon fiber cloth has excellent conductivity and can be used for electromagnetic shielding, static dissipation, or heating element manufacturing. It is widely used in electronic equipment, new energy batteries, and military industries.

High Quality 3k 200g Plain Carbon Fiber Cloth Roll

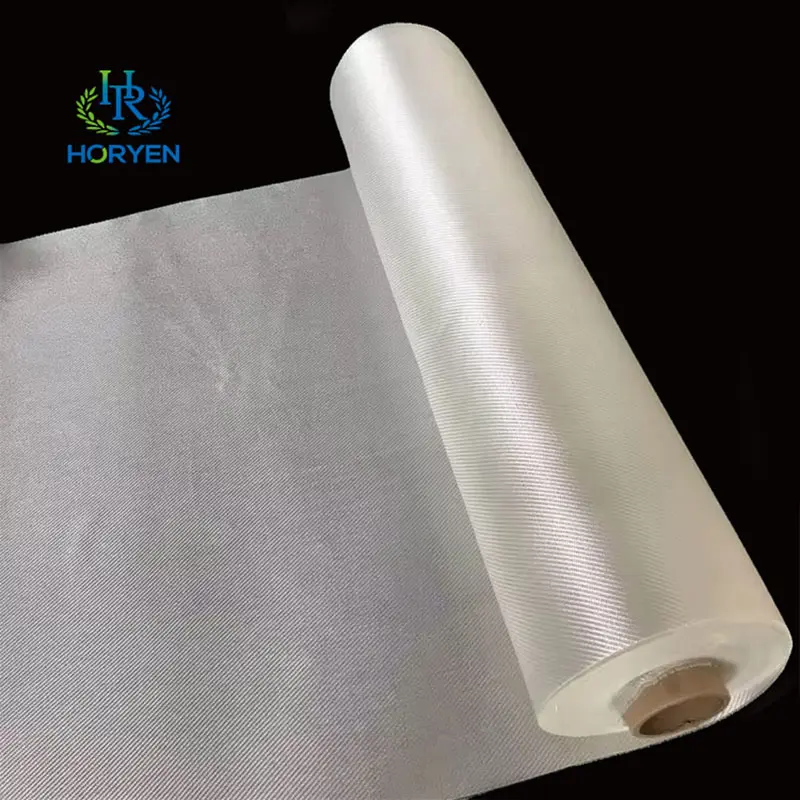

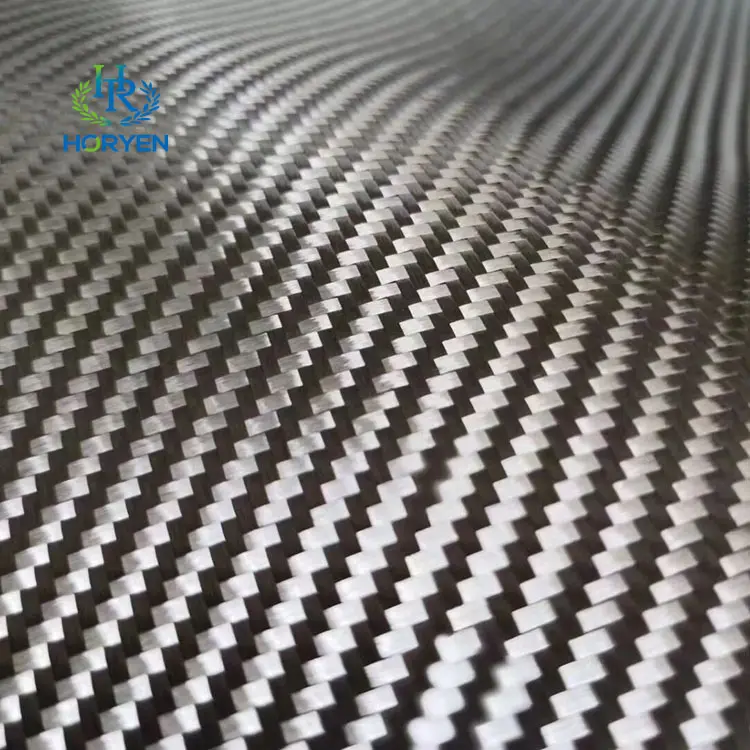

Carbon fiber cloth adopts plain weave, twill weave or unidirectional weaving technology to ensure uniform fiber distribution and controllable mechanical properties. For example, unidirectional carbon fiber cloth provides extremely high tensile strength in a single direction and is suitable for structural components subjected to unidirectional stress; Multi axial carbon fiber cloth achieves multi-directional force balance by stacking multiple layers of fibers at different angles, making it suitable for complex load environments. In addition, the surface of carbon fiber cloth is smooth and easy to bond with resin, forming high-strength composite materials.

Factory Sale 1K 90g Plain Carbon Fiber Fabric

Carbon fiber fabric is an advanced material made from high-purity carbon fiber bundles through a special weaving process, with extremely high strength to weight ratio. Its density is only 1/5 of steel, but its tensile strength far exceeds that of steel, making it a good choice in fields such as aerospace, automotive lightweighting, and sports equipment. In addition, carbon fiber fabric has excellent corrosion resistance and fatigue resistance, and can maintain stable performance for a long time even in harsh environments, greatly extending the service life of structural components.

High Stability 3K Twill 240g Width 1m Dry Carbo...

The core competitiveness of carbon fiber fabric lies in its "lightweight as feather, strong as steel, and intelligent as core" - its lightweight, high strength, and functional designability make it the cornerstone of high-end manufacturing and green technology. In the future, with breakthroughs in low-cost manufacturing technologies (such as large fiber bundles) and recycling solutions, carbon fiber fabric will further penetrate from "cutting-edge fields" such as aerospace to the civilian market (such as building reinforcement and consumer electronics), promoting the material revolution to a deeper level of development.

The application of carbon fiber fabric has evolved from a "laboratory material" to a "versatile" in modern industry, with its core value lying in "promoting high efficiency with lightweight and breaking through scene limitations with multifunctionality". With technological advancements, carbon fiber fabric will continue to unleash its potential in future fields such as carbon neutrality, smart wearables, and deep space exploration, becoming a key link between materials science and industrial upgrading.

Width 1m 3K Twill 220g Carbon Fiber Cloth Roll

Carbon fiber cloth has characteristics such as high strength, lightweight, excellent heat resistance, and corrosion resistance. Carbon fiber cloth is a high-performance material woven from carbon fibers through special processes. Its tensile strength is usually more than 5 times higher than steel and more than 2 times higher than aluminum alloy. In addition, carbon fiber cloth has a lower density than metal materials and weighs only about 1/5 to 1/4 of metal materials, making it lightweight. Carbon fiber cloth can also withstand high temperatures and has excellent heat resistance, usually able to withstand temperatures above 200 ℃. More importantly, carbon fiber cloth will not corrode due to moisture and has strong corrosion resistance, making it suitable for long-term use in harsh environments.

Lightweight 3K Twill 200g Carbon Fiber Fabric F...

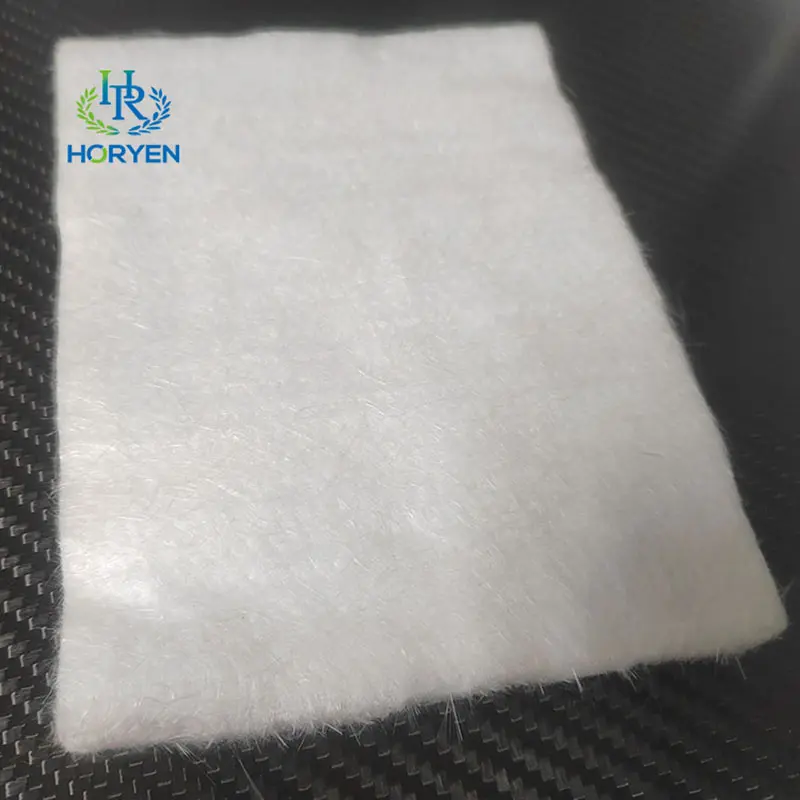

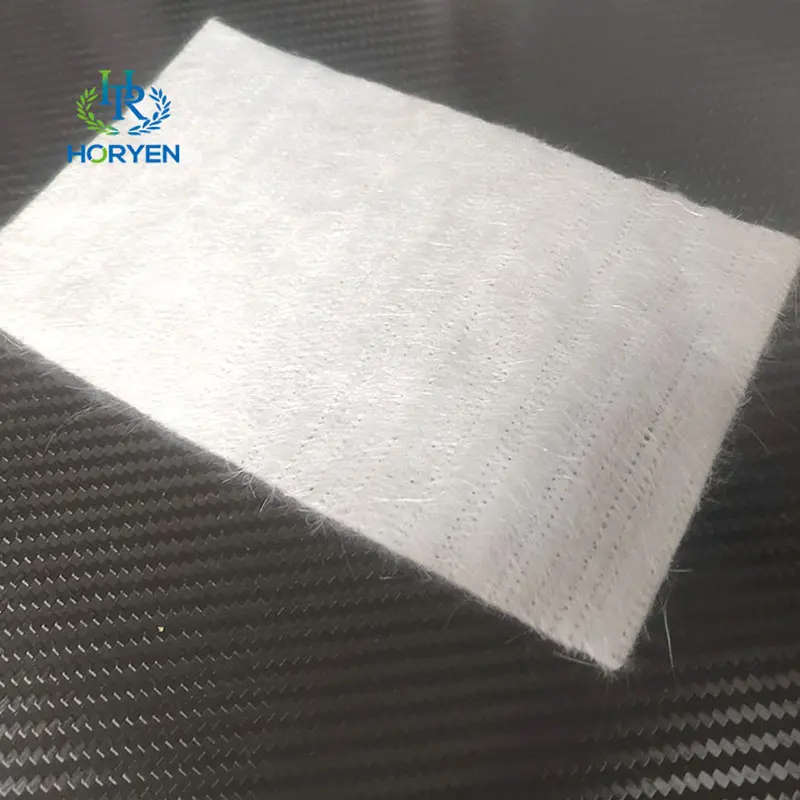

Carbon fiber fabric is a high-performance material mainly composed of carbon elements, with characteristics such as high temperature resistance, friction resistance, thermal conductivity, and corrosion resistance. Its appearance is fibrous, soft, and can be processed into various fabrics. Carbon fiber fabric has a low density, high specific strength and modulus, and is commonly used as a reinforcement material, such as in composites with resins, metals, ceramics, and carbon, to manufacture advanced composite materials.

The raw materials for carbon fiber are generally organic fibers with high carbon content. By subjecting these raw materials to a series of complex processes such as high temperature and stretching, carbon fibers can be obtained. Then weave these carbon fibers into cloth according to a certain weaving method. In this process, every step must be accurately grasped.

Construction Reinforcement 0 90 Degree Carbon F...

Carbon fiber biaxial fabric is a reinforced composite material made of carbon fibers, whose core feature is that the fibers are arranged in parallel in two specific directions (usually 0 ° and 90 °), and formed into high-performance composite materials after resin impregnation and curing.

Carbon fiber biaxial cloth is a new type of fiber material with high strength and high modulus of carbon content of more than 95%.

Carbon fiber is "soft on the outside and tough on the inside", lighter than aluminum, but stronger than steel, 7 times stronger than steel.And has the characteristics of corrosion resistance, high modulus, in the national defense industry and civil are important materials.